Hoop-bending device for stainless steel pipes

A technology of stainless steel and bending hoops, which is applied in the field of stainless steel pipe bending hoops, can solve the problems of reducing processing procedures and inconvenient picking up parts, and achieves the effect of reducing processing procedures and solving inconvenient picking up parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

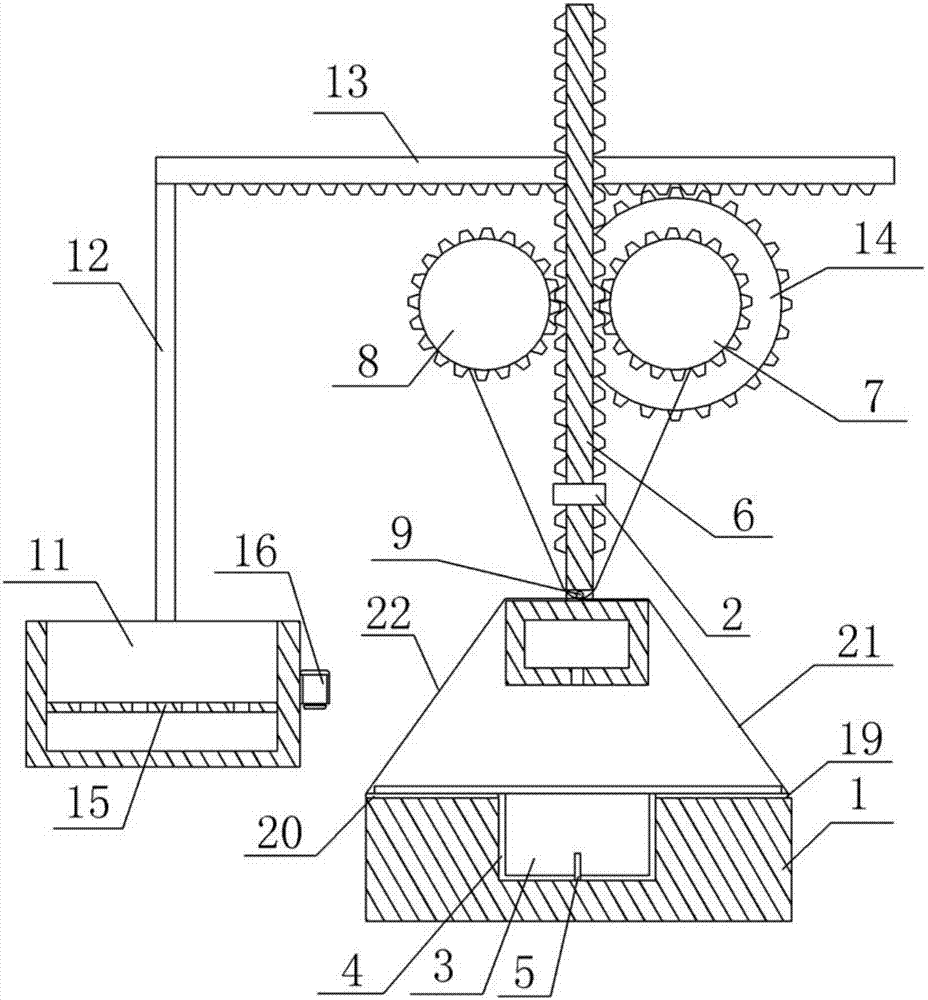

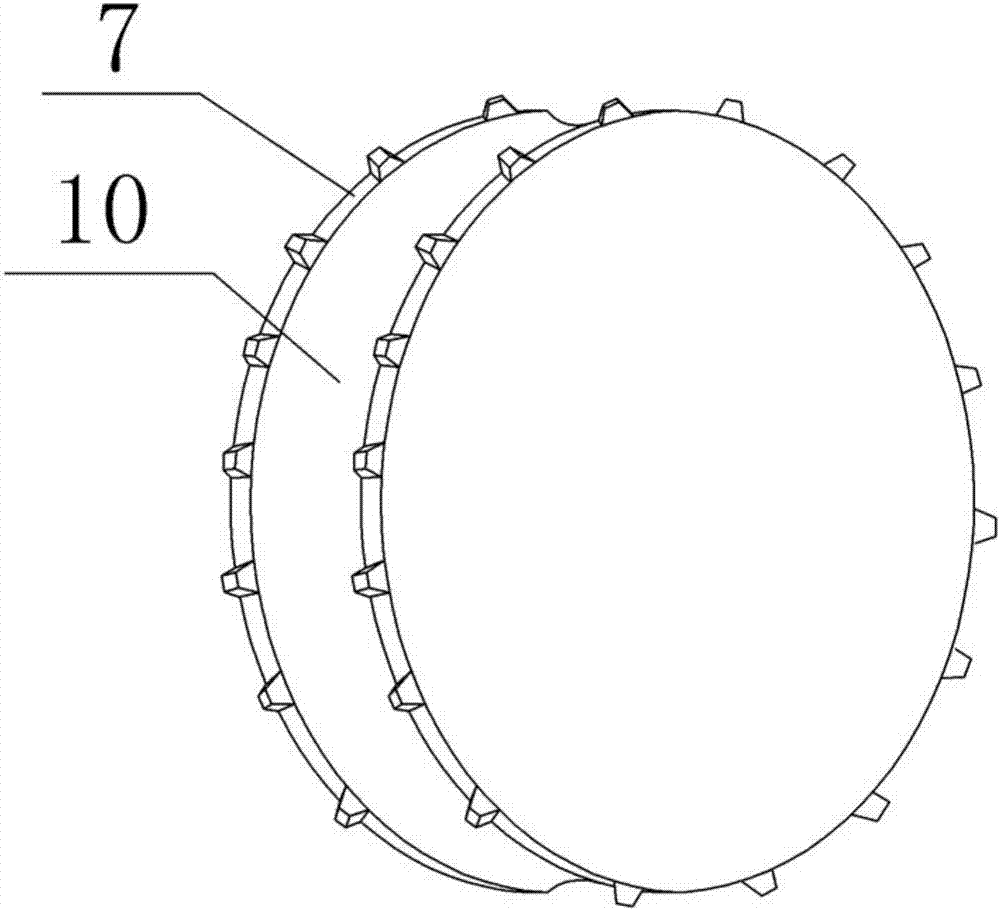

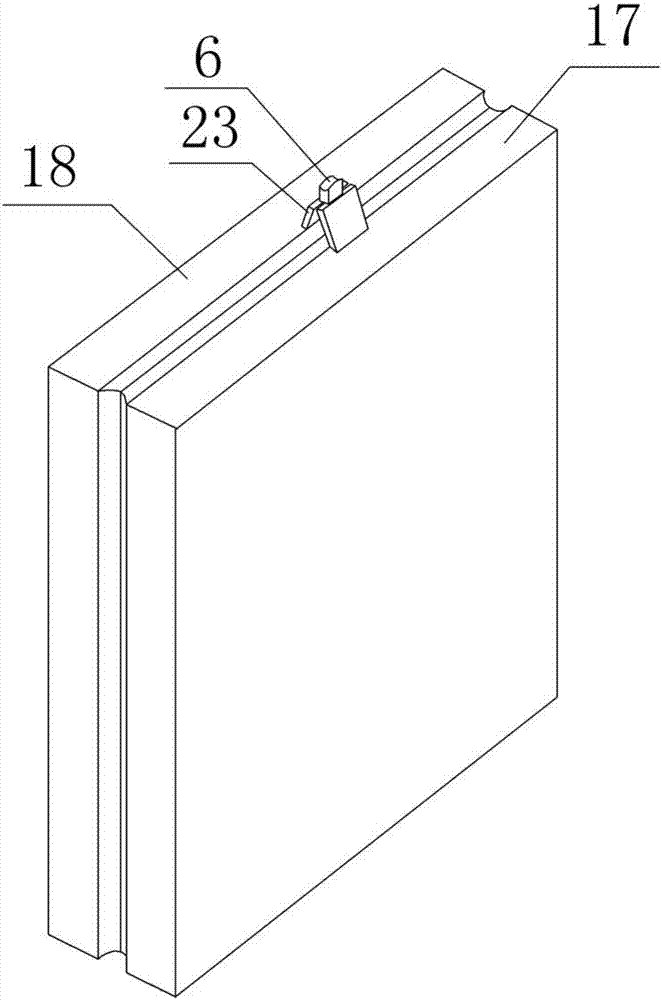

[0015] The reference signs in the accompanying drawings of the specification include: support platform 1, electromagnet 2, bending hoop groove 3, arc groove 4, hole nail 5, rack number one 6, gear number one 7, gear number two 8, pulley 9. Annular groove 10, storage box 11, support rod 12, No. 2 rack 13, No. 3 gear 14, grid 15, vibration motor 16, No. 1 bending hoop block 17, No. 2 bending hoop block 18, No. 1 Bending hoop plate 19, No. 2 bending hoop plate 20, No. 1 stay cord 21, No. 2 stay cord 22, distance-expanding block 23.

[0016] Such as figure 1 The stainless steel pipe hoop bending device shown includes a supporting platform 1, a hoop bending mechanism, an electromagnet 2, a removal mechanism and a material holding mechanism from bottom to top. Bending hoop groove 3 is arranged on the supporting platform 1, and the groove wall and groove bottom of bending hoop groove 3 are provided wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap