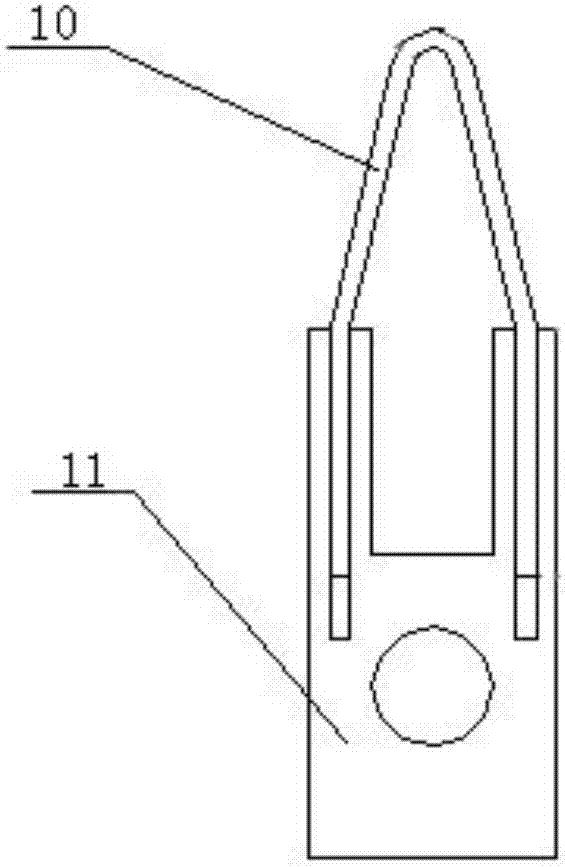

Automatic rope sticking equipment for piano shaft brackets

A shaft frame and automatic technology, which is applied in the direction of instruments, stringed instruments, and devices for coating liquid on the surface, etc., can solve the problems of high quality requirements for workers, low production efficiency, and unstable quality, so as to ensure the accuracy of process requirements and improve The effect of production efficiency and consistent rope length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

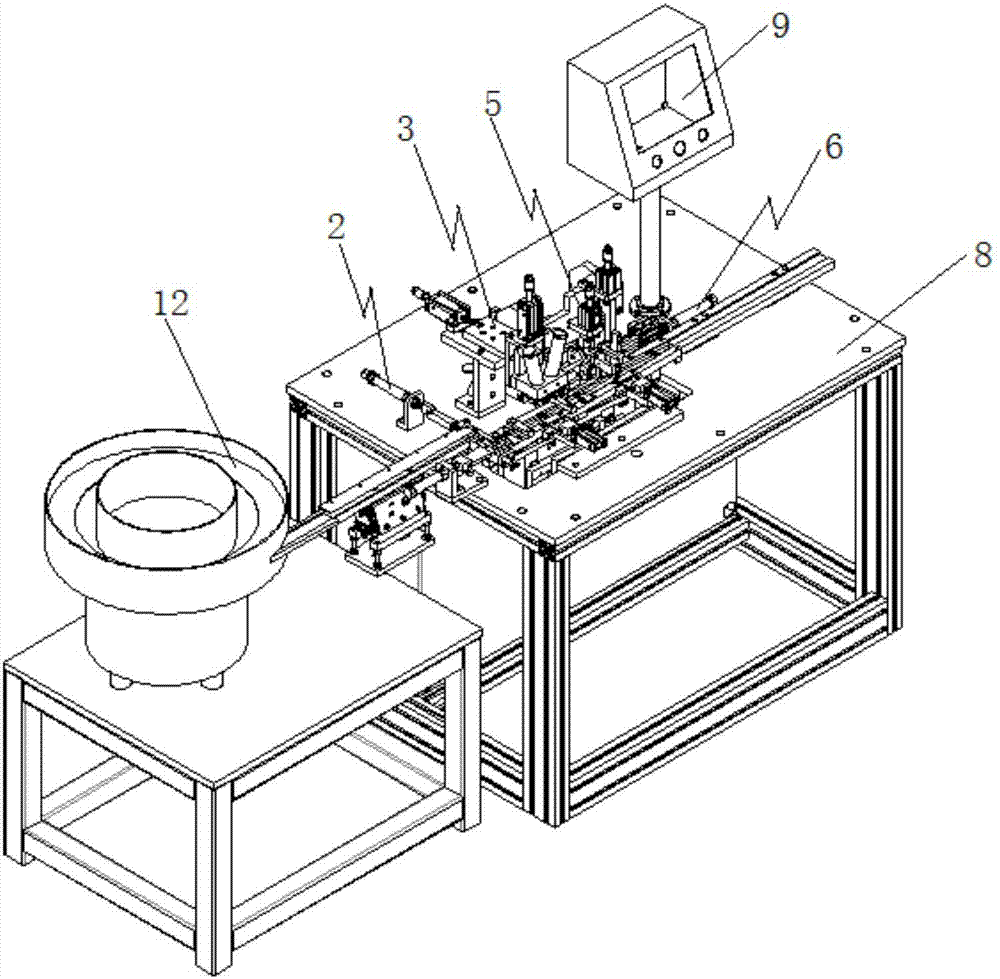

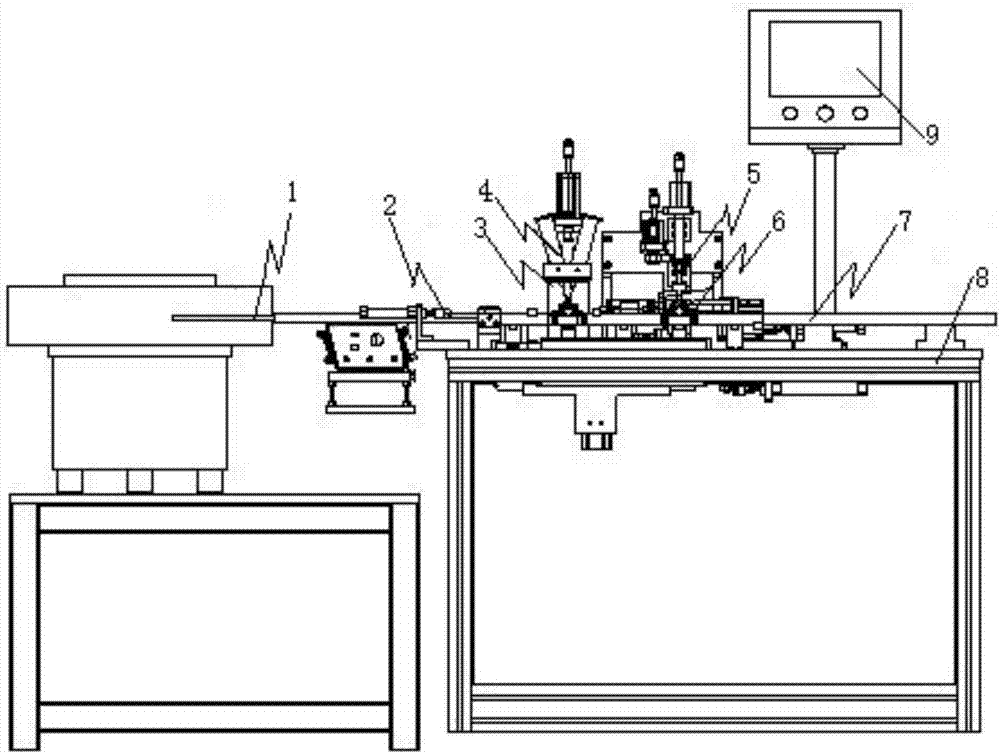

[0036] Piano shaft frame automatic rope sticking equipment, including: discharging mechanism, feeding mechanism, glue dispensing mechanism, rope taking and cutting mechanism, forming and pressing rope mechanism, material taking and conveying mechanism and an electric control system for controlling the action of each mechanism.

[0037] The discharge mechanism includes a discharge vibration plate, a direct vibration plate and a discharge trough; the discharge trough is connected to the discharge port of the discharge vibration plate, and the direct vibration plate is arranged at the middle bottom of the discharge trough. The shaft frame to be processed is vibrated and discharged into the discharge trough sequentially from the discharge port of the discharge vibration plate, and is vibrated and transported forward in the discharge trough.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com