Hydraulic multi-end output transfer case

A transfer case, multi-head technology, applied in transmission parts, fluid drive clutches, non-mechanical drive clutches, etc., to meet the requirements of special devices, easy to operate, and reasonable in structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

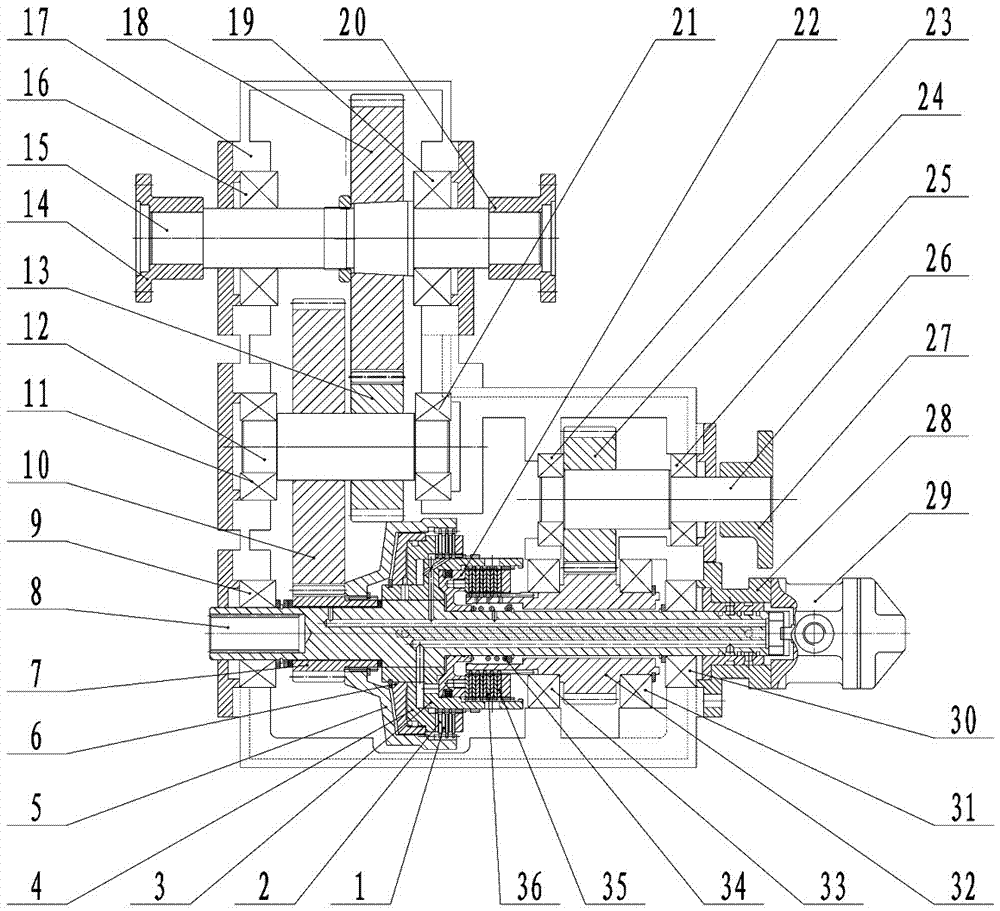

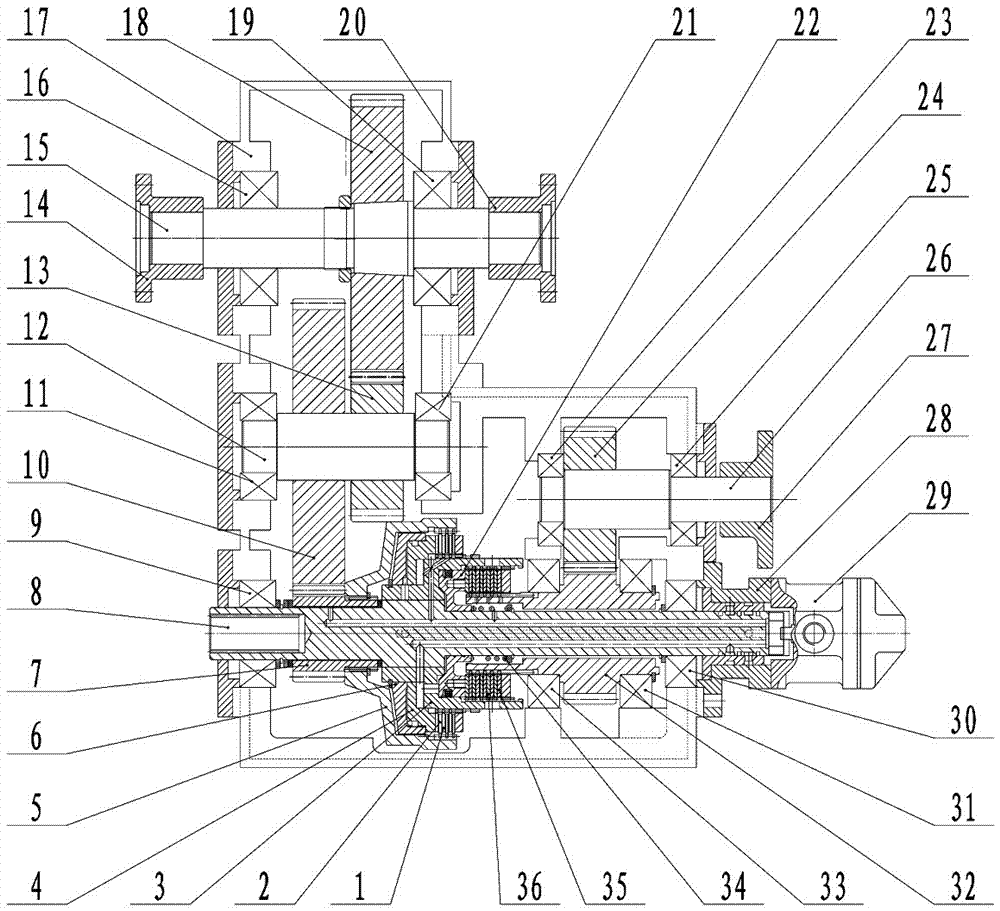

[0019] Reference figure 1 As shown, the transfer case of the present invention has an input shaft 8 with an inner clutch seat 3 fixed on the input shaft, and a large piston 4, an oil cylinder 6, and a large clutch housing 5 are sleeved on the inner clutch seat.

[0020] The input shaft 8 is also fitted with a driving gear 7, and the input shaft 8 is also fitted with a small piston 22, a return spring 34, a water driving gear 32 and bearings 9 and 30.

[0021] After the motor shaft is connected with the transfer case input shaft 8, the input shaft 8 rotates, because the inner clutch seat is fixed on the input shaft 8. When the large piston sleeved on the inner clutch seat moves, the inner friction plate 1 and The outer friction plate 2 rotates the large clutch housing 5 at the same time. One end of the large clutch housing is connected with the driving gear by splines to rotate the driving gear 7 and the driving gear 7 drives the first slave tooth 10 to rotate. The intermediate mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com