Full-automatic PVC powder concentrated negative pressure material supplying system

A feeding system, fully automatic technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of no traceability of the production process, on-site environmental pollution, high labor intensity of workers, and solve the problems of high labor intensity of workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

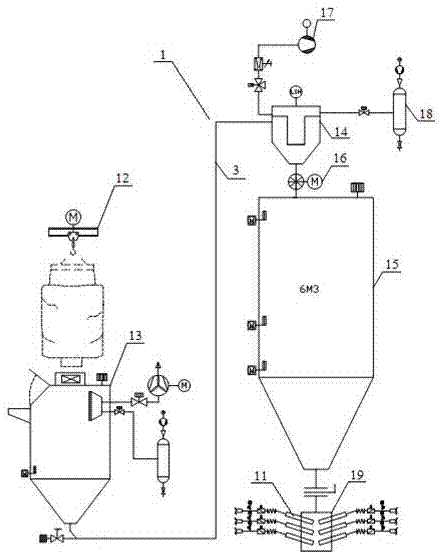

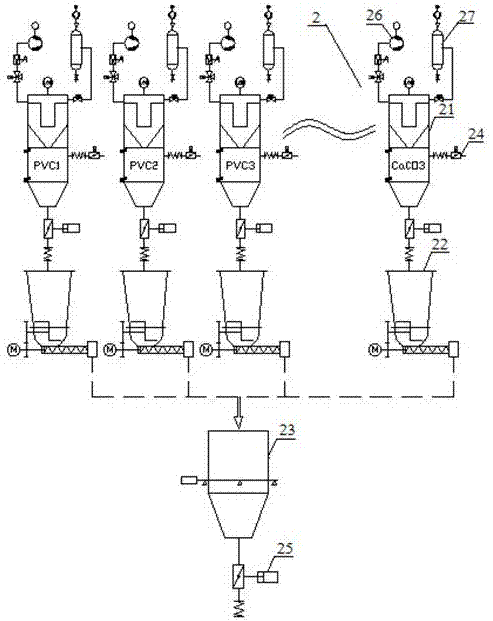

[0025] Such as Figure 1 to Figure 2 Shown is the first embodiment of the automatic PVC powder centralized negative pressure feeding system of the present invention, including several high-mixers arranged on the extrusion production line and controllers for controlling the amount of PVC powder supplied; It also includes a centralized storage device 1 and several automatic distribution devices 2 that deliver PVC powder to the high mixer under the action of vacuum negative pressure. Connection; the bottom of the centralized material storage device 1 is provided with several feeding devices 11 for conveying PVC powder to the automatic material distribution device 2 under the action of vacuum negative pressure; the centralized material storage device 1 and the automatic material distribution device 2 are connected with the controller connect.

[0026] Among them, such as figure 1 As shown, the centralized material storage device 1 includes a row crane 12, a feeding station 13, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com