Neutron activation analysis device

A technology of activation analysis and equipment, applied in the field of cement production raw material testing equipment, can solve problems such as deviations and restrictions on the development of the cement production industry, to solve adjustment lag, improve sampling efficiency and accuracy, reduce labor intensity and safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

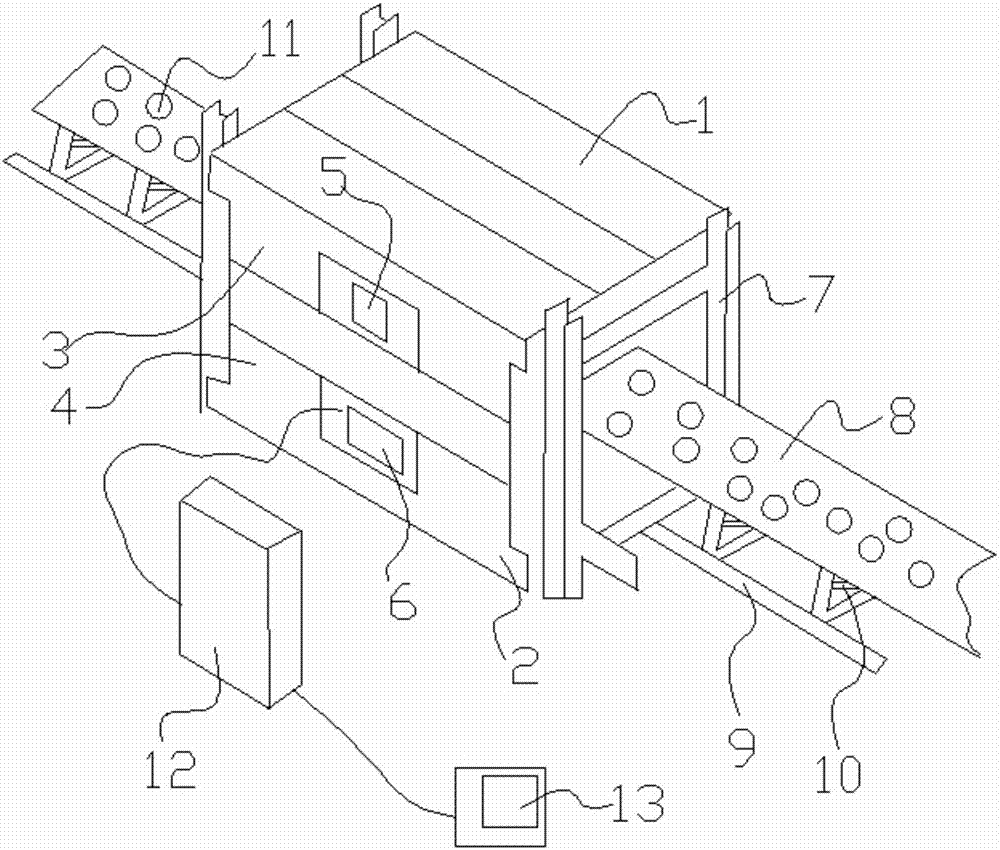

[0018] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. detailed instructions.

[0019] Such as figure 1 As shown, the neutron activation analysis equipment includes a shielding assembly, a radioactive source and a detector, the shielding assembly is fixed on the shielding assembly bracket 7, the radioactive sources are evenly distributed in the radioactive source cavity 3, and the detector is arranged in the detector cavity 4, the radioactive source cavity 3 is located on the upper part of the detector cavity 4, and a through cavity is set between the radioactive source cavity 3 and the detector cavity 4, and the conveyor belt 8 carries the coal raw material 11 through the cavity, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com