Method for installing magnetic steel in circular hole

A magnetic steel and round hole technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as rework difficulties, assembly difficulties, and magnetic steel scrapping, so as to overcome magnetic effects and reduce assembly rework The effect of efficiency and saving assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

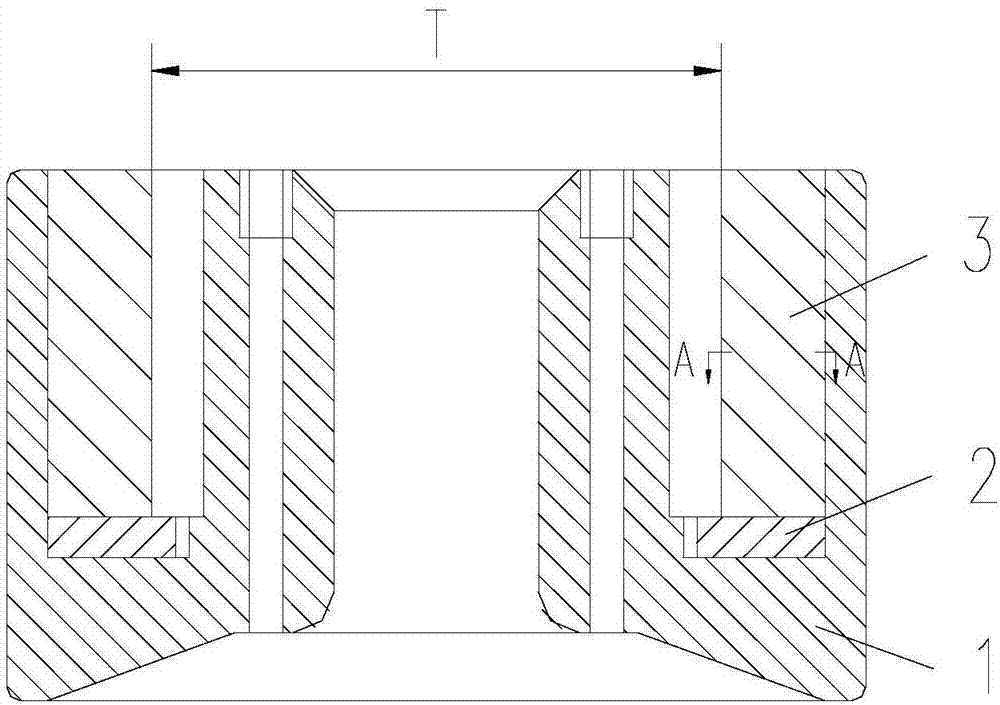

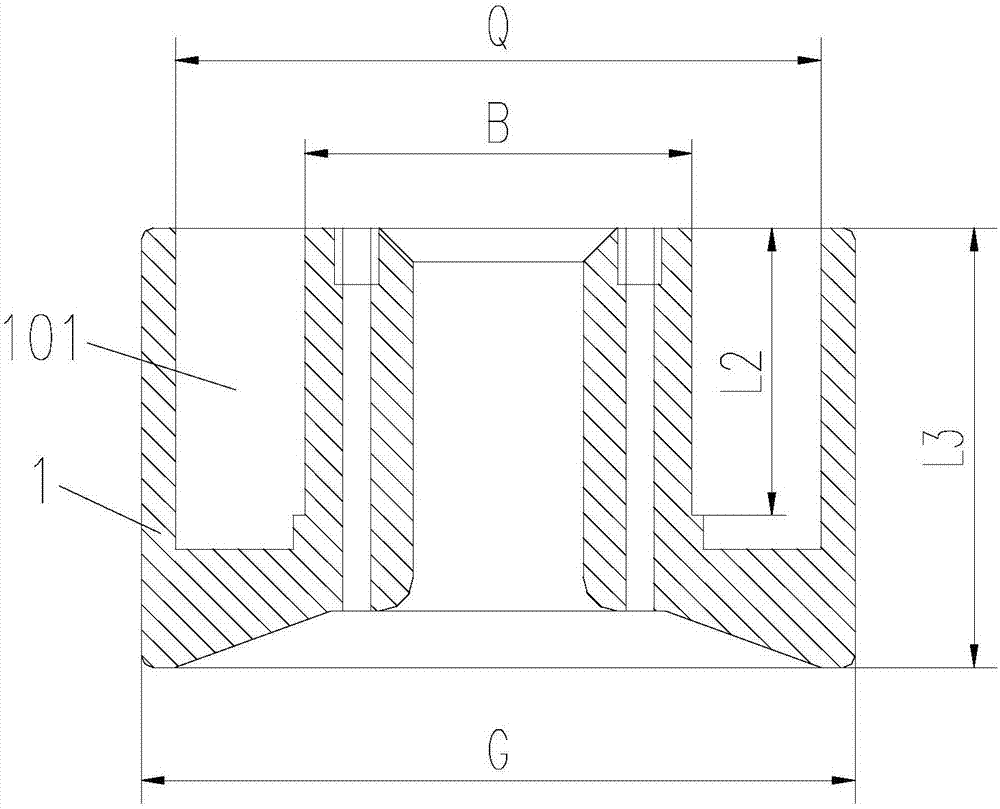

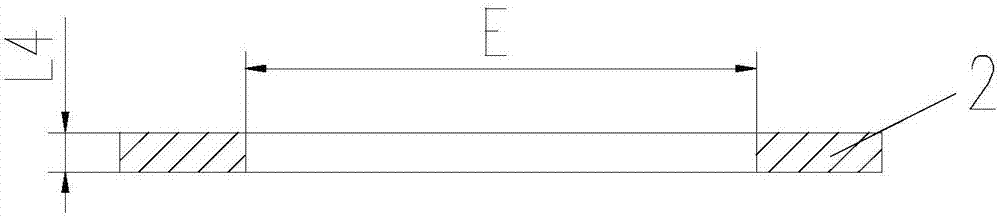

[0049] Attached below Figure 1-22 Embodiments of the present invention are described.

[0050] The method for installing the magnetic steel in the circular hole includes the following installation steps:

[0051] Step 1: Install the yoke body 1 into the fixture base 4 for fixing, such as Figure 12 shown;

[0052] Specifically, such as Figure 5 and 2 As shown, the center of the clamp base 4 is formed with a hole I401 adapted to fit into the yoke body 1, and the difference between the dimensions L7 and L6 in the height direction of the hole I401 is smaller than the height L3 of the yoke body 1; The cylindrical surface with a diameter G of the body 1 is in clearance fit with the cylindrical surface with a diameter F in the hole I401 of the clamp base 4 with a clearance greater than 0.01 mm.

[0053] Step 2: Install the auxiliary magnetic steel 2 on the bottom of the auxiliary magnetic steel installation fixture 5, then insert the auxiliary magnetic steel installation fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com