Movable-type cold in-plant recycling machine

A cold mixing and recycling machine, mobile technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of hindering the recycling rate of old materials on road pavement, time-consuming and labor-intensive migration, and low production efficiency, so as to achieve convenient and flexible transition. Effect of compact structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

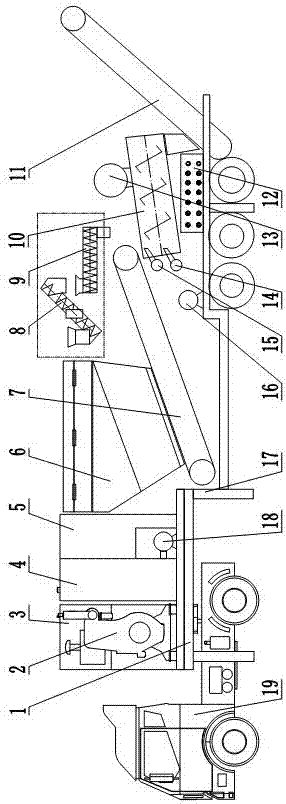

[0022] Embodiments of the present invention are described below in conjunction with the accompanying drawings, including a tractor 19, a vehicle frame 1, a power unit 2, a hydraulic system 3, an ingredient conveying device and a stirring device 10. The power unit 2, the water tank 4 and the fuel tank 5 are arranged at the front end of the vehicle frame 1.

[0023] Aggregate conveying device 7, stirring device 10 and unloading belt conveyor 11 are sequentially arranged on the vehicle frame 1; the discharge end of aggregate conveying device 7 is located at the receiving port of stirring device 10; Above the end, there is a silo 6;

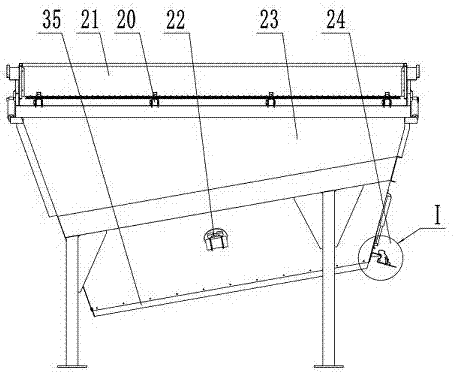

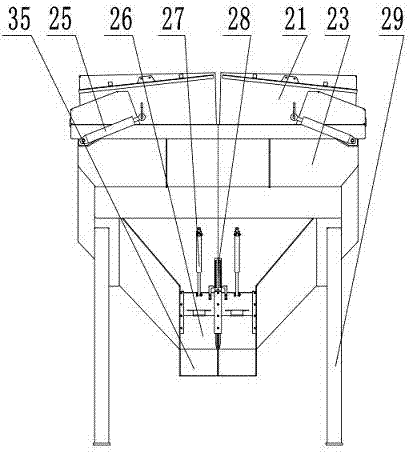

[0024] The silo 6 is installed on the vehicle frame 1 through the legs 29. The silo body 23 is divided into two silos, a regenerated silo and a new aggregate silo, and each silo is equipped with a foldable hinge 20 on the top of each silo. The silo screen 21 net, the silo screen 21 is connected with the silo body 23 through the overturning cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com