3D printing device for rope traction parallel mechanism

A technology of 3D printing and printing devices, applied in the direction of processing drive devices, additive processing, etc., to achieve the effects of wide practicability, easy disassembly and assembly, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

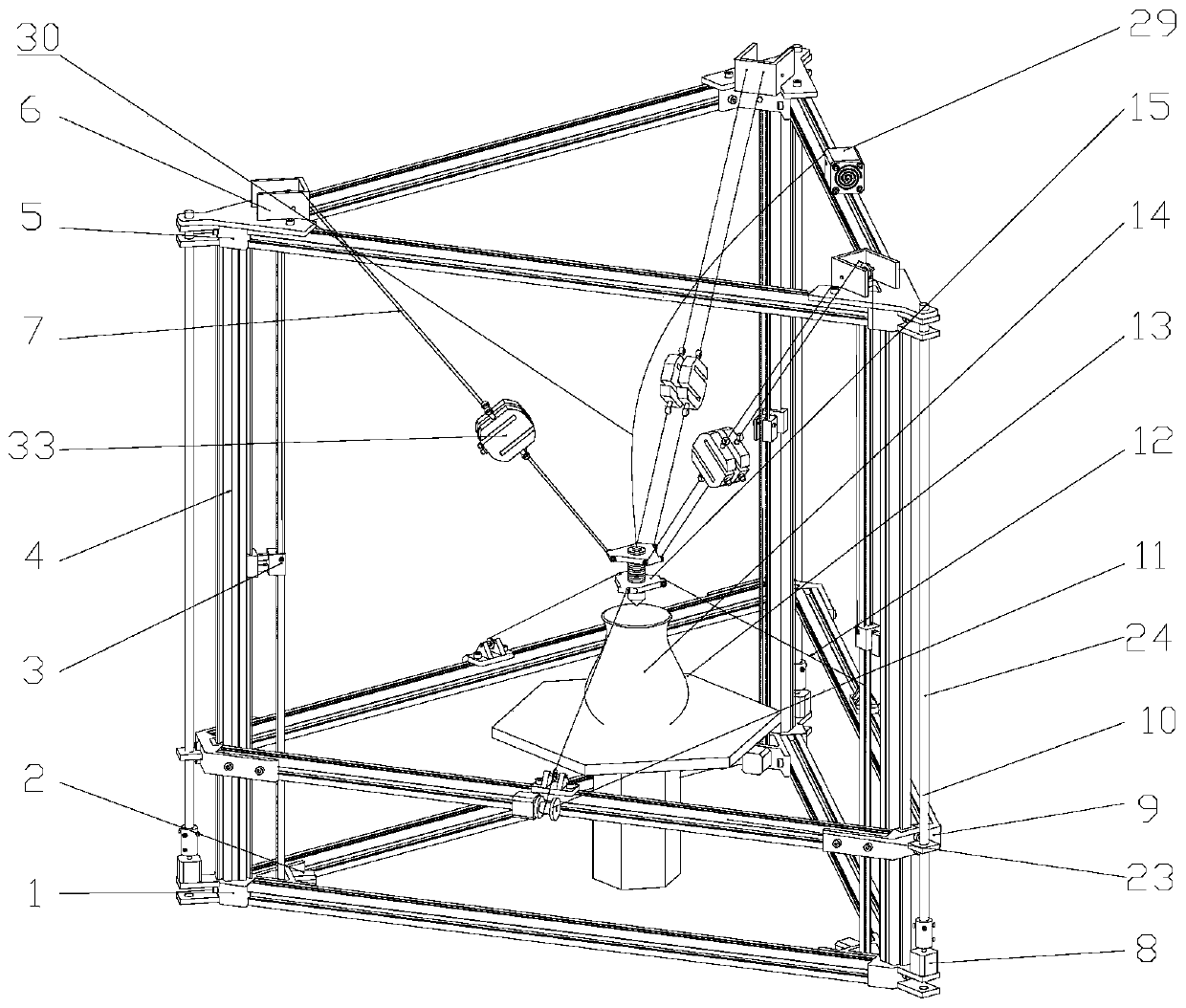

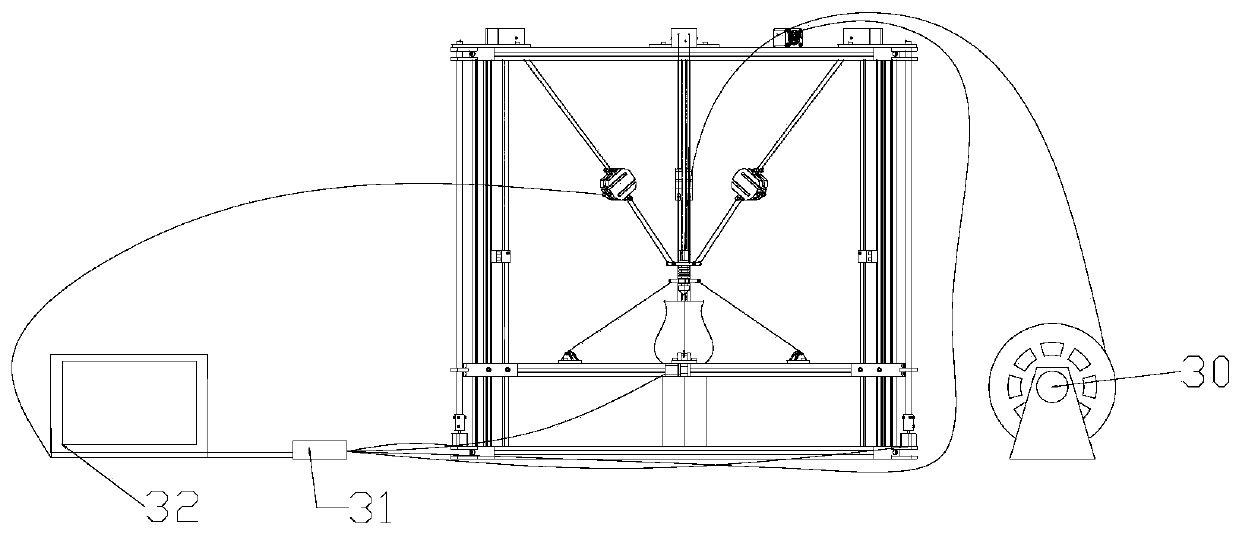

[0021] Such as Figure 1-Figure 6 As shown, the rope traction parallel mechanism 3D printing device includes a bracket, a traction mechanism, an auxiliary adjustment mechanism, and a consumable motor 29, wherein:

[0022] The support includes a lower support frame 1 of an equilateral triangle, and an upper beam frame 5 of the same equilateral triangle is arranged above the lower support frame 1, and a vertical support rod 4 is vertically connected between the triangular positions of the lower support frame 1 and the upper beam frame 5 respectively. , a printing device 15 is provided in the space surrounded by the lower support frame 1, the upper beam frame 5, and the vertical support rod 4;

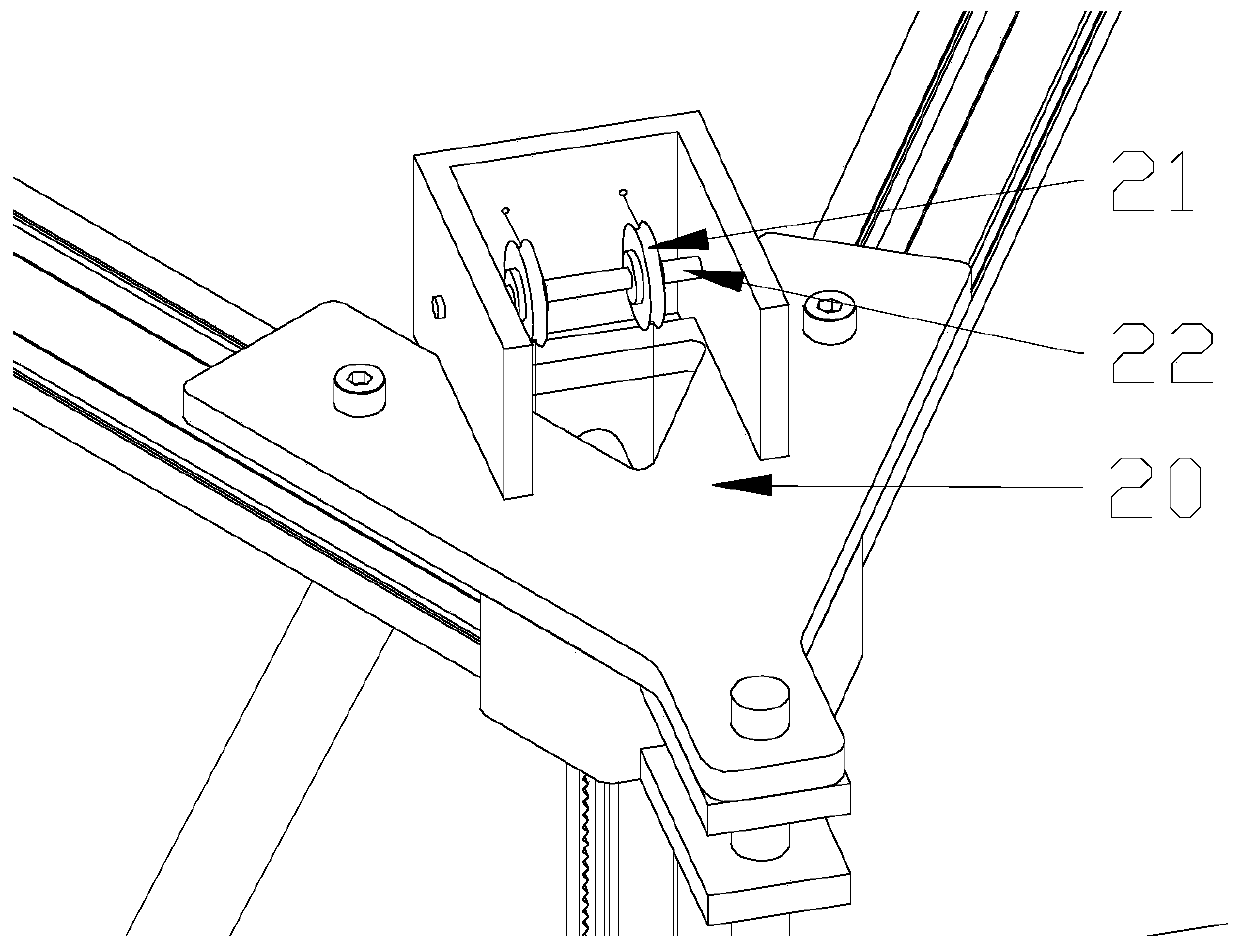

[0023] The traction mechanism includes a conveyor belt motor 2 installed near the lower end of each vertical support bar 4, a guide pulley mechanism 6 installed near the upper end of each vertical support bar 4, a Pulley transmission mechanism 3, pulley transmission mechanism 3 comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com