Gas turbine lubricating oil system metal shavings online monitoring system

A monitoring system and metal shavings technology, applied in radio wave measurement systems, measuring devices, geophysical measurements, etc., can solve the problems of hidden troubles in the lubricating oil system and the inability to realize real-time online monitoring of the size and quantity of metal shavings, and achieve safety The effects of reliable use, avoidance of representation and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

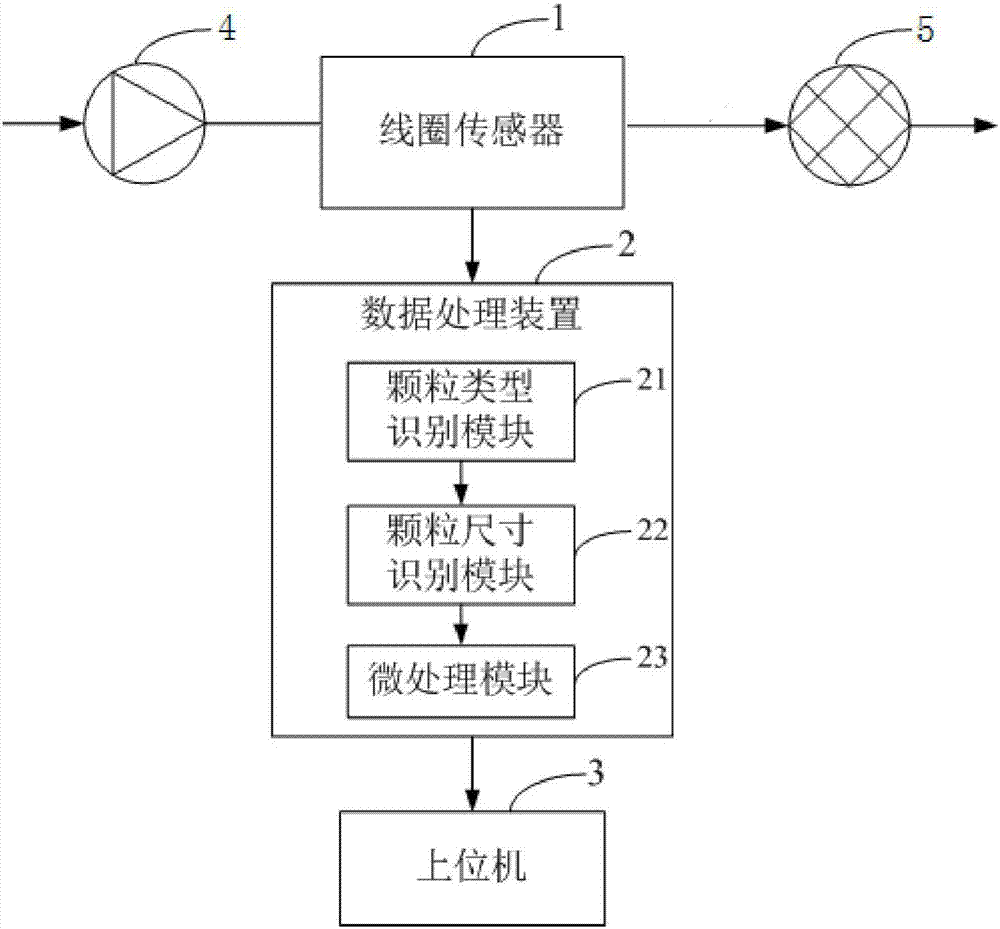

[0016] This invention designs an on-line monitoring system for metal scraps in the lubricating oil system of a gas turbine. The design idea is to install the coil sensor on the total oil return pipeline from the lubricating oil booster pump to the lubricating oil filter of the gas turbine, and there are corresponding sealing measures. Change the original oil circuit.

[0017] The working principle of the coil sensor 1 in the online monitoring system of metal scraps in the lubricating oil system: when the engine is working, due to the interaction of mechanical friction pairs, many metal particles will be produced. Under the action of the lubrication system, these particles will be suspended in the lubricating oil. According to the concentration of metal particles in lubricating oil, the severity of wear can be judged from the size distribution of wear particles, the concentration of particles and their changing trends. By analyzing the debris in the oil, it is possible to monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com