A kind of spunlace non-woven fabric, its preparation method and application

A spunlace non-woven fabric and a preparation process technology, applied in the field of non-woven materials and sanitary materials, can solve problems such as poor liquid holding capacity, limited application of facial masks, etc., and achieve excellent bacteriostatic properties, good liquid holding rate, The effect of good concave and convex feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

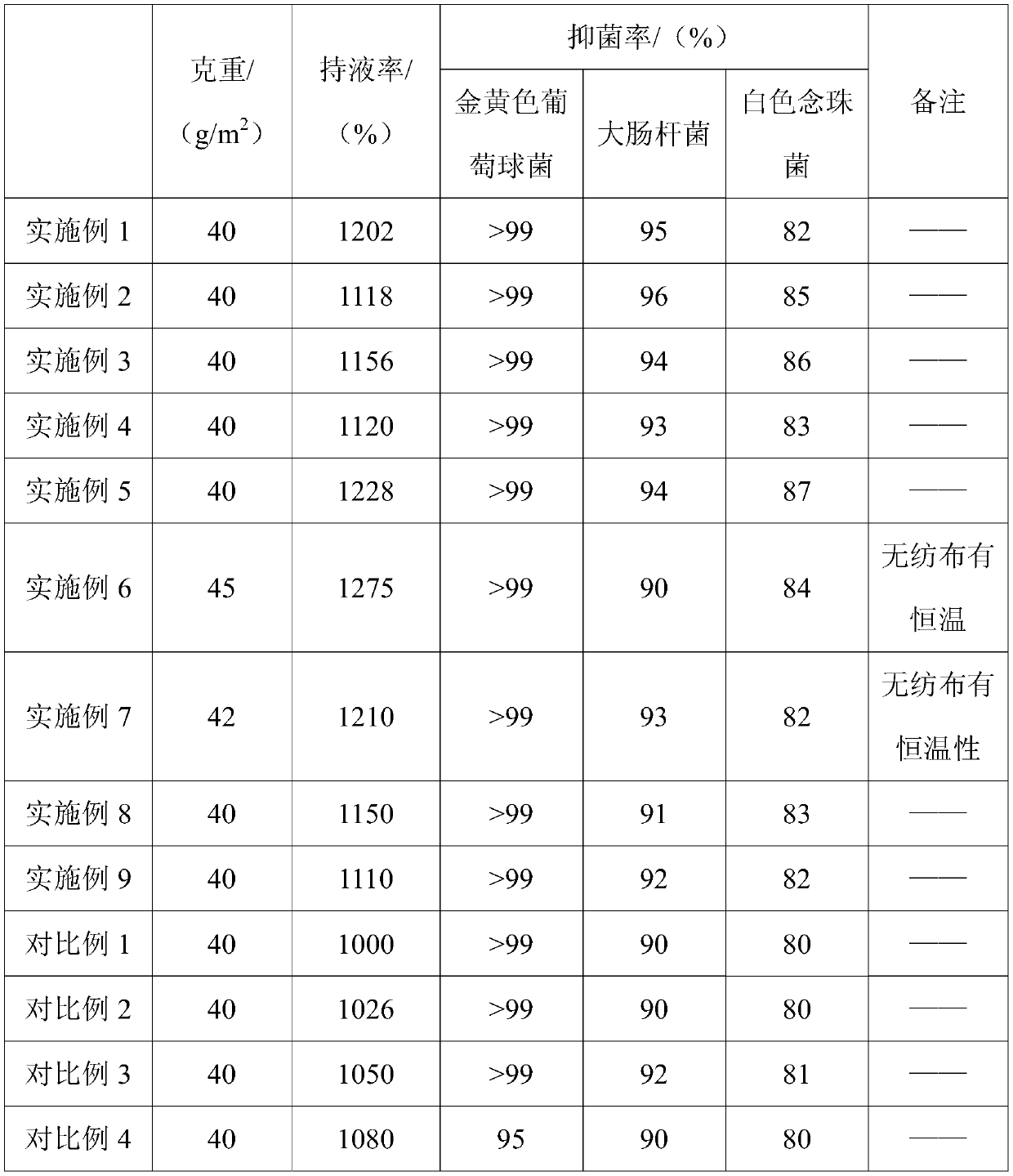

Examples

Embodiment 1

[0062] Using graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D as raw materials, graphene polylactic acid fiber A, graphene polylactic acid fiber B and graphene polylactic acid fiber The total mass of fiber C and graphene viscose fiber D is recorded as 100%, making graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D according to 15%, 25% %, 10% and 50% are blended and opened, then mechanically carded, cross-laid, spunlace entangled, and then dried at 100°C-120°C to obtain a grammage of 40g / m 2 spunlace nonwoven fabric.

Embodiment 2

[0064] Using graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D as raw materials, graphene polylactic acid fiber A, graphene polylactic acid fiber B and graphene polylactic acid fiber The total mass of fiber C and graphene viscose fiber D is recorded as 100%, making graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D according to 15%, 30% %, 15% and 40% are blended and opened, then mechanically carded, cross-laid, spunlace entangled, and then dried at 100°C-120°C to obtain a grammage of 40g / m 2 spunlace nonwoven fabric.

Embodiment 3

[0066] Using graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D as raw materials, graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber The total mass of fiber C and graphene viscose fiber D is recorded as 100%, making graphene polylactic acid fiber A, graphene polylactic acid fiber B, graphene polylactic acid fiber C and graphene viscose fiber D according to 15%, 25% %, 15% and 45% are blended and opened, then mechanically carded, cross-laid, spunlace entangled, and then dried at 100°C-120°C to obtain a grammage of 40g / m 2 spunlace nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com