Manufacturing method of pef raw yarn

A manufacturing method and yarn technology, applied in the direction of yarn, melt spinning, filament/thread forming, etc., can solve the problems of large environmental burden and achieve high production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

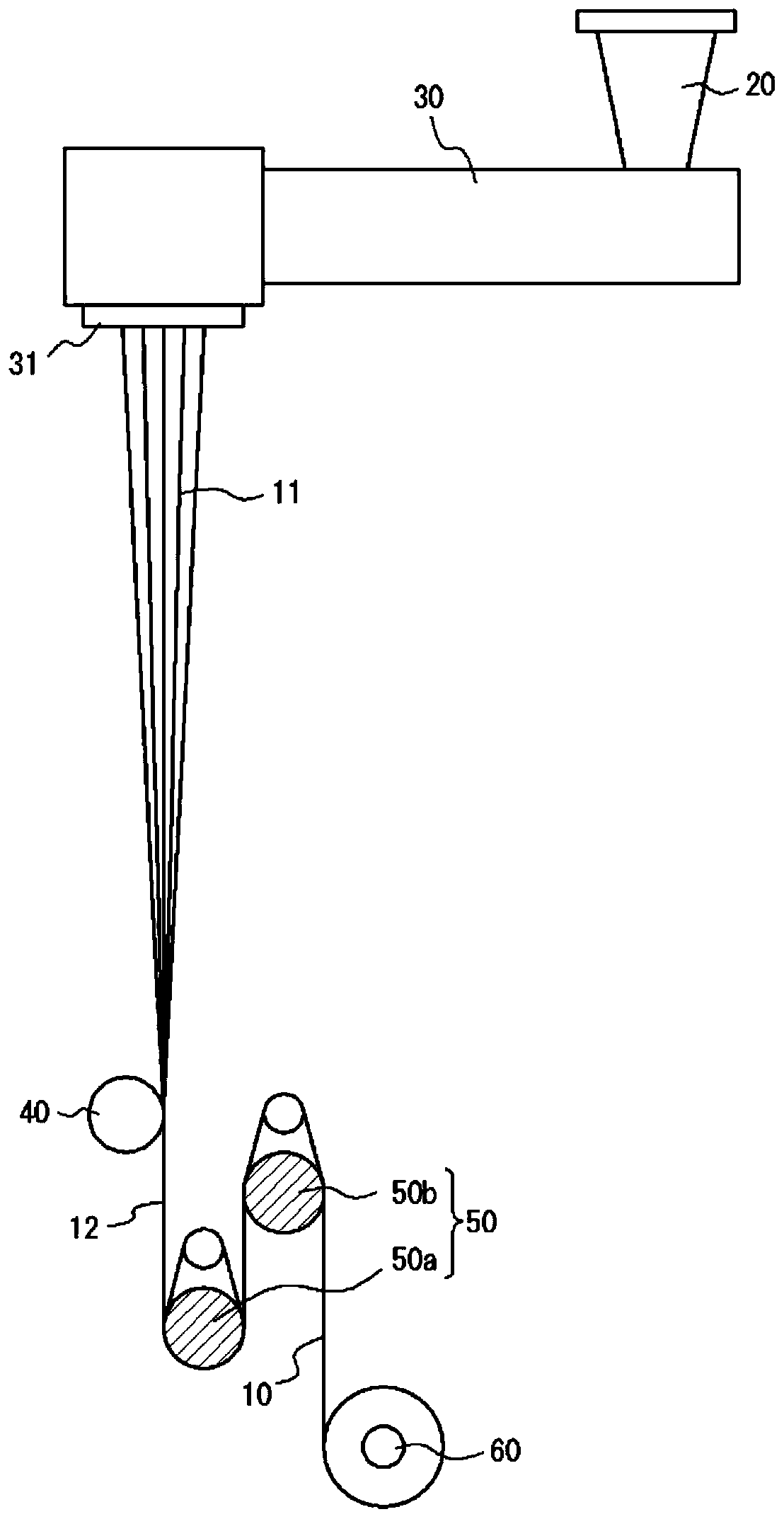

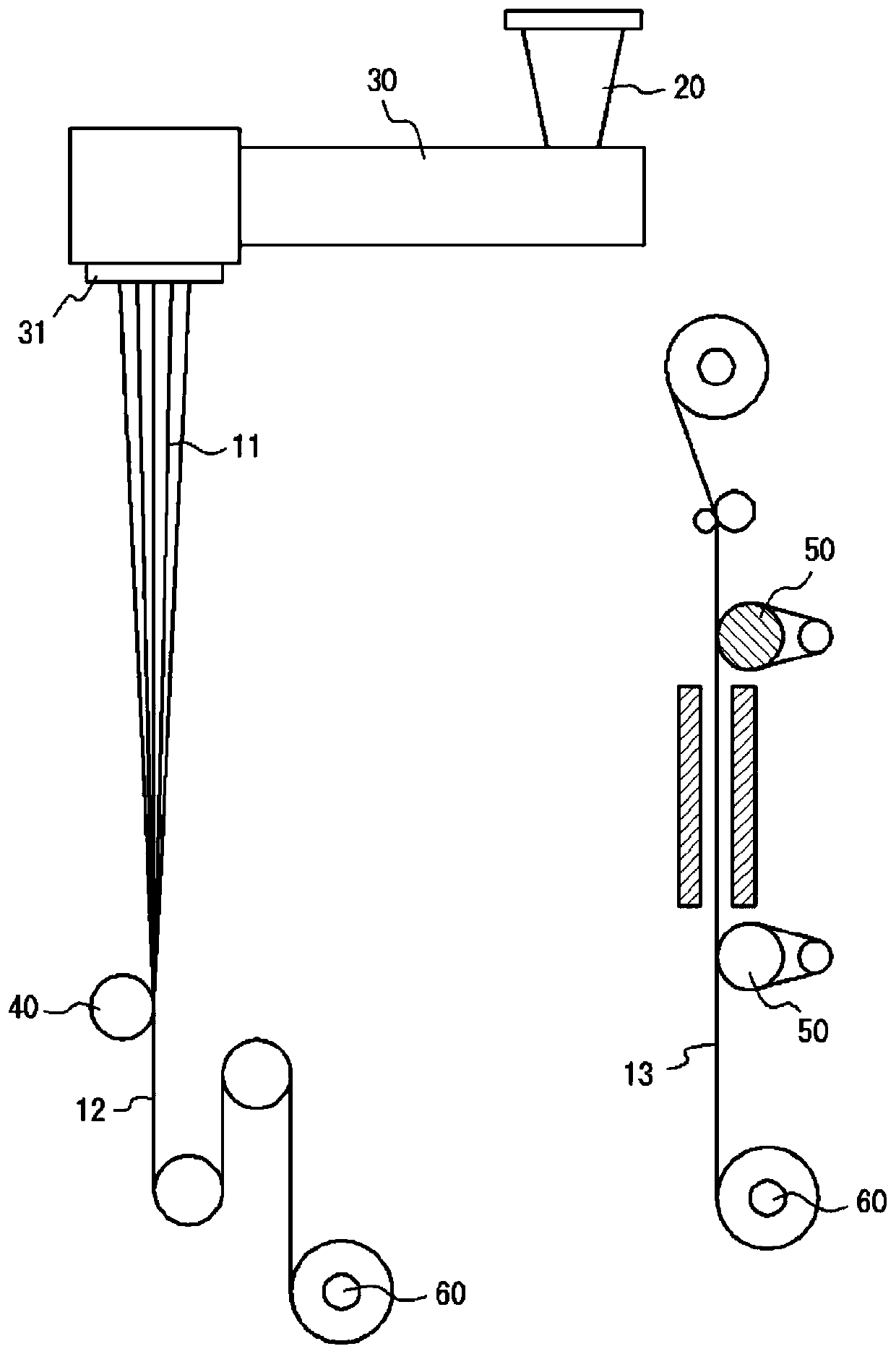

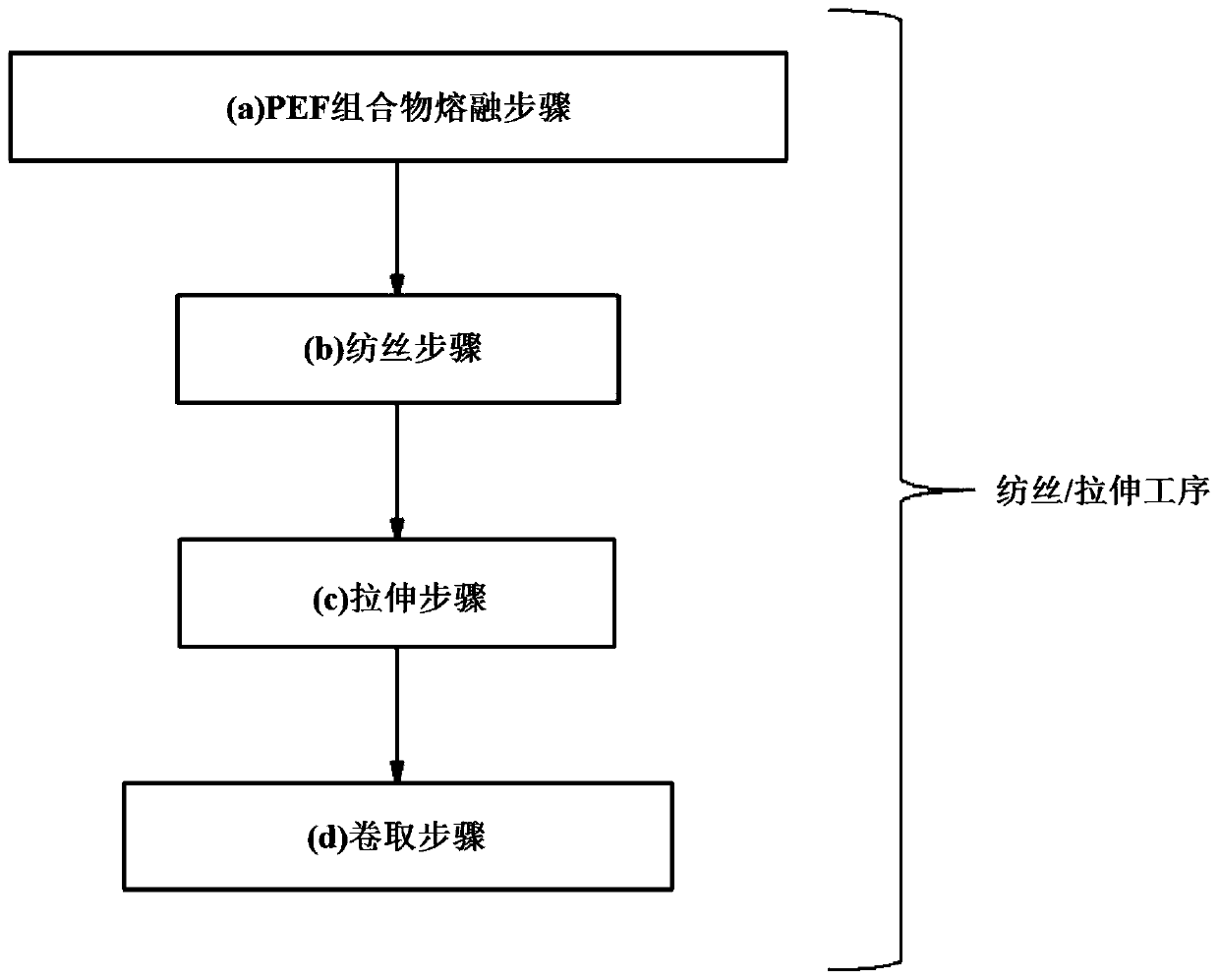

Method used

Image

Examples

Embodiment 1

[0099] A PEF composition consisting only of 100% bio-based PEF having a Mw of 75,600 and an intrinsic viscosity of 0.76 dl / g was melt spun by passing it through a 96-hole die at an extrusion temperature of 275°C, and 96 The filaments were bundled into an undrawn yarn, which was continuously drawn without recovery, and then wound up to obtain a PEF raw yarn having a denier of 1,100 dtex (11.5 dtex per filament). The spinning draft is as shown in Table 1 and the time from the completion of extrusion of the filament in the spinning step to the start of drawing the undrawn yarn is not longer than 10 seconds.

Embodiment 2-3 and comparative example 1

[0101] PEF raw yarns were obtained as in Example 1, except that the spinning draft conditions were changed.

Embodiment 4

[0103] PEF raw yarns were obtained as in Example 1, except that 100% bio-based PEF with an intrinsic viscosity of 1.10 dl / g was used and the extrusion temperature was set at 310°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com