A kind of led packaging structure

A technology of LED packaging and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of decreased quantum efficiency, increased production costs, insufficient brightness of light source lighting, etc., to improve light extraction efficiency, reduce production costs, Avoid direct contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

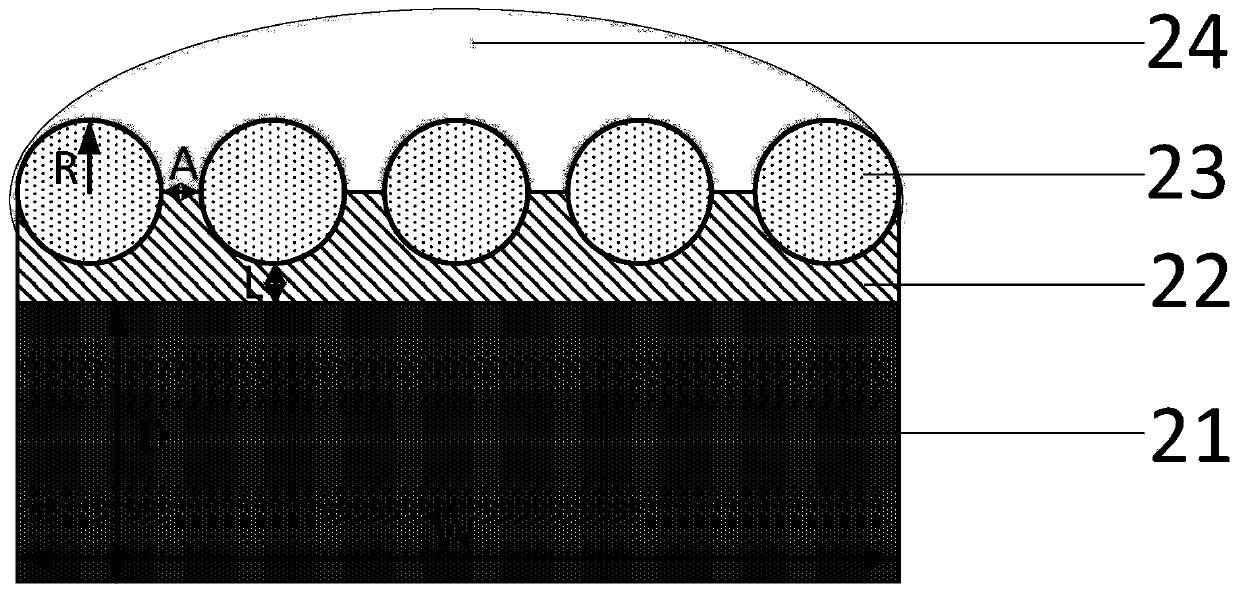

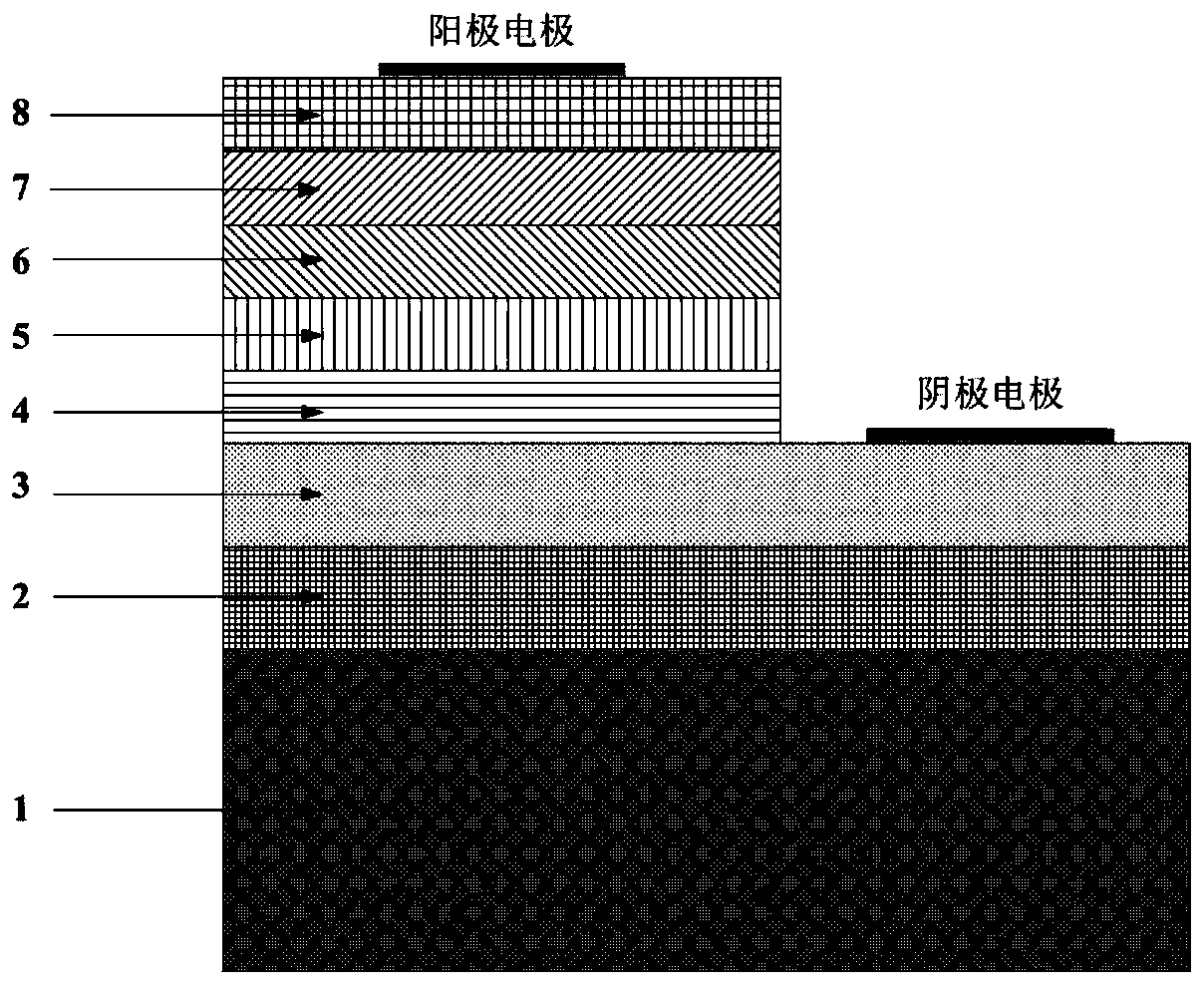

[0031] Please refer to figure 1 , figure 1 Schematic diagram of the structure of the LED package structure provided by the embodiment of the present invention; wherein, the LED package structure provided by the embodiment of the present invention, the package structure includes: a package substrate 21; an LED chip is fixed on the package substrate 21; specifically Yes, the LED chip is a GaN-based blue light chip.

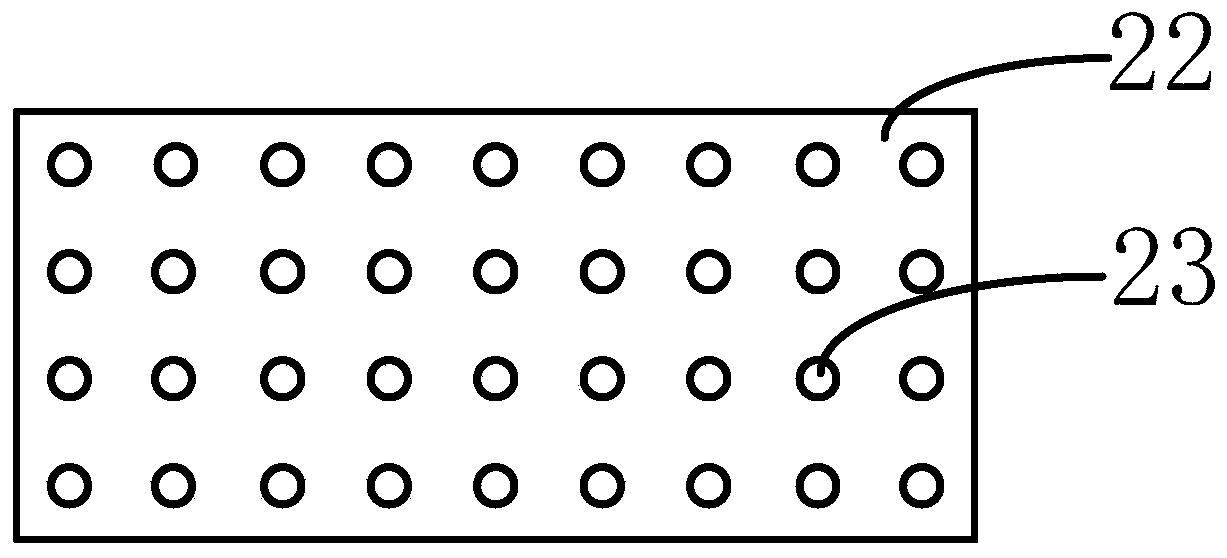

[0032] Further, the package structure also includes a silica gel layer, wherein in the embodiment of the present invention, the silica gel layer includes a first silica gel layer 22 and a second silica gel layer 24 sequentially arranged on the upper surface of the LED chip, that is, the embodiment of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com