Magnetic separation mechanism and using method thereof

A magnetic separation and magnetic technology, applied in used abrasive processing devices, abrasives, metal processing equipment, etc., can solve problems such as affecting the accuracy of flow control valves, inability to meet equipment, and unstable shot peening (sand) results. Achieve excellent application prospects and market value, simple structure, and avoid instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

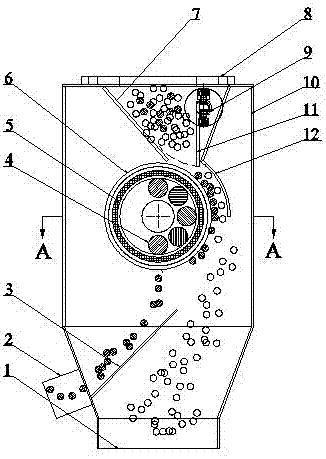

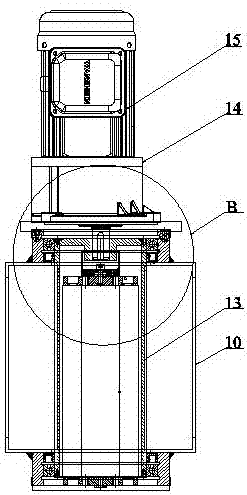

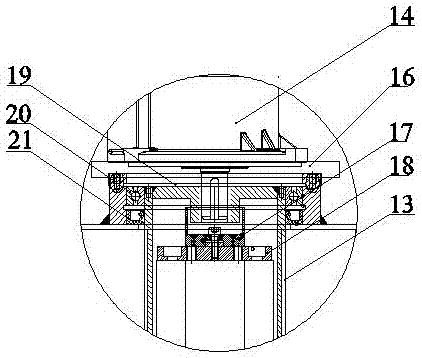

[0029] refer to Figure 1 to Figure 6 , a magnetic separation mechanism, including a magnetic separation chamber 10, a rotor separation assembly 6 disposed in the magnetic separation chamber 10, and a drive assembly for driving the rotor separation assembly 6 to rotate, and the rotor separation assembly 6 utilizes its internal design The magnetism of some magnetic adsorption components 5 absorbs and separates the magnetic substances entering the tiles in the magnetic separation chamber 10 during the rotation process.

[0030] A V-shaped hopper 7 is arranged inside the inlet of the magnetic separation chamber 10 , and the outlet of the V-shaped hopper 7 is close to the rotor separation assembly 6 and located above the magnetic side of the rotor separation assembly 6 .

[0031] The discharge port of the V-shaped hopper 7 is provided with an arc-shaped deflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com