Tunnel lining trolley end head template

A technology for end formwork and lining trolley, which is applied in tunnel lining, tunnel, shaft lining and other directions, can solve problems such as difficult to meet high-efficiency operation requirements, improve pouring efficiency, affect pouring effect, etc., so as to avoid water leakage and improve The effect of work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

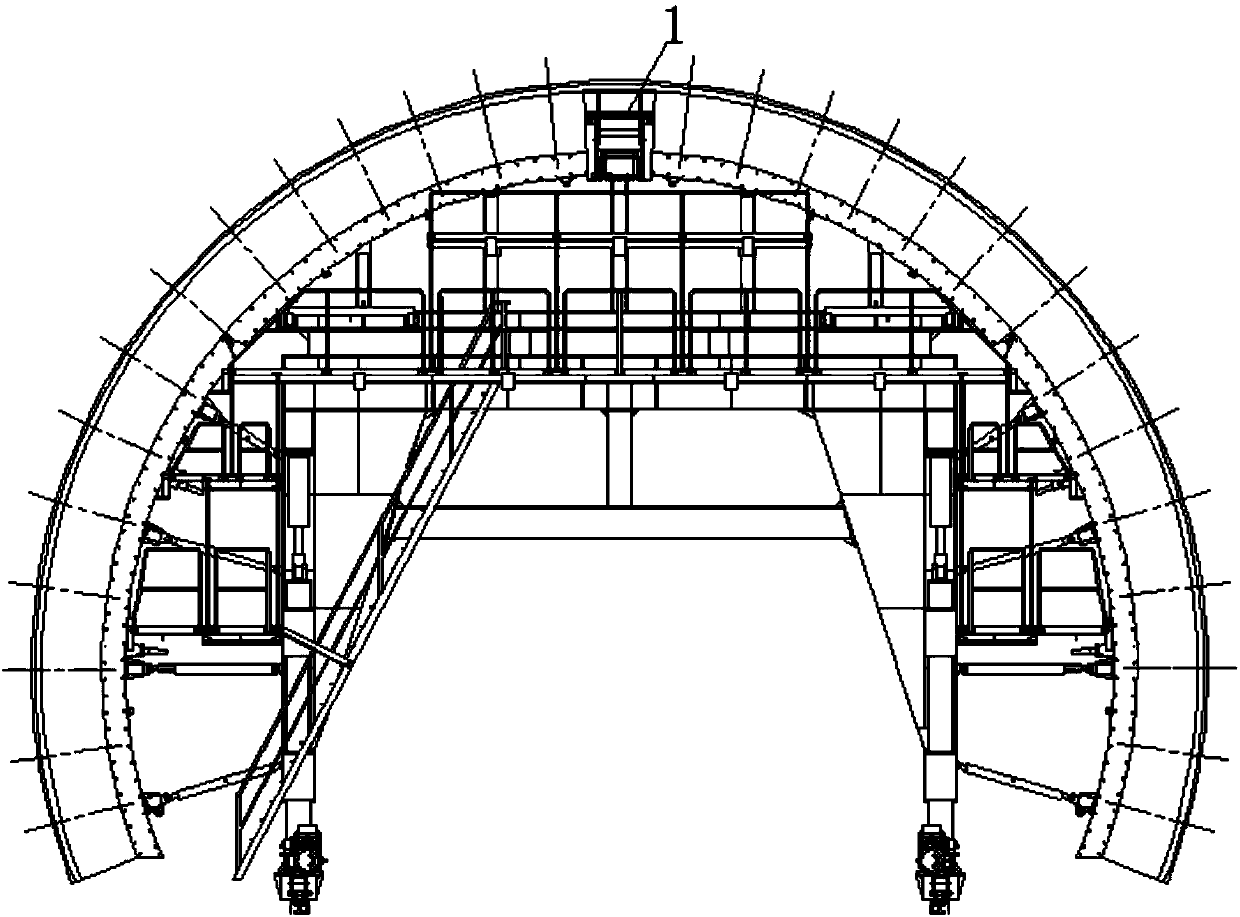

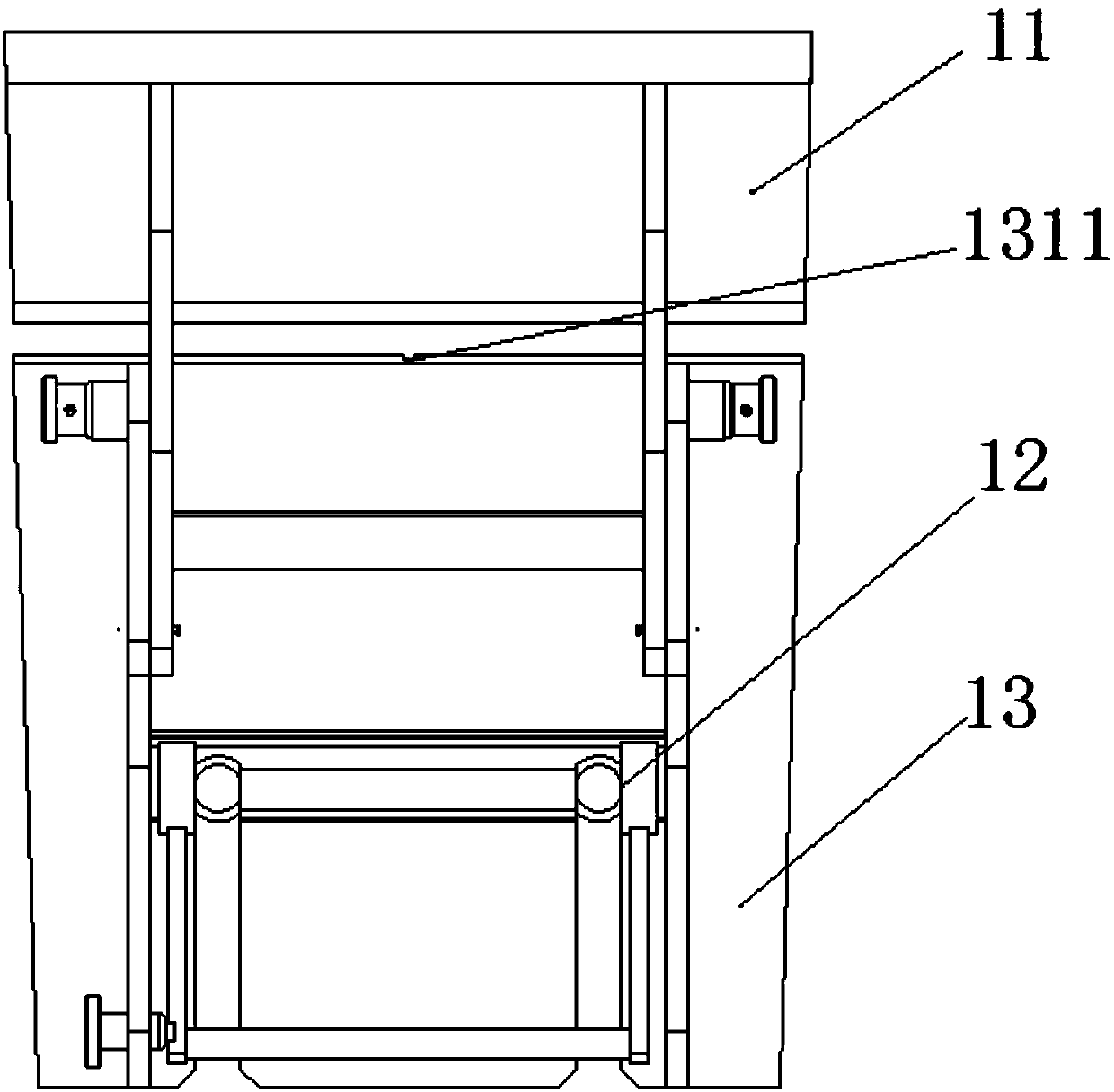

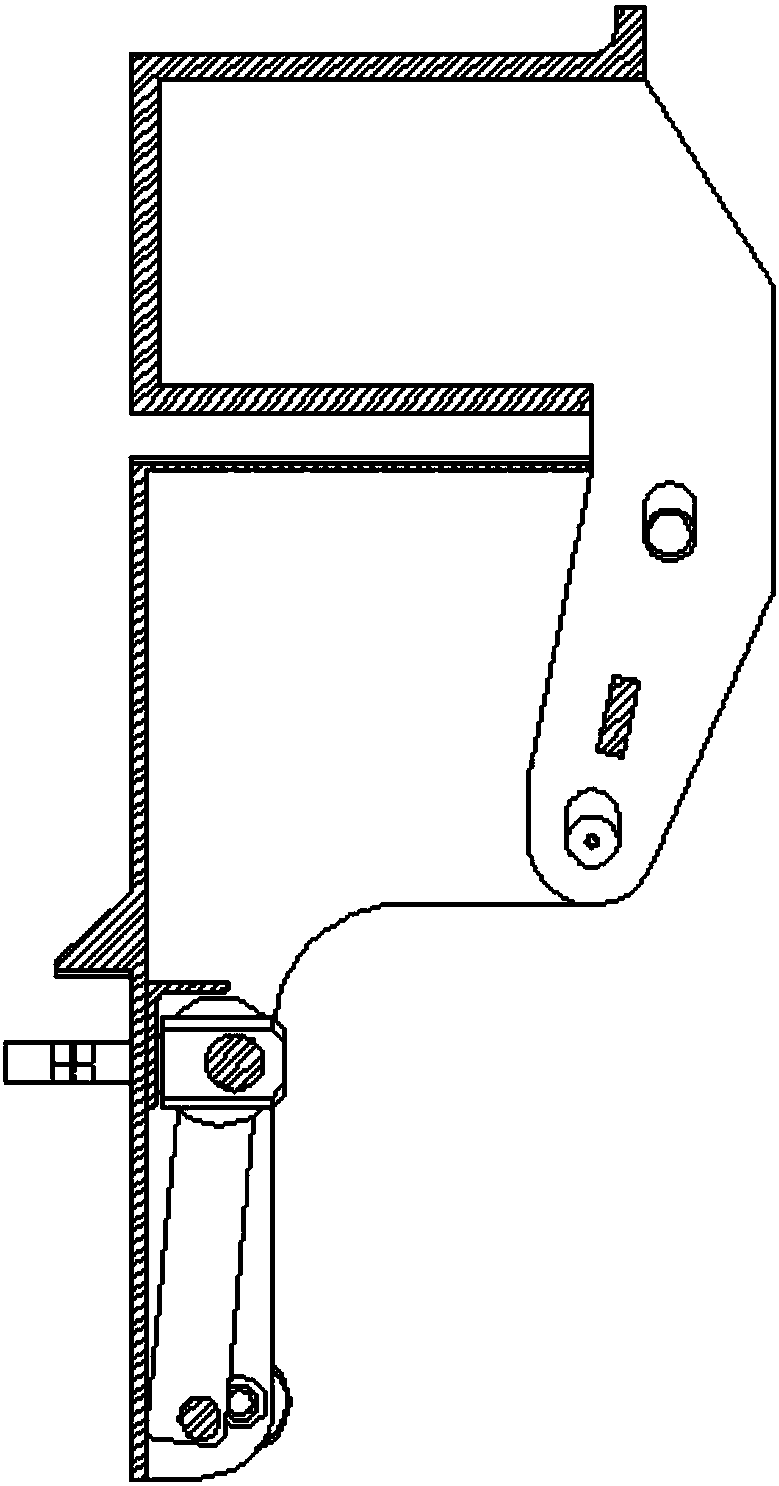

[0027] see Figure 1 to Figure 7 , a tunnel lining trolley end formwork in this embodiment includes a back-adhesive waterstop 2, a buried waterstop 4 and an air bag 3, and also includes a crochet needle 9, an end formwork 1 and a connecting mechanism 12; The terminal template 1 includes an upper template 11 and a lower template 13, one end of the buried waterstop 4 is arranged between the upper template 11 and the lower template 13, and the lower template 13 is provided with a groove 1311, and the crochet 9 has a backward curved sharp end 91 and a handle 92, the hook 9 is placed in the groove 1311 and its backward curved sharp end 91 is inserted into the buried waterstop 4, The handle 92 of the crochet needle 9 is extended in the axial direction of the groove 1311, the upper template 11 is vertically provided with a mounting plate 111 on the side away from the buried waterstop 4, and the lower template 13 is provided with There is an arc-shaped bar 133 with a right-angled tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com