Mobile milling and drilling workbench

A workbench, milling and drilling technology, applied in the field of machining, can solve the problems of ineffective sealing, sliding teeth, not vertical, etc., and achieve the effect of convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

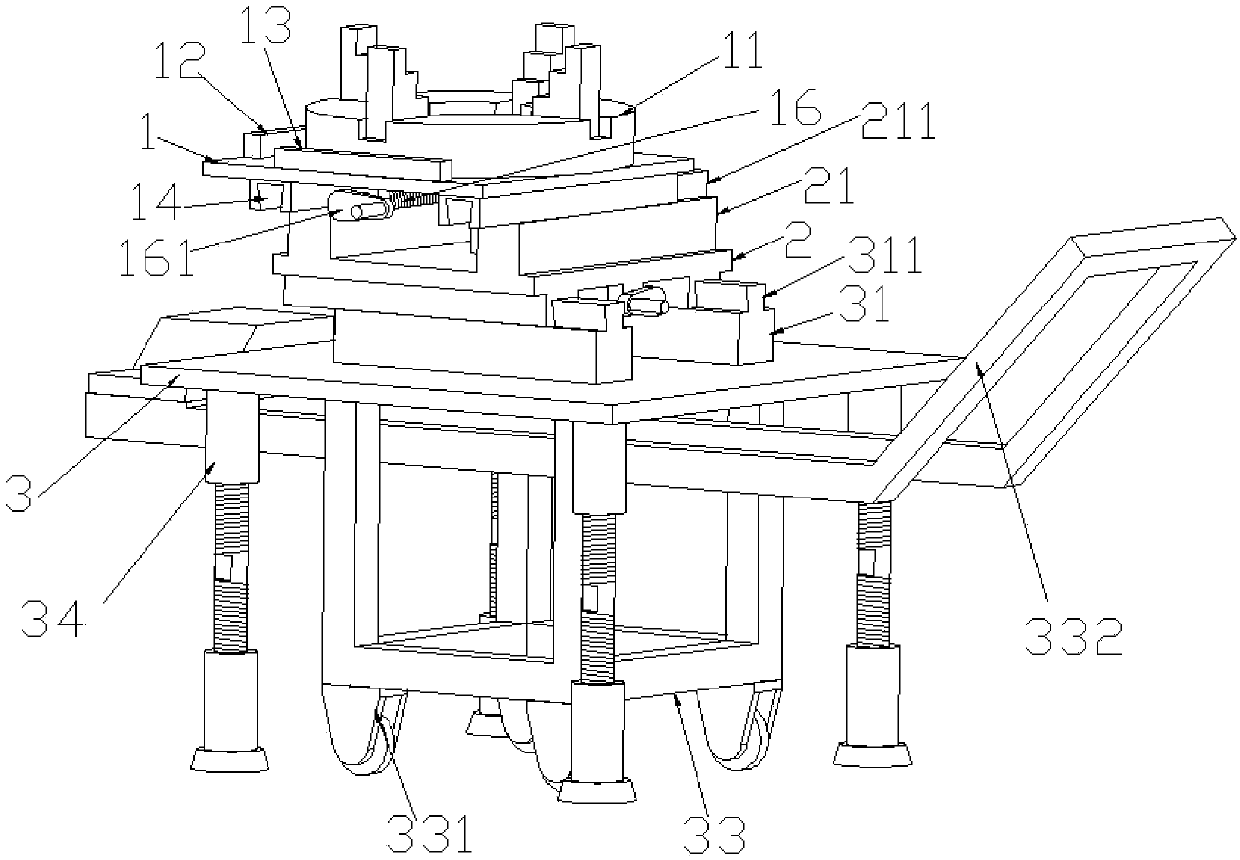

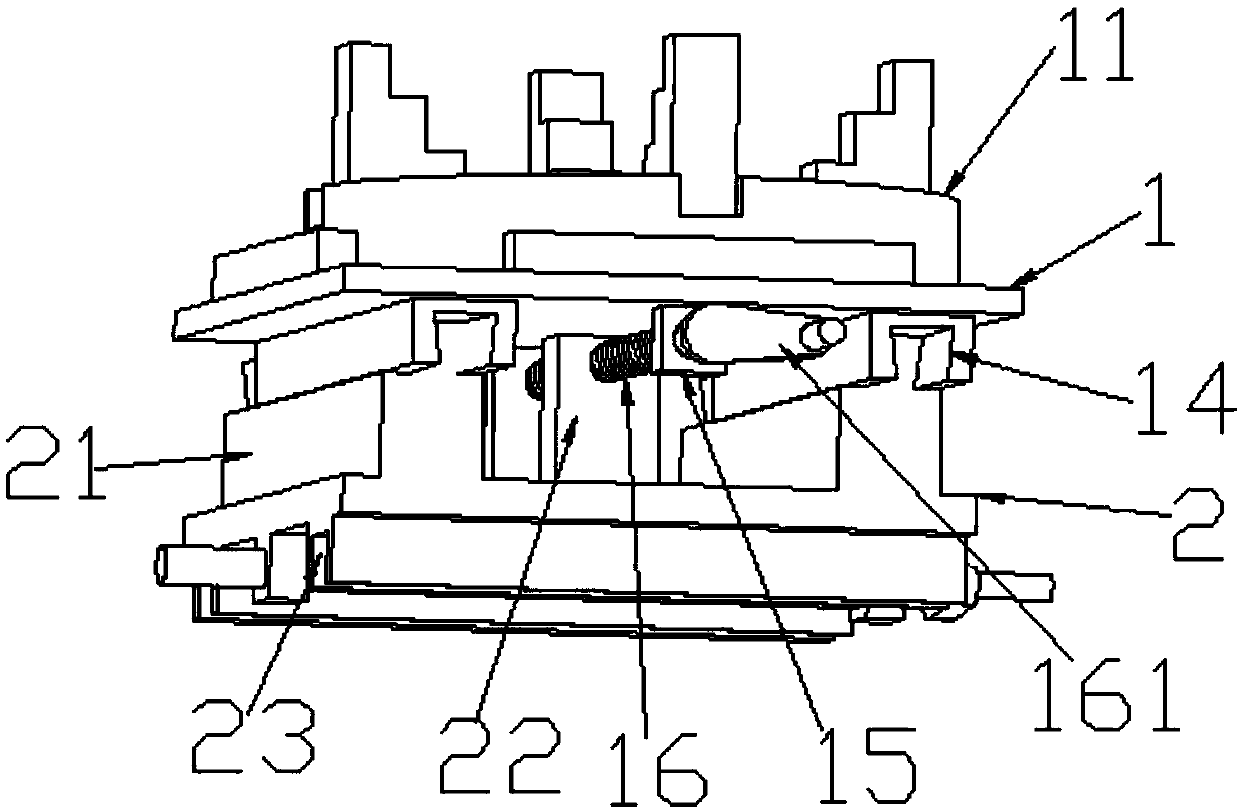

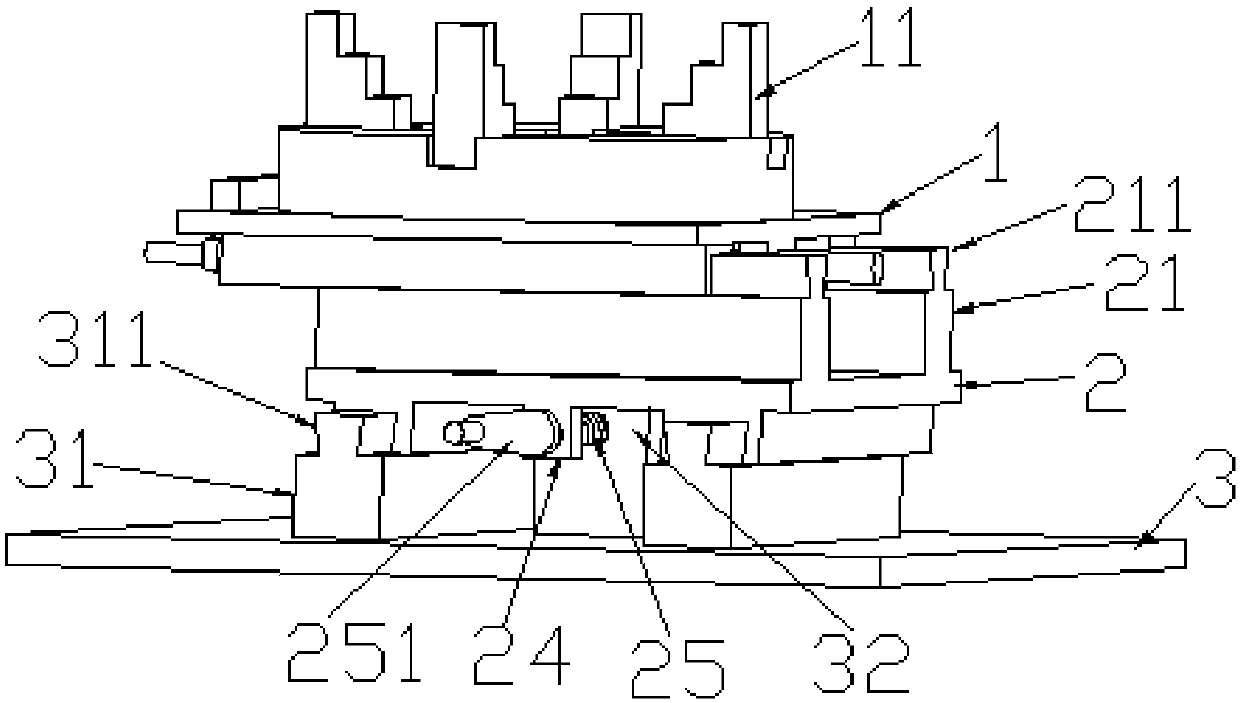

[0040] like Figure 1 to Figure 5 As shown, it includes a base 3, and also includes a first slide 1 and a second slide 2, and the first slide 1 is fixed with a four-jaw chuck 11;

[0041] The first slide plate 1 is also provided with a horizontal level 12 and a longitudinal level 13;

[0042] There are also first slide grooves 14 on both sides below the first slide plate 1;

[0043] A first fixed plate 15 is movable in the middle below the first slide plate 1, and a first screw rod 16 is rotatably sleeved in the first fixed plate 15, and a first handle is fixed at the front end of the first screw rod 16. 161;

[0044] The second sliding plate 2 is provided with a first boss 21, and the first support plate 21 is provided with a first boss 211, and the first boss 211 slides with the first chute 14;

[0045] The second slide plate 2 is provided with a first threaded plate 22, and the first threaded mandrel 16 is screwed and matched with the first threaded plate 22;

[0046] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com