Motor vehicle vacuum pump

A technology of vacuum pump and motor vehicle, applied in the direction of machine/engine, pump, pump components, etc., can solve the problem of deterioration of pump power consumption, achieve the effect of improving efficiency and reducing noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

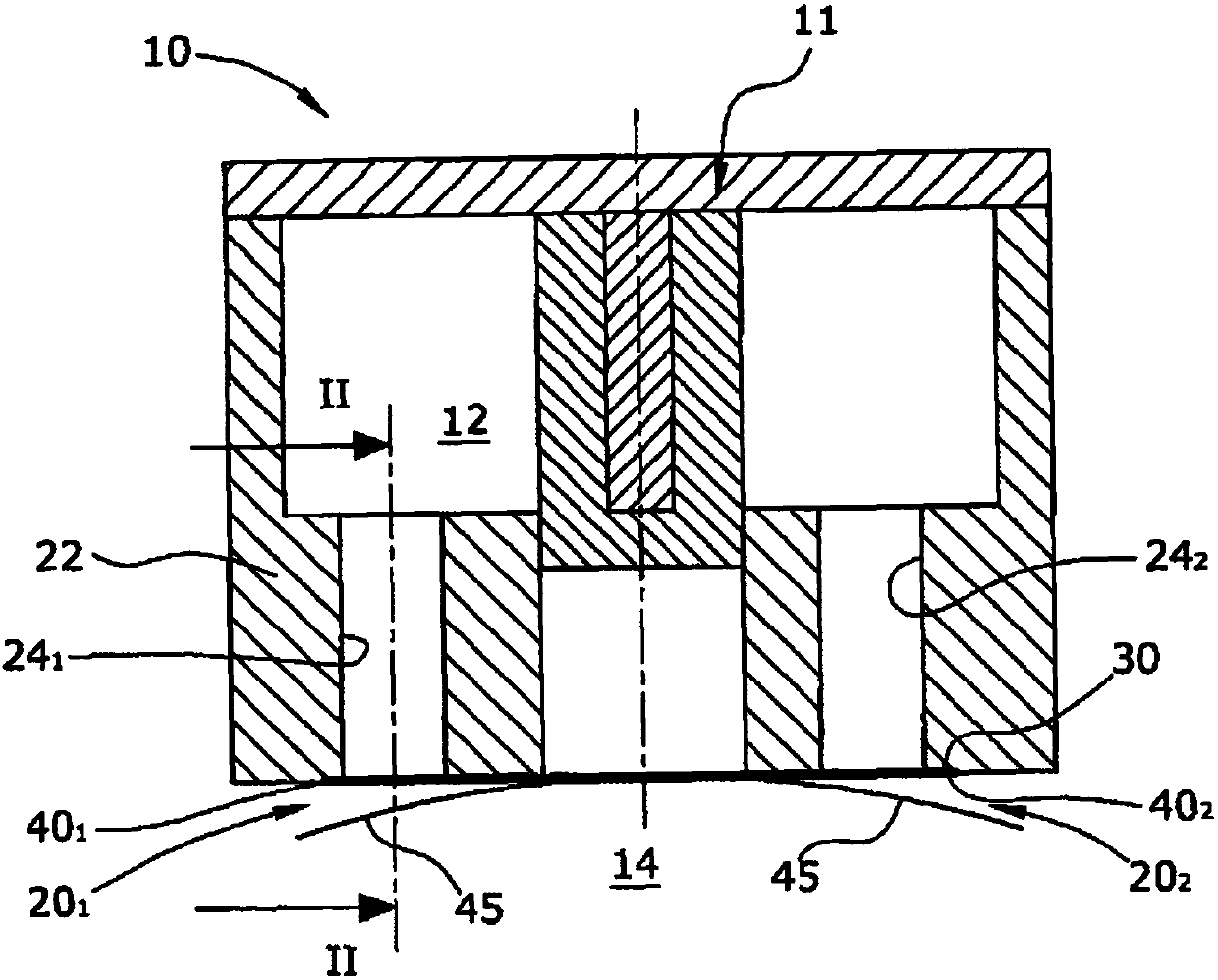

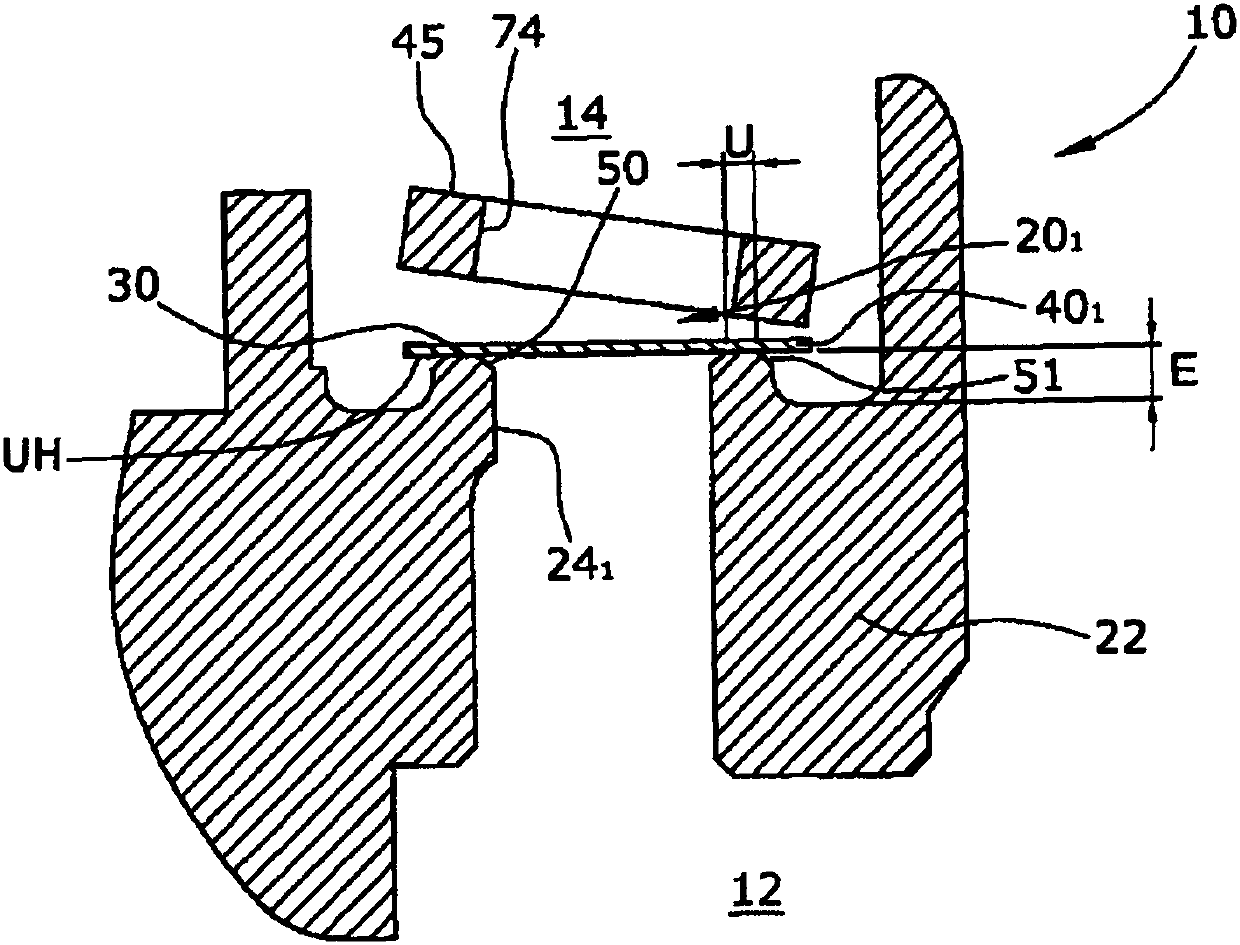

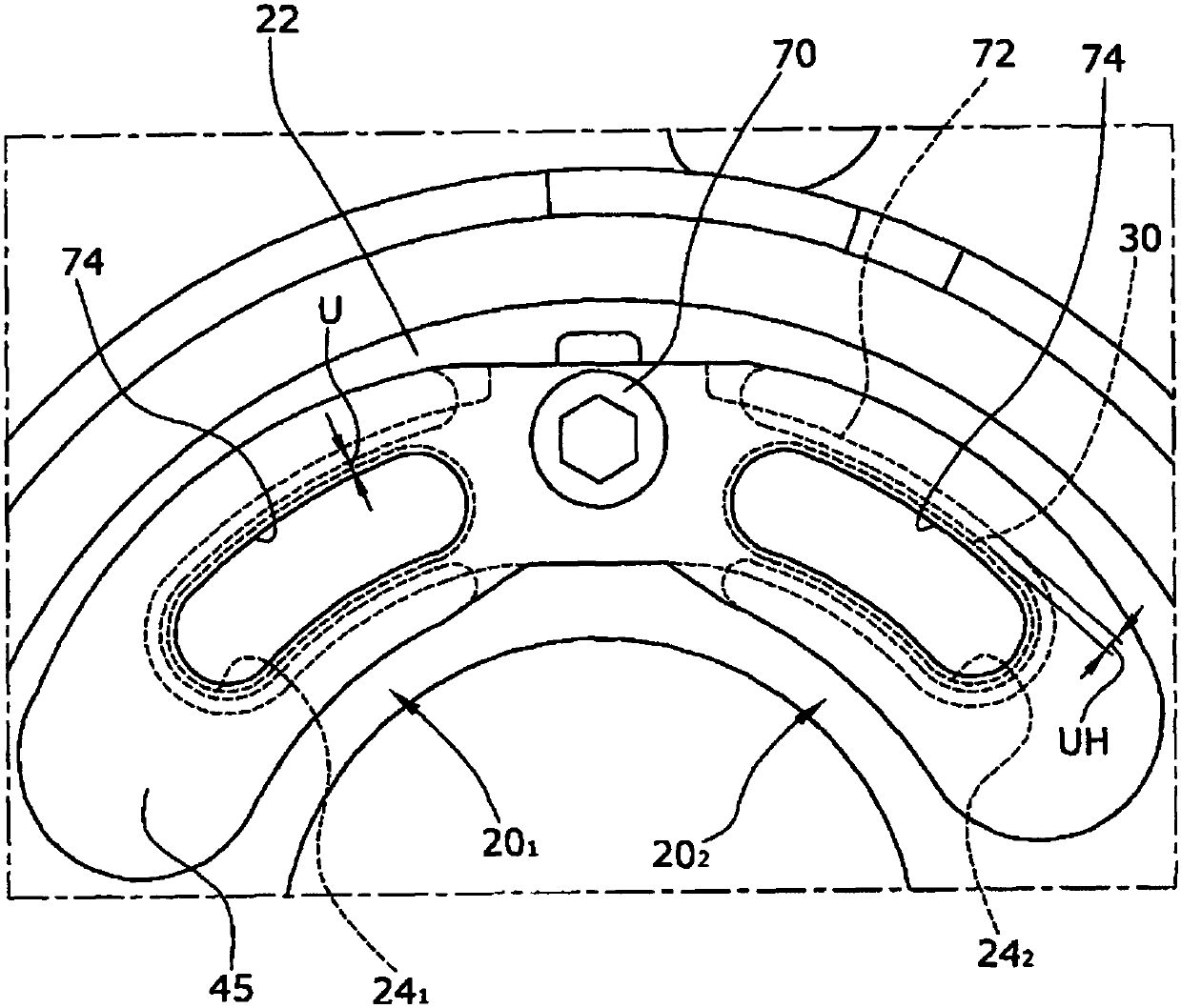

[0025] figure 1 A motor vehicle vacuum pump 10 according to the invention is shown. The vacuum pump 10 forms a pump chamber 12 in which gas is compressed by a rotating pump rotor 11 . A partition 22 separates the pump chamber 12 from the outlet chamber 14 . In the partition wall 22, a kidney-shaped valve hole 24 is designed for forward rotation 1 and kidney-shaped valve hole 24 during reverse rotation 2 . For fluid communication between the pump chamber 12 and the outlet chamber 14, the vacuum pump 10 has an outlet valve 20 designed as a check valve for forward rotation. 1 and outlet valves designed for reverse rotation of the check valve 20 2 . Outlet valve 20 1 ,20 2 With kidney-shaped leaf spring 40 as valve body 1 ,40 2 , the leaf spring closes the valve hole 24 in the closed state 1 ,twenty four 2 .

[0026] exist figure 2 The outlet valve 20 is shown by forward rotation when 1 Cutaway cutaway view. Outlet valve 20 during forward rotation 1 Made of kidne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com