Construction method of longitudinal moving tied-arch bridge

A tie-bar arch bridge and construction method technology, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of being unable to accommodate large-scale hoisting machinery and equipment, and achieve the effect of strong rigidity, not easy to deform, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

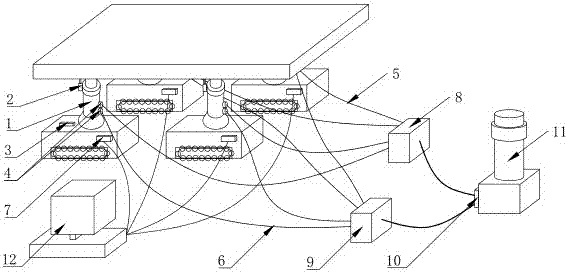

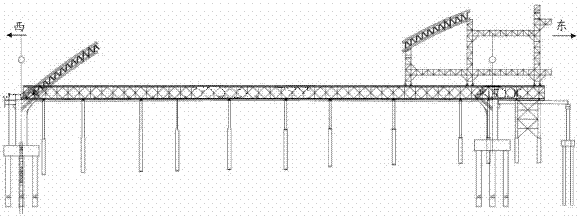

[0038] like figure 1 , figure 2 As shown, the construction method of longitudinally moving tie-bar arch bridge, with the help of longitudinally moving track, dragging device, anti-rollover device and three-dimensional fine-tuning system erected on the site, the arch ribs and cross braces assembled outside the site are moved longitudinally to the design position The construction method first sets up the longitudinal moving track structure, installs the overall longitudinal moving device of the tie-bar arch bridge, and at the same time assembles part of the arch ribs of the tie-bar arch bridge. Arch rib concrete, and finally remove the auxiliary device for longitudinal movement; the specific steps include the following:

[0039] Step S1: Set up temporary support piers for moving beams and build steel truss beams for longitudinal moving tracks to complete the construction of longitudinal moving tracks;

[0040] Step S2: install a plurality of weight shifters on the longitudina...

Embodiment 2

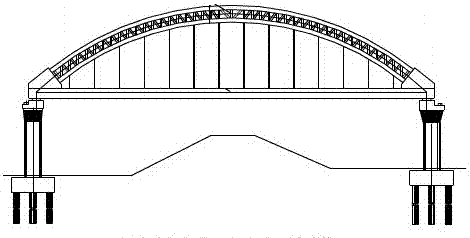

[0047] This embodiment takes the construction of an inner arch bridge in a railway station in Hunan as an example, and further optimizes it on the basis of the above embodiments. In this embodiment, the main bridge adopts a rigid frame concrete-filled steel pipe tied arch bridge with L=168m. The main bridge is 172 m long and 24 m wide. The longitudinal axis of the bridge and the railway cross 17 lanes at the railway hub station at an oblique angle of 29°. The main line is the main line of the electrified railway, with high traffic frequency and high shunting frequency of passenger and freight trains. There are many above-ground and underground pipelines on both sides of the station, and the construction site under the bridge is basically occupied by the traffic limit, which makes the project more difficult and technical. Due to the large-scale electrified railway station, the conventional cable crane segmental hoisting scheme cannot be implemented; the implementation method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com