Flavor walnut milk and preparation method thereof

A technology for walnut milk and flavor, applied in the food field, can solve the problems of indigestion and absorption of nutrients, unsatisfactory taste, and greasy walnut kernels, etc., and achieve the effects of enriching taste, brightening color and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of flavored walnut milk, comprising the following contents:

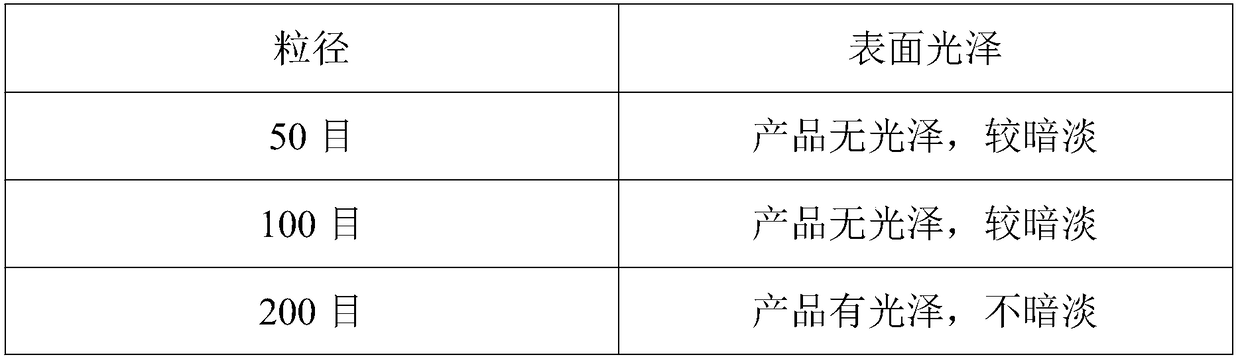

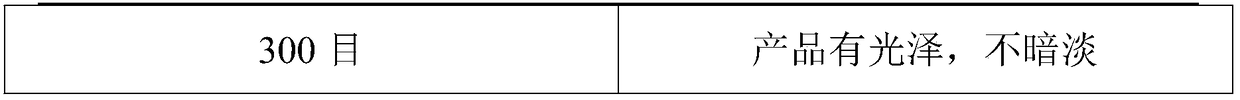

[0036] (1) Take 60 parts of walnut powder, 4 parts of peanut powder, 0.5 part of garlic, and 0.5 part of bay leaf, add water that is 6 times its mass, let it stand for 1 hour, and then pass through a colloid mill to obtain walnut primary emulsion, and make the prepared walnut The particle size of the primary emulsion is less than 200 mesh; pour the walnut primary emulsion with a particle size of less than 200 mesh into a homogenizer for homogenization. When homogenizing, the temperature of the walnut primary emulsion is 50°C, and the pressure is set to 25Mpa;

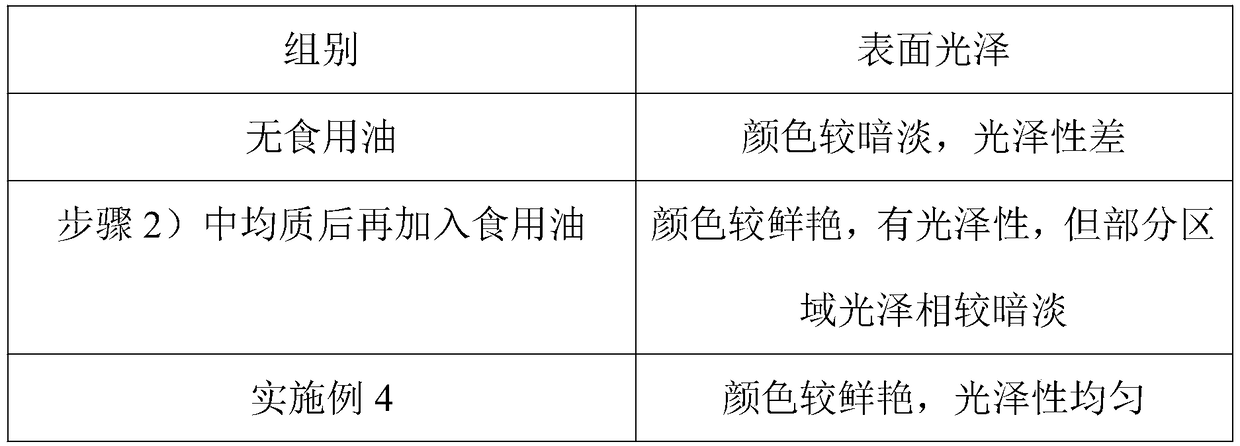

[0037] (2) Take 4 parts of beet juice, 3 parts of edible gum, 4 parts of lotus root starch, 0.5 part of mustard, 0.1 part of vegetable oil and mix with walnut primary emulsion, homogenize to obtain walnut milk, wherein control the mixed walnut primary emulsion before homogenization The temperature is above 90°C, and the pressure in...

Embodiment 2

[0040] A preparation method of flavored walnut milk, comprising the following contents:

[0041] (1) Take 65 parts of walnut powder, 5 parts of peanut powder, 2 parts of garlic, and 0.5 part of fragrant leaves, add water that is 8 times its mass, let it stand for 3 hours, and then pass through a colloid mill to obtain walnut primary emulsion, and make the prepared walnut The particle size of the primary emulsion is less than 200 mesh; pour the walnut primary emulsion with a particle size of less than 200 mesh into a homogenizer for homogenization. When homogenizing, the temperature of the walnut primary emulsion is 50°C, and the pressure is set to 25Mpa;

[0042] (2) Take 5 parts of beet juice, 5 parts of edible gum, 5 parts of lotus root, 0.6 part of mustard, 0.3 part of vegetable oil and mix with walnut primary emulsion, homogenize to obtain walnut milk, wherein control the mixed walnut primary emulsion before homogenization The temperature is above 90°C, and the pressure in...

Embodiment 3

[0045] A preparation method of flavored walnut milk, comprising the following contents:

[0046] (1) Take 75 parts of walnut powder, 7 parts of peanut powder, 2 parts of garlic, and 0.8 part of fragrant leaves, add water that is 8 times its mass, let it stand for 4 hours, and then pass through a colloid mill to obtain walnut primary emulsion, and make the prepared walnut The particle size of the primary emulsion is less than 200 mesh; the walnut primary emulsion with a particle size of less than 200 mesh is poured into a homogenizer for homogenization, the temperature of the walnut primary emulsion is 55°C during homogenization, and the pressure is set to 25Mpa;

[0047] (2) Take 6 parts of beet juice, 5 parts of edible gum, 5 parts of lotus root powder, 0.5 part of mustard, 0.3 part of vegetable oil and mix with walnut primary emulsion, homogenize to obtain walnut milk, wherein control the mixed walnut primary emulsion before homogenization The temperature is above 90°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com