Preparation method of red pepper skin powder printing paste

A technology for printing color paste and red pepper, applied in the field of textile printing and dyeing, can solve the problems of slight irritation and microtoxicity, irritation of mucous membranes and respiratory tract, acetone is easy to burn and explode, etc., and achieves good printing fastness, sufficient dispersion, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Mix the red pepper skin powder with a particle size of 100nm, the binder UDT, and the thickener at a ratio of 7%, 92.5%, and 0.5% by mass percentage, and mix them under the condition that the ambient temperature is 27°C. First stir in the mixer at a speed of 180r / min for 22min, stir it evenly, then stir at a speed of 850r / min for 55min, let stand, and form a printing paste.

Embodiment 2

[0013] Mix the red pepper skin powder with a particle size of 150nm, the binder UDT, and the thickener at a ratio of 9%, 90%, and 1% by mass percentage, and mix them under the condition that the ambient temperature is 28°C. Stir in the mixer at a speed of 230r / min for 17min, stir it evenly, then stir at a speed of 950r / min for 45min, let it stand, and form a printing paste.

Embodiment 3

[0015] Mix the red pepper peel powder with a particle size of 200nm, the binder UDT, and the thickener at a ratio of 11%, 87%, and 2% by mass percentage, and mix them under the condition that the ambient temperature is 29°C. First stir in the mixer at a speed of 280r / min for 12min, then stir it evenly, then stir at a speed of 1050r / min for 35min, and let it stand to form a printing paste.

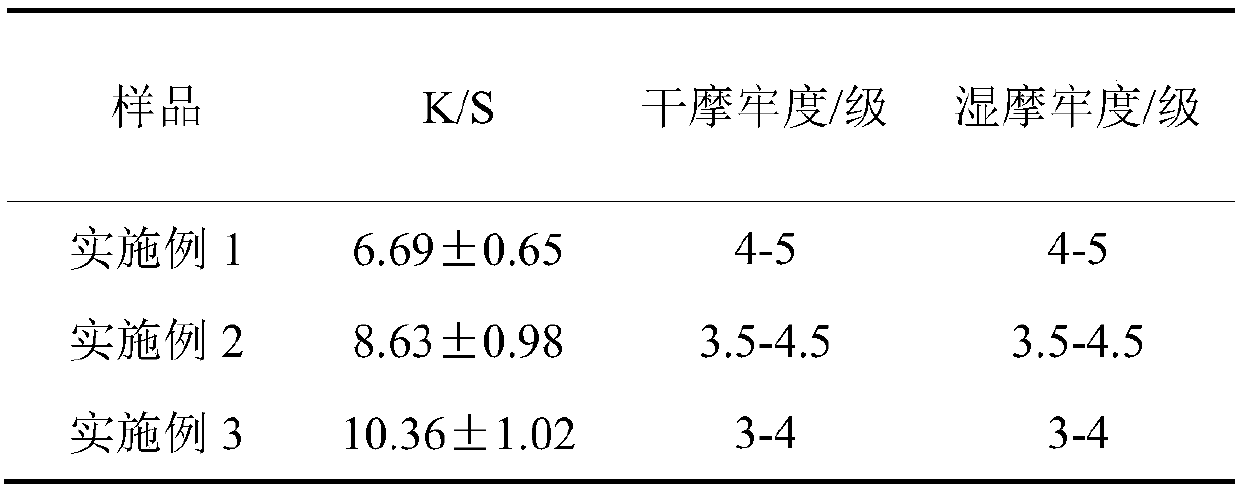

[0016] Table 1 Apparent depth and fastness of printed fabrics

[0017]

[0018] As can be seen from Table 1, using colored red pepper peel powder instead of synthetic pigments can give printed fabrics full color without any pollution to the environment. With the increase of the mass percentage of red pepper peel powder in the printing paste, the apparent depth of the printed fabric gradually increases, and the dry and wet rubbing fastness are good, both above grade 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com