Wide-angle-incidence infrared cutoff optical filter without half-wave hole and membrane system design method thereof

A technology of infrared cut-off and half-wave holes, applied in optics, optical components, instruments, etc., can solve problems such as the decrease of transmittance in the wavelength region and the appearance of half-wave holes, and achieve full and bright colors, more colors, and true imaging colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

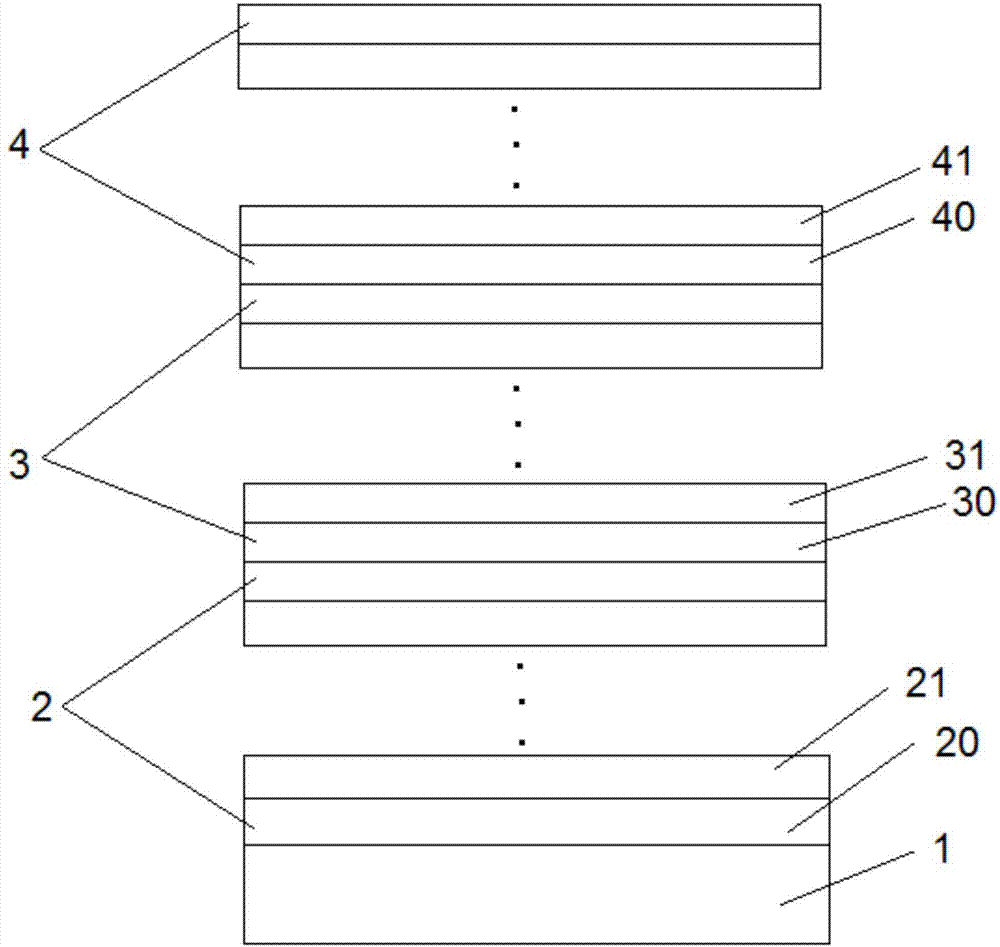

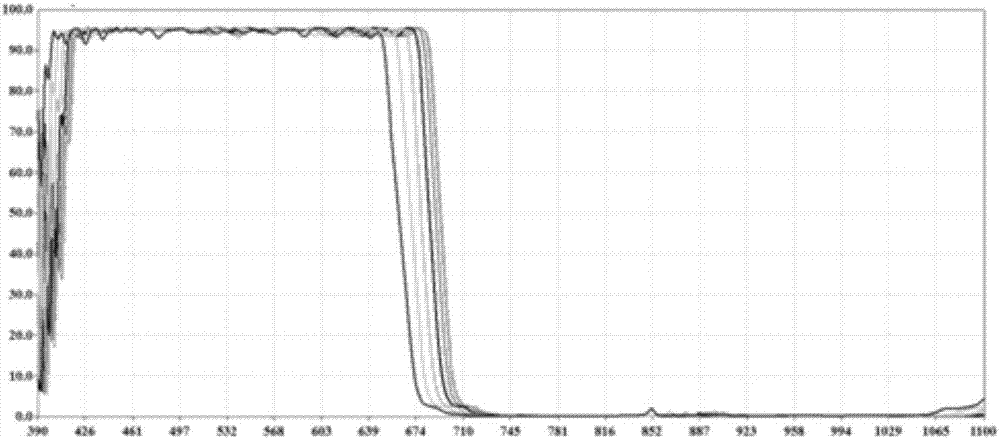

[0037] Infrared-absorbing glass with a thickness of 0.21mm is used as the substrate, and a layer of TiO made of high refractive index material is provided on the front of the substrate. 2 and low refractive index material film layer SiO 2 Alternately stacked infrared cut-off films, on the back of the substrate are provided with an optical thickness of λ 0 / 4 TiO 2 layer and SiO 2 Anti-reflective coating (AR) composed of layers. Among them, the high refractive index material film layer TiO 2 The refractive index of 2.354, low refractive index film SiO 2 The refractive index is 1.46, and the optical thickness coefficient of the infrared cut-off film system is designed as:

[0038] 0.225H 0.470L 2.398H 2.317L 2.399H 2.460L 2.453H 2.443L 2.477H 2.465L2.454H 2.448L 2.434H 2.401L 2.367H 2.318L 2.276H 2.247L 2.221I 2.190M 2.113I2.143M 2.252I 2.245M 2.191I 2.196M 2.183I 2.191M 2.118I 2.096M 1.984I 2.006M1.909I 1.936M 1.86I 1.888M 1.926J 1.921N 1.88J 1.887N 1.754J 1.885N 1.672J...

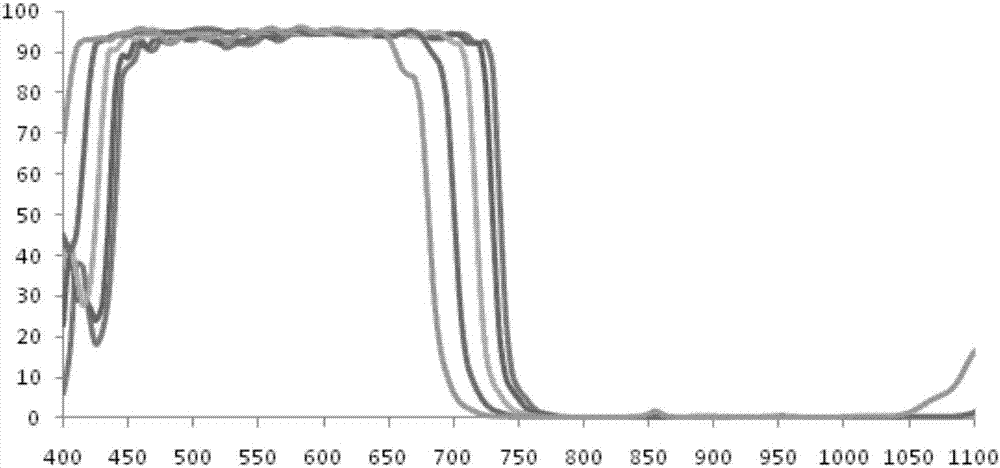

Embodiment 2

[0042] Infrared-absorbing glass with a thickness of 0.21mm is used as the substrate, and a layer of TiO made of high refractive index material is provided on the front of the substrate. 2 and low refractive index material film layer SiO 2 Alternately stacked infrared cut-off films, on the back of the substrate are provided with an optical thickness of λ 0 / 4 TiO 2 layer and SiO 2 Anti-reflective coating (AR) composed of layers. Among them, the high refractive index material film layer TiO 2 The refractive index of 2.354, low refractive index film SiO 2 The refractive index is 1.46, and the optical thickness coefficient of the infrared cut-off film system is designed as:

[0043] 0.212H 0.474L 2.492H 2.493L 2.608H 2.616L 2.604H 2.583L 2.594H 2.589L2.556H 2.532L 2.487H 2.475L 2.420H 2.440L 2.430H 2.424L 2.340I 2.305M 2.303I2.366M 2.382I 2.369M 2.304I 2.313M 2.315I 2.325M 2.234I 2.162M 2.053I 2.063M2.064I 2.086M 1.964I 2.063M 2.091I 2.043M 1.942J 1.988N 1.830J 1.968N 1.760J...

Embodiment 3

[0047] Infrared-absorbing glass with a thickness of 0.21mm is used as the substrate, and a layer of TiO made of high refractive index material is provided on the front of the substrate. 2 and low refractive index material film layer SiO 2 Alternately stacked infrared cut-off films, on the back of the substrate are provided with an optical thickness of λ 0 / 4 TiO 2 layer and SiO 2 Anti-reflective coating (AR) composed of layers. Among them, the high refractive index material film layer TiO 2 The refractive index of 2.354, low refractive index film SiO 2 The refractive index is 1.46, and the optical thickness coefficient of the infrared cut-off film system is designed as:

[0048] 0.201H 0.449L 2.360H 2.361L 2.471H 2.478L 2.467H 2.456L 2.457H 2.452L2.421H 2.398L 2.356H 2.344L 2.293H 2.311L 2.301H 2.296L 2.216I 2.204M 2.182I2.202M 2.256I 2.244M 2.183I 2.191M 2.153I 2.142M 2.116I 2.108M 2.045I 2.035M1.956I 1.946M 1.860I 1.855M 1.981J 1.935N 1.840J 1.883N 1.733J 1.864N 1.667J...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Physical thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com