Ironwood disc inner ring groove milling device, groove milling method and electric wire and cable ironwood plate

A slot milling device and disc technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems that the installation process cannot be guaranteed, and achieve good cylinder flatness, reduce installation difficulty, and beautiful joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

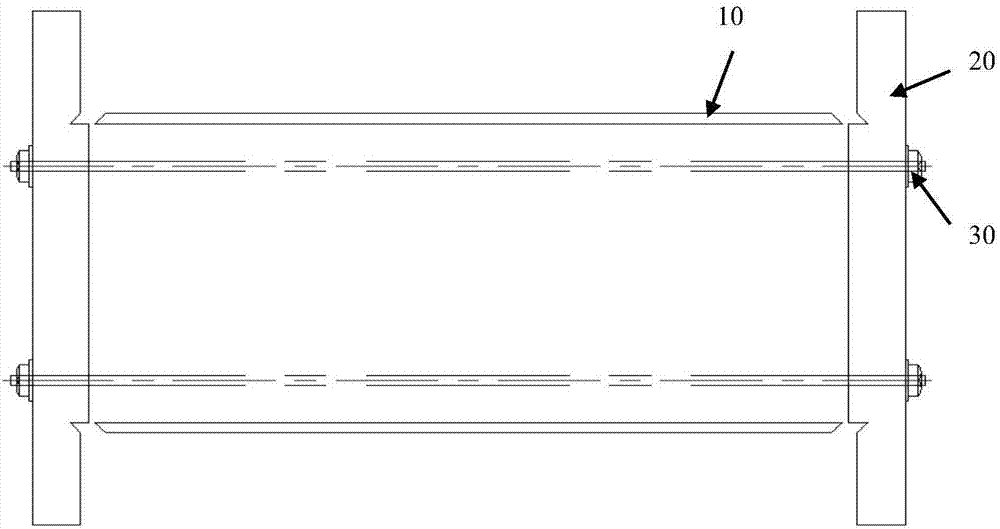

[0021] Such as figure 1 As shown, the electric wire and cable iron wood disc of the present invention includes: a plurality of cylinder bars 10, two iron wood discs 20 arranged oppositely, and a fixing screw 30 connecting the two iron wood discs 20; wherein, each iron The inner circle of the wooden discs 20 is provided with a circle of milling grooves, and a plurality of cylindrical bars 10 are sequentially fixed in the two iron-wood discs 20, and the plurality of cylindrical bars 10 are arranged in a circular shape.

[0022] One of the barrel bars 10 is set, one end of the barrel bar 10 is vertically fixed in the milling groove of one of the iron wood discs 20, and the other end of the barrel bar 10 is vertically fixed on the other disc. inside the milling slot.

[0023] The cylinder bar of the present invention is vertically fixed in the milling groove of the iron wood disc 20, which can increase the fan plate strength of the iron wood disc 20, prevent falling and falling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com