Folding mechanism

A technology of edge folding knife and edge angle, which is applied in the direction of structural parts, battery assembly machines, electrical components, etc., can solve the problems of inconsistent battery edges, unguaranteed safety, and affecting battery specifications, etc., to achieve consistent edge folding specifications, Basic hemming specifications and high hemming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

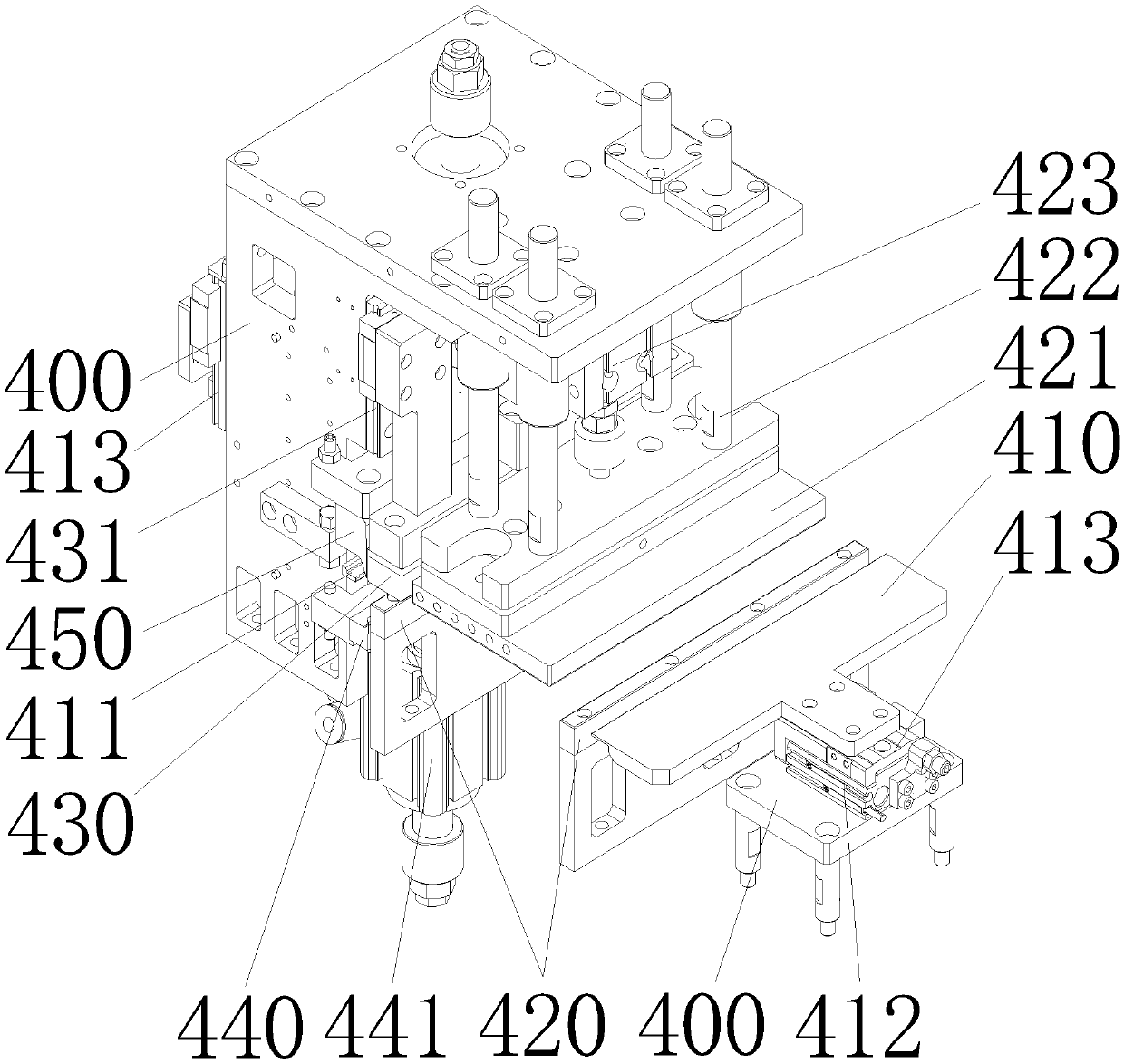

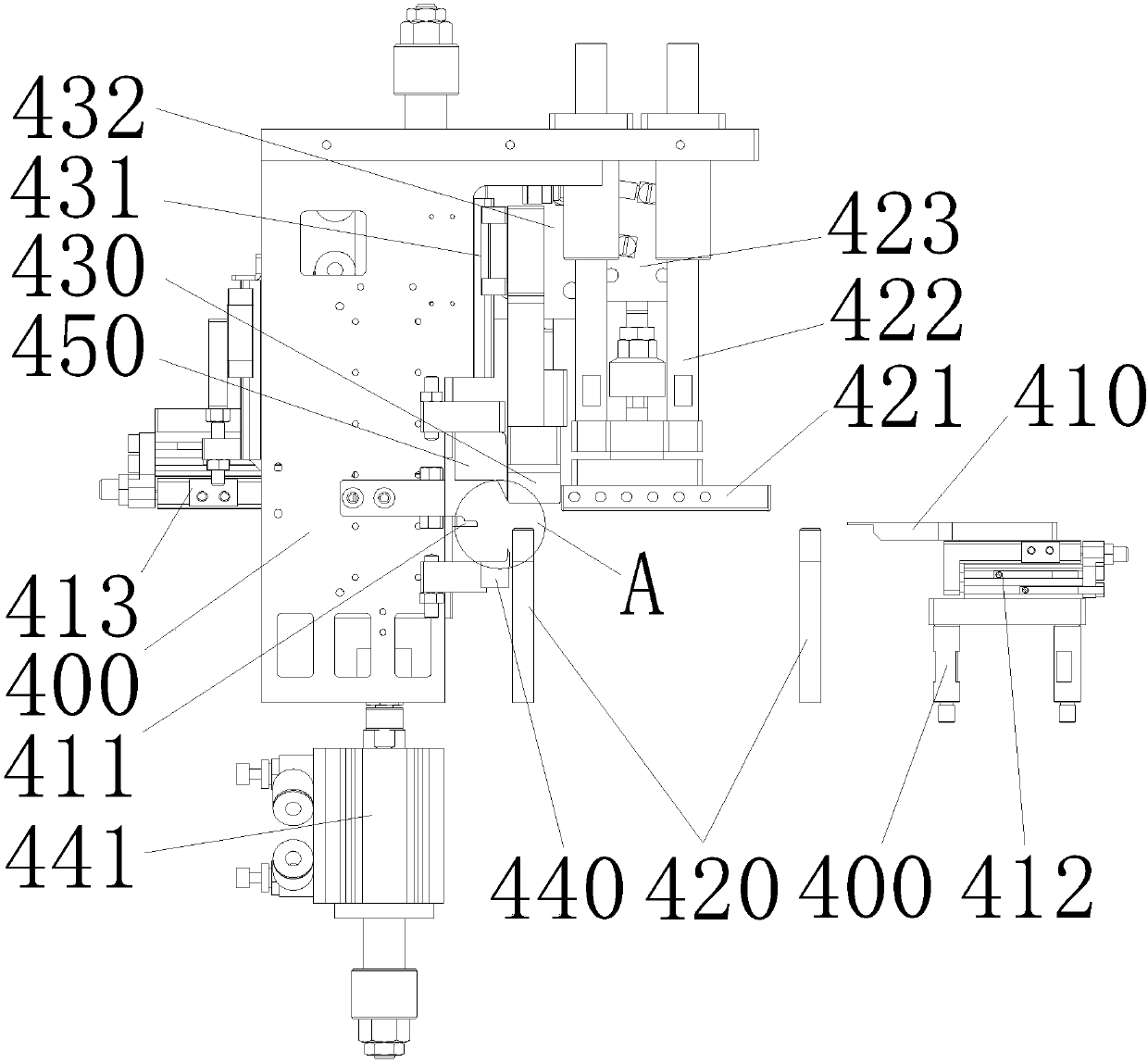

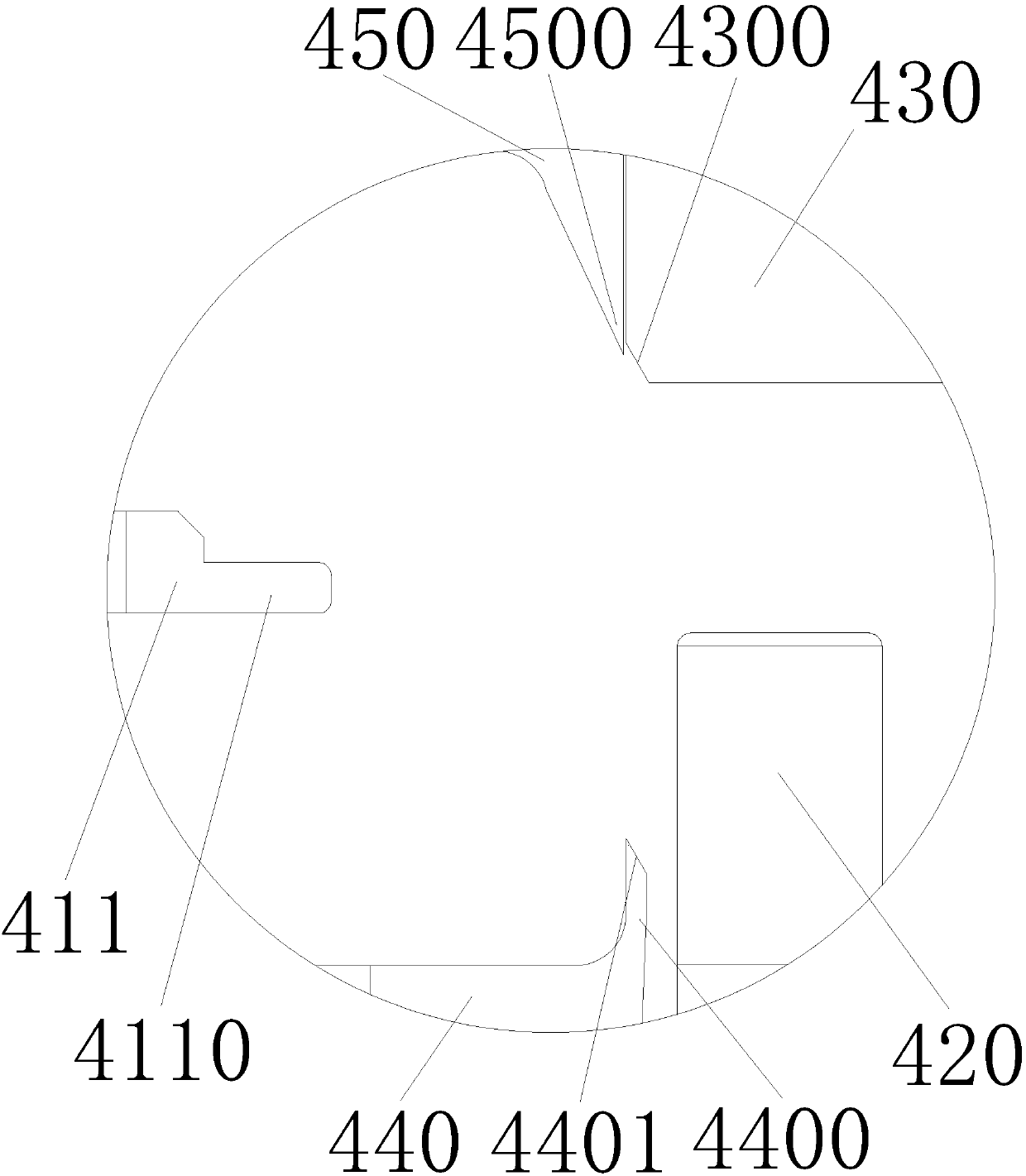

[0026] refer to Figure 1 ~ Figure 4 As shown, the present invention discloses a hemming mechanism, which includes a hemming base (not shown in the figure) and a hemming support 400, and the hemming support 400 is arranged on the hemming base. The folding bracket 400 is divided into two parts, the main part is an inverted "L" shape, and the accessory part is a platform, and the main part and the accessory part are set separately.

[0027] The main part of the above-mentioned hemming bracket 400 is provided with a hemming push plate driving source 413, a hemming pressing plate driving source 423, a corner pressing plate driving source 432, a lower hemming knife driving source 443 and an upper hemming knife driving source (not shown in the figure). show). The accessory part of the above-mentioned hemming bracket 400 is provided with a driving source 413 for hemming push plate.

[0028] The above two hemming push plate driving sources 413 are arranged opposite to each other in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com