High-temperature acid-contained smoke hydrogen chloride recovering system

A recovery system and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve the problems of waste resource utilization and achieve the effect of realizing waste resource utilization and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

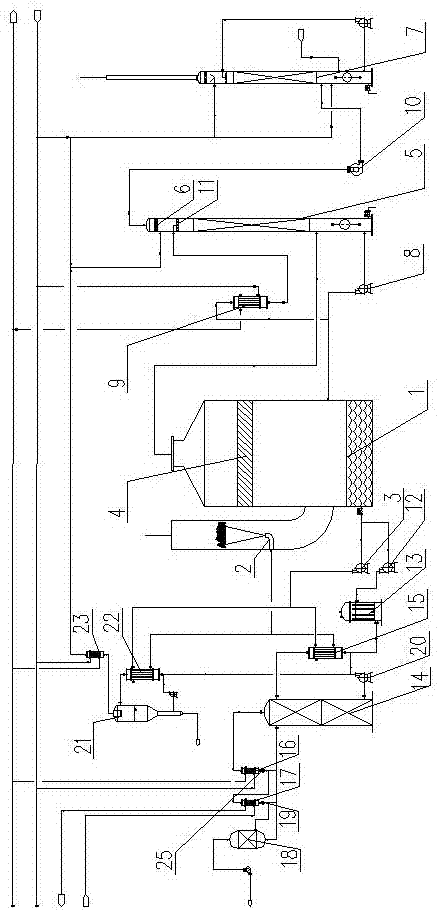

[0020] Such as figure 1 As shown, the present invention discloses a process for recovering hydrogen chloride from high-temperature acid-containing flue gas, comprising a power wave scrubber 1, a water washing tower 5, a primary cooler 16, a secondary cooler 17, a first demister 18, an lye Tower 7, the first reboiler 15, the second reboiler 22, the flash separation tank 21, the first condenser 23, the hydrochloric acid desorption tower 14, wherein the cooling medium of the primary cooler 16 is normal temperature cooling water, and the temperature is between 20-30°C, the cooling medium of the secondary cooler 17 is chilled water, and the temperature of the chilled water is 3-8°C.

[0021] The power wave scrubber 1, the water washing tower 5, and the lye tower 7 are connected successively, wherein the gas outlet of the power wave scrubber 1 is provided with a second demister 4, and the gas outlet of the water washing tower 5 is provided with a third demister 6, The temperature o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap