Building decoration equipment with ceramic tile seam beautifying automatic treatment function

An automatic processing and architectural decoration technology, applied in the direction of architecture and building structure, can solve problems such as easy omissions, hidden dangers of staff safety, and high labor intensity, so as to ensure personnel safety, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

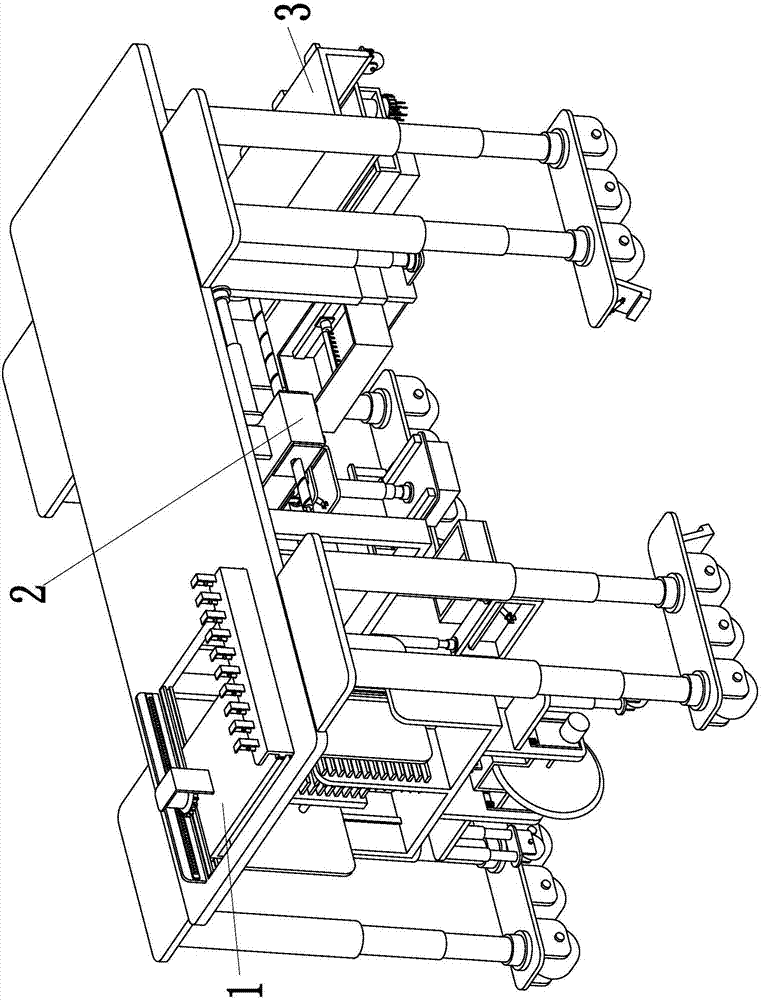

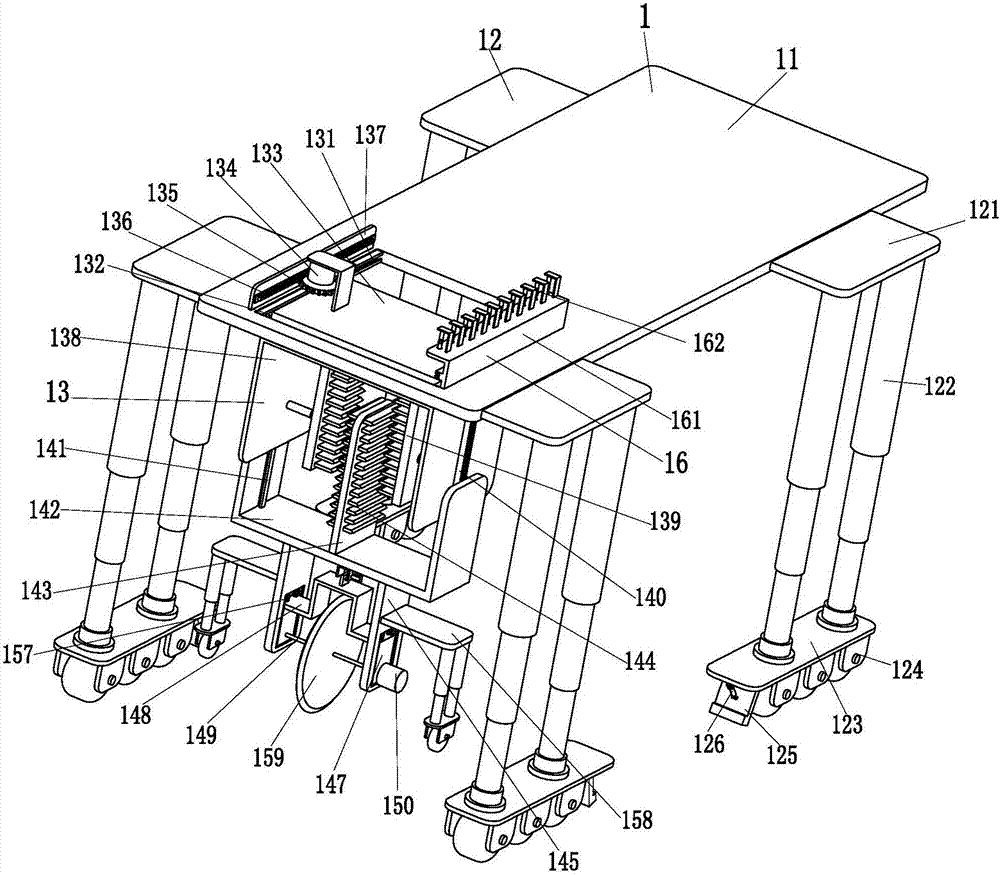

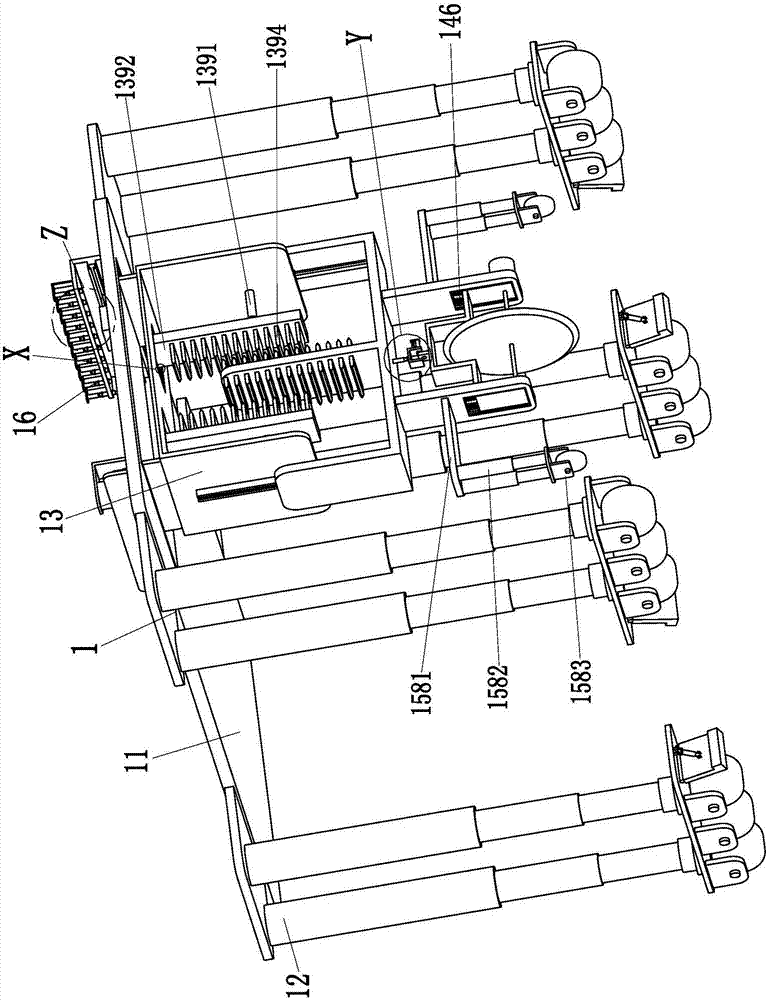

[0040] like Figure 1 to Figure 11 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a building decoration equipment that can automatically process ceramic tiles, including a cutting device 1, a cleaning device 2 and a drying device 3, a pair of cutting devices 1 Grooves are cut at the seams of the tiles, the cleaning device 2 cleans the ground, and the drying device 3 dries the ground. Drying device 3 is installed.

[0041] The slitting device 1 includes a support plate 11, four moving mechanisms 12, a slitting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com