Formula and making method of camel milk powder

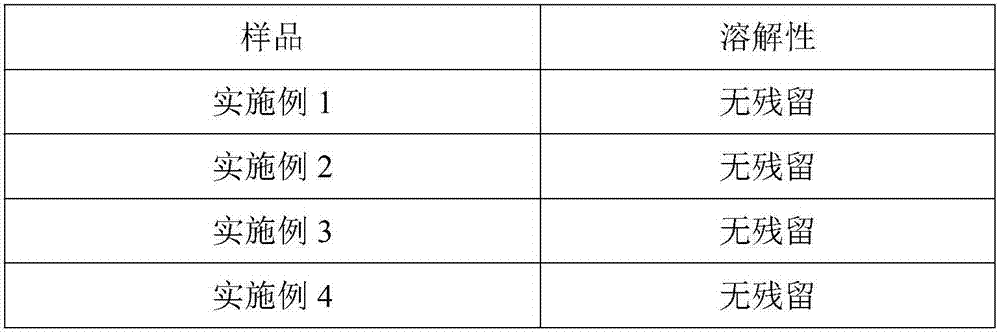

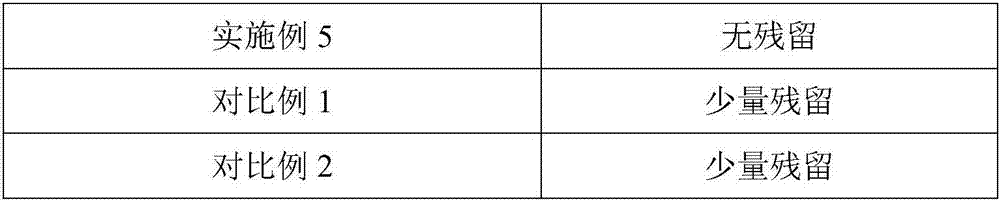

A technology for camel milk and milk powder, which is applied in milk preparations, dairy products, applications, etc., can solve the problems of poor solubility of camel milk powder at room temperature, and achieve the effects of good solubility at room temperature, high content of active ingredients, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of camel milk powder is characterized in that, comprises the following steps:

[0023] S1. In parts by weight, add 320 parts of fresh camel milk into a centrifuge tank, centrifuge at a speed of 7500r / min for 15min, keep the centrifugation temperature at 20°C, obtain skimmed camel milk after centrifugation, and then centrifuge under a pressure of 100MPa The skimmed camel milk is sterilized once to obtain sterilized raw milk, and the temperature of the first sterilization is 65°C;

[0024] S2. In parts by weight, the sterilized raw milk prepared in S2 is divided into 3 equal parts, 2 equal parts sterilized raw milk, 6 parts of oat dietary fiber, 4 parts of galactooligosaccharides, 8 parts of whey protein powder, 0.23 1 part of vitamin A powder, 0.3 part of vitamin D powder, 0.5 part of nucleotides, 0.06 part of milk calcium, and then added to a homogenizer for homogenization. The homogenization temperature is 48 ° C, and the homogenization pre...

Embodiment 2

[0029] A kind of preparation method of camel milk powder is characterized in that, comprises the following steps:

[0030] S1. In parts by weight, add 300 parts of fresh camel milk into a centrifuge tank, centrifuge at a speed of 6800r / min for 18min, keep the centrifugation temperature at 10°C, obtain skim camel milk after centrifugation, and then centrifuge under a pressure of 110MPa The skimmed camel milk is sterilized once to obtain sterilized raw milk, and the temperature of the first sterilization is 68°C;

[0031] S2. In parts by weight, the sterilized raw milk prepared in S2 is divided into 3 equal parts, 2 equal parts sterilized raw milk, 5 parts oat dietary fiber, 3.5 parts galactooligosaccharides, 10 parts whey protein powder, 0.2 parts 1 part of vitamin A powder, 0.25 part of vitamin D powder, 0.7 part of nucleotides, 0.05 part of milk calcium, and then added to a homogenizer for homogenization. Baume degree, spraying again to granulate, and then freeze-drying to o...

Embodiment 3

[0036]A kind of preparation method of camel milk powder is characterized in that, comprises the following steps:

[0037] S1. In parts by weight, add 350 parts of fresh camel milk into a centrifuge tank, centrifuge at a speed of 6500r / min for 16min, keep the centrifugation temperature at 25°C, obtain skimmed camel milk after centrifugation, and then centrifuge under a pressure of 120MPa The skimmed camel milk is sterilized once to obtain sterilized raw milk, and the temperature of the first sterilization is 67°C;

[0038] S2. In parts by weight, divide the sterilized raw milk prepared in S2 into 3 equal parts, 2 equal parts sterilized raw milk, 7 parts of oat dietary fiber, 3 parts of galactooligosaccharides, 9 parts of whey protein powder, 0.25 1 part of vitamin A powder, 0.2 part of vitamin D powder, 0.6 part of nucleotides, 0.08 part of milk calcium, and then added to a homogenizer for homogenization. Baume degree, spraying again to granulate, and then freeze-drying to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com