A production line 3D monitoring system combining virtual reality

A combination of virtual and real, monitoring system technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of three-dimensional visual display of manufacturing information, insufficient data visualization, statistical report methods that cannot meet the needs of manufacturing management, etc. , to achieve the effect of guaranteeing uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

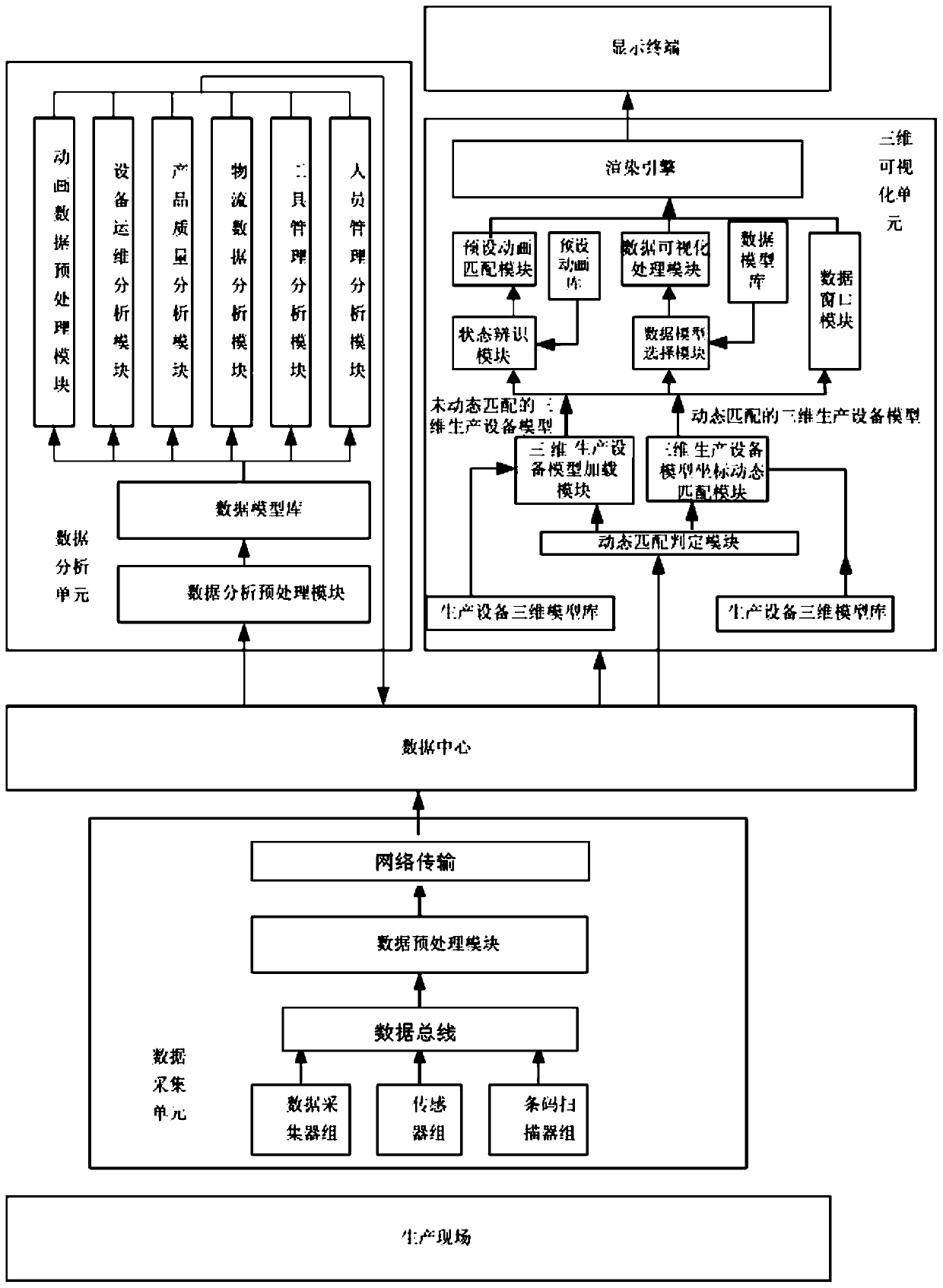

[0043] like figure 1 as shown,

[0044] A three-dimensional monitoring system for a production line combining virtual reality, including:

[0045] Data acquisition unit: used to lay out data acquisition devices in production equipment, read data related to production equipment to form raw data, and output the raw data to the data center after preprocessing; specifically, such as figure 1 As shown, the data acquisition unit includes a network transmission unit connected to the data center, a data preprocessing module connected to the network transmission unit, a data bus connected to the data preprocessing module, a data collector group connected to the data bus, a sensor group, The barcode scanner group, the data acquisition unit collects the basic information of the production site through the data collectors, sensors, barcode scanners and other equipment arranged on the production equipment and production stations, including the operation status information of the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com