Integrated circuit layout division method and system for multiple photolithography

An integrated circuit and layout technology, applied in electrical digital data processing, instruments, calculations, etc., can solve the problems of long calculation time and low efficiency of photolithography, and achieve the effect of improving coloring efficiency, improving quality, and improving dividing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

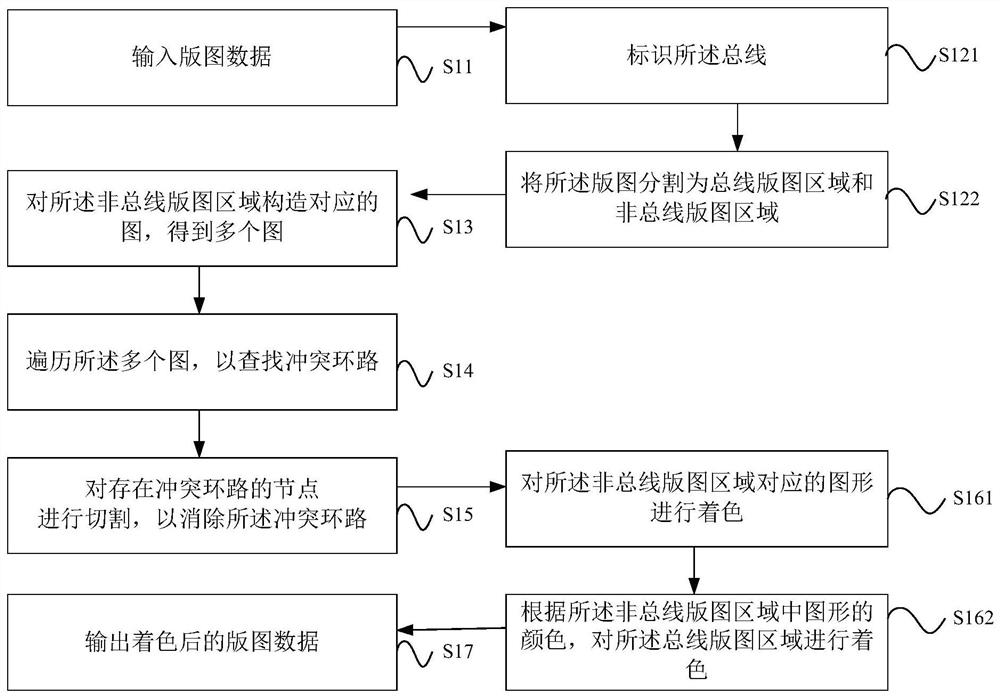

[0063] See image 3 as well as Figure 4A-Figure 4J ,in image 3 It is a flow chart of a layout division method including a bus for the layout type; Figure 4A-Figure 4J A schematic diagram corresponding to each step of layout including a bus.

[0064] Layout types include bus layout methods include:

[0065] Step S11: input layout data;

[0066] Such as Figure 4A As shown, it is the layout data including the bus; the layout includes the bus A1, and the bus is located on both sides of the cell layout.

[0067] Step S121: Identify the bus;

[0068] Step S122: Divide the layout into a bus layout area and a non-bus layout area.

[0069] Such as Figure 4B As shown, it is a schematic diagram of the steps after identifying the bus A1 and dividing the layout.

[0070] Step S13: Construct corresponding graphs for the non-bus layout area to obtain multiple graphs.

[0071] Such as Figure 4C As shown, it is a graph constructed according to the non-bus layout area after the...

Embodiment 2

[0088] See Figure 5 as well as Figure 6A-6F ,in Figure 5 It is a flow chart of a layout division method including a long signal line for the layout type; Figure 6A-6F A schematic diagram corresponding to each step of layout division for a layout including long signal lines.

[0089] The layout type includes layout division methods including long signal lines, including:

[0090] Step S21: input layout data;

[0091] Such as Figure 6A As shown, it is the layout data including the long signal line; the layout includes the long signal line B1, the long signal line is a long signal line whose length is several times the unit height, and the plane distance between the long signal line and other graphics is generally less than The minimum distance between graphics on the same process layer.

[0092] Step S221: Identify the long signal line;

[0093] Step S222: dividing the layout of the part other than the long signal line into a plurality of non-long signal line layout ...

Embodiment 3

[0108]Please refer to the steps in the second embodiment, the difference is that the layout type in this embodiment is a layout including complex polygons. Dividing the layout into a plurality of layout areas according to the layout type specifically includes: adaptively calculating a graphics cutting work window, and dividing the layout into a plurality of work windows, each of which is a layout area. Afterwards, a map is constructed for each layout area, traversing conflict loops, eliminating conflict loops, and coloring, and finally outputs the colored layout data. Since the division of layout data into multiple working windows in this embodiment is essentially the same as the division of long signal lines, therefore, no detailed description is given in this example, and the same parts refer to Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com