Five-axis linkage laser cutting machine and cutting process thereof

A laser cutting machine, five-axis linkage technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to cut three-dimensional planes of flexible products, inability to three-dimensional plane processing, small degrees of freedom and other problems, to overcome The effect of high product rigidity and hardness requirements, high degree of automation, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

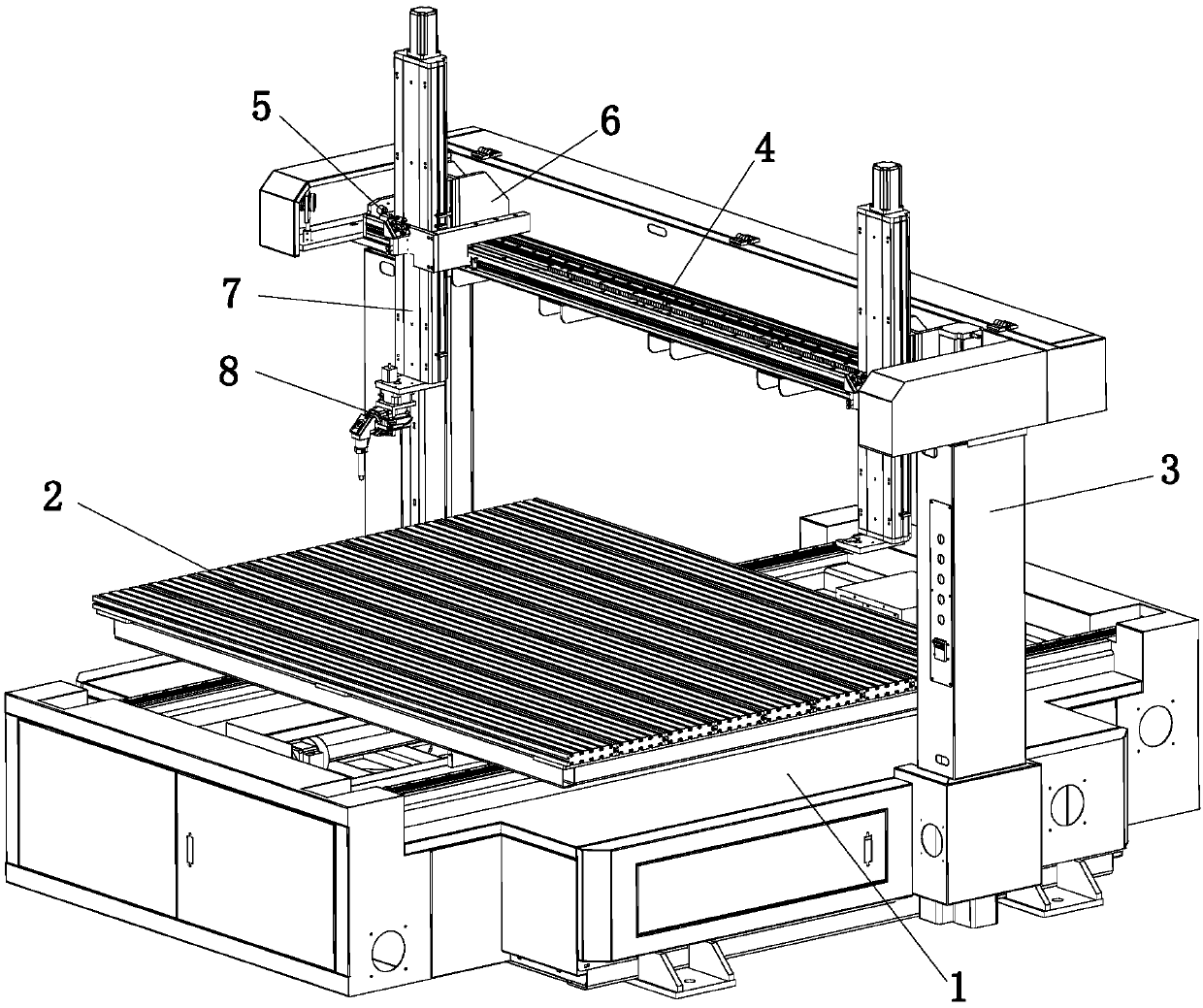

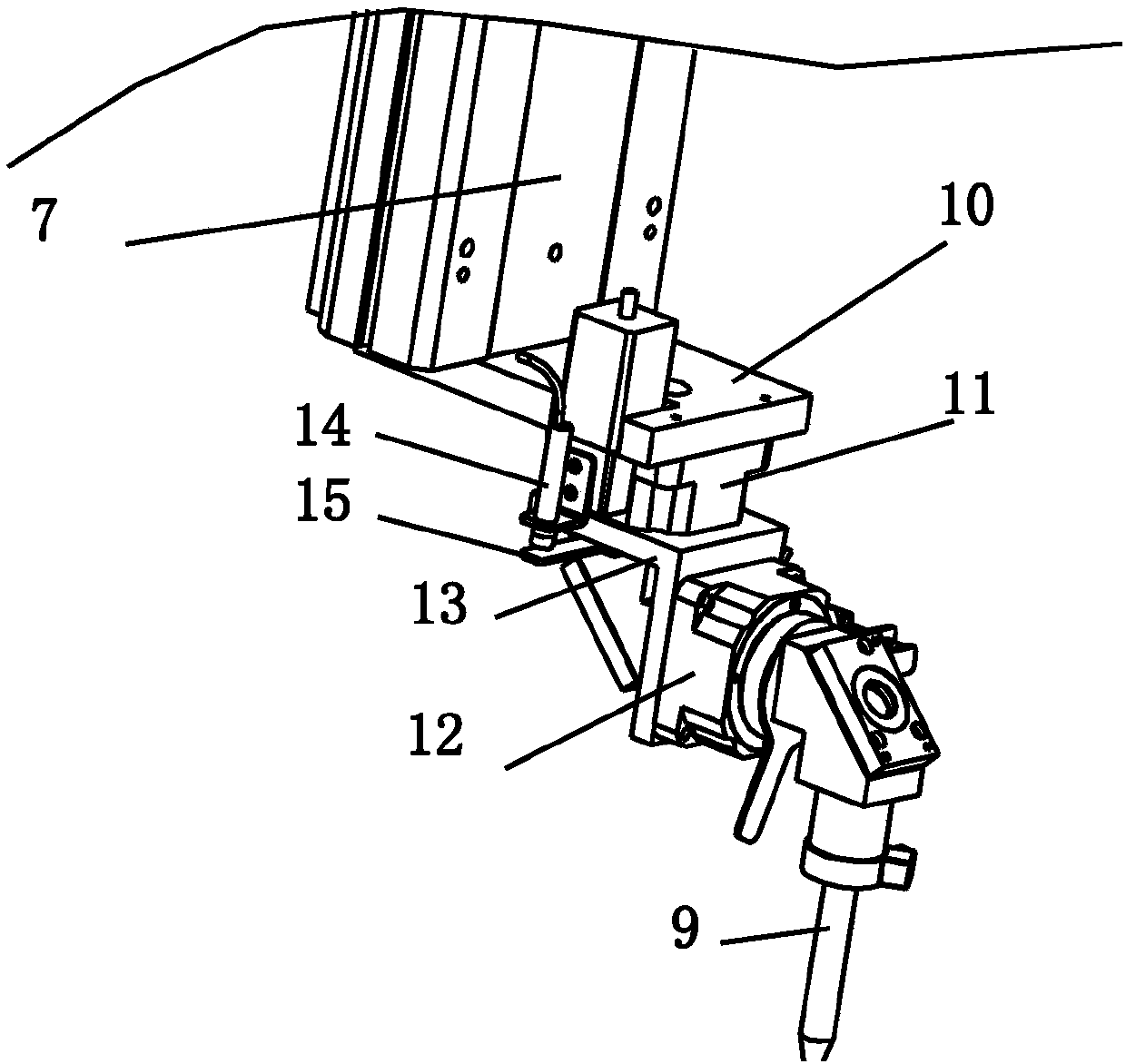

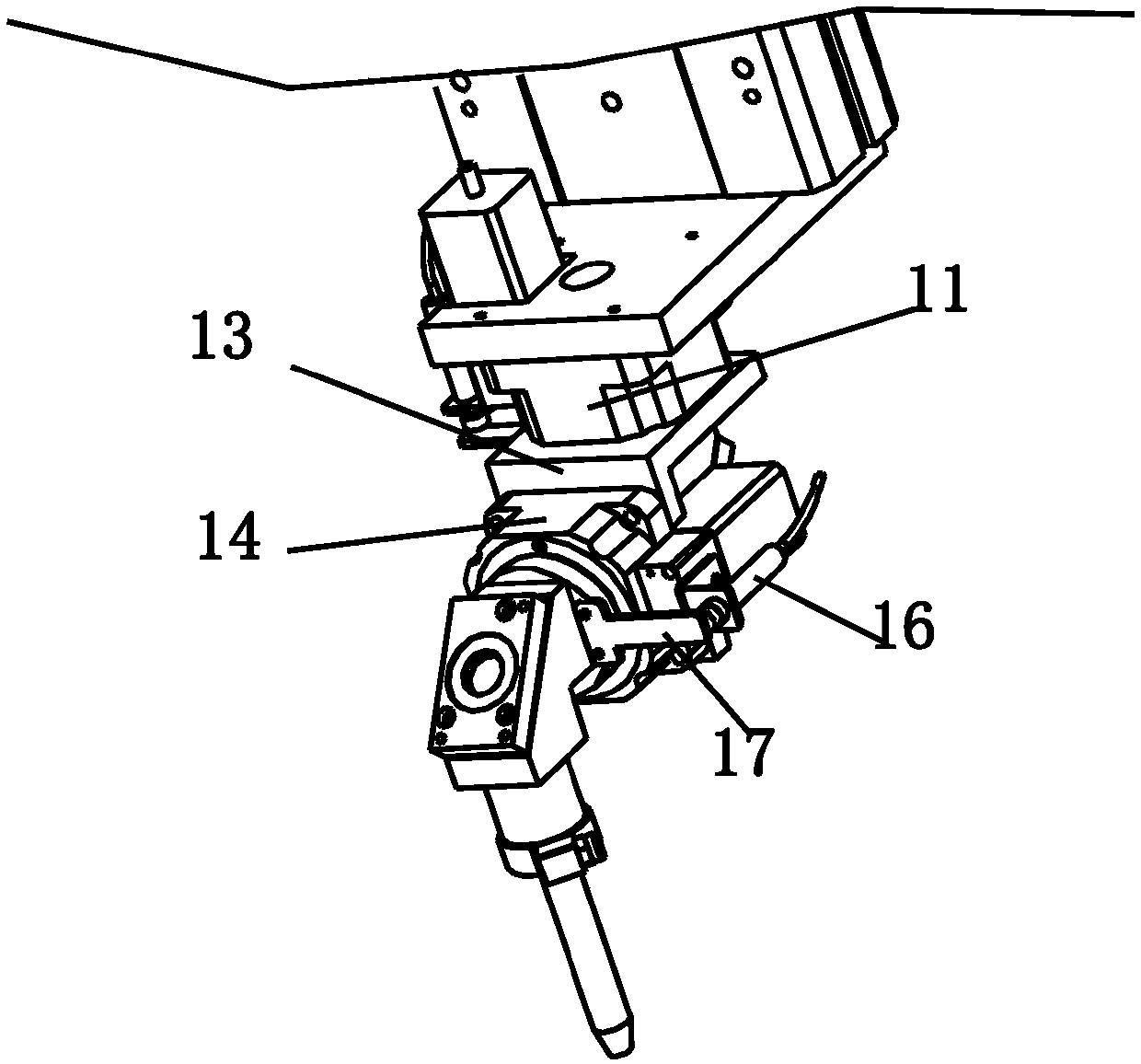

[0029] refer to Figure 1 to Figure 5 A five-axis linkage laser cutting machine is shown, including machine base 1, processing platform 2, gantry 3, Y-axis driving mechanism and X-axis driving mechanism. The Y-axis driving mechanism is installed in the machine base 1 to drive processing translation Move along the Y-axis direction, the X-axis drive mechanism is installed on the crossbeam 4 of the gantry 3, the X-axis drive mechanism includes an X-axis guide mechanism composed of two guide rails and racks arranged horizontally, and an X-axis guide mechanism installed on the X-axis guide mechanism. Drive seat 5, the two guide rails are parallel to each other and extend along the X-axis direction, the rack is arranged between the two guide rails and arranged parallel to the guide rails, the drive seat 5 includes a slide seat and an X-axis drive mounted on the slide seat Motor, the bottom of the sliding seat cooperates with two guide rails through the sliding block, a gear is insta...

Embodiment 2

[0039] Please participate in the attached Figure 1-5 , the cutting process of the five-axis linkage laser cutting machine described in embodiment 1, comprising the following steps:

[0040] S1. Fix the workpiece to be processed on the processing platform 2, and the Y-axis drive mechanism is installed in the machine base 1 to drive the processing platform 2 to move along the Y-axis direction;

[0041] S2. The laser cutting head 9 is driven by the X-axis drive mechanism along the set cutting route according to the shape of the workpiece to be cut, and the Z-axis drives the electric cylinder 7 to realize the movement in the X-axis direction and the height adjustment of the Z-axis respectively;

[0042] S3. Finally, a dual-axis linkage rotating base 8 is installed on the bottom of the Z-axis driving electric cylinder 7, and the laser cutting head 9 is installed on the dual-axis linkage rotating base 8. The laser cutting head 9 can rotate at any angle, and the workpiece to be proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com