Dual-plane angle measurement method and application thereof

An angle measurement and double-plane technology, applied in the mechanical field, can solve problems such as high cost, long CT, and poor dynamic repeatability, and achieve the effects of optimal cost, best stability, and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be explained in more detail below. However, it should be understood that within the scope of the present invention, the above-mentioned technical features of the present invention and the technical features specifically described in the following (such as embodiments) can be combined with each other to form new or preferred technical solutions. Due to space limitations, we will not repeat them here.

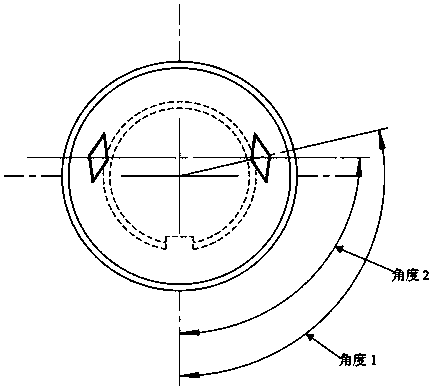

[0022] As shown in the figure: the present invention provides a method for measuring a biplane angle, comprising the following steps:

[0023] Step 1. Select the marking block, which is provided with four through holes, and the upper surface of the marking block is provided with two diamond-shaped openings, and the lower surface of the marking block is provided with a gap. The thickness of the marking block is equal to the front surface of the product to be tested. The distance between the focal plane and the back focal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com