Seedling taker and plant transplanting machine

A seedling tray and driver technology is applied in the field of seedling pickers to avoid simultaneous operation, reduce equipment interference and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

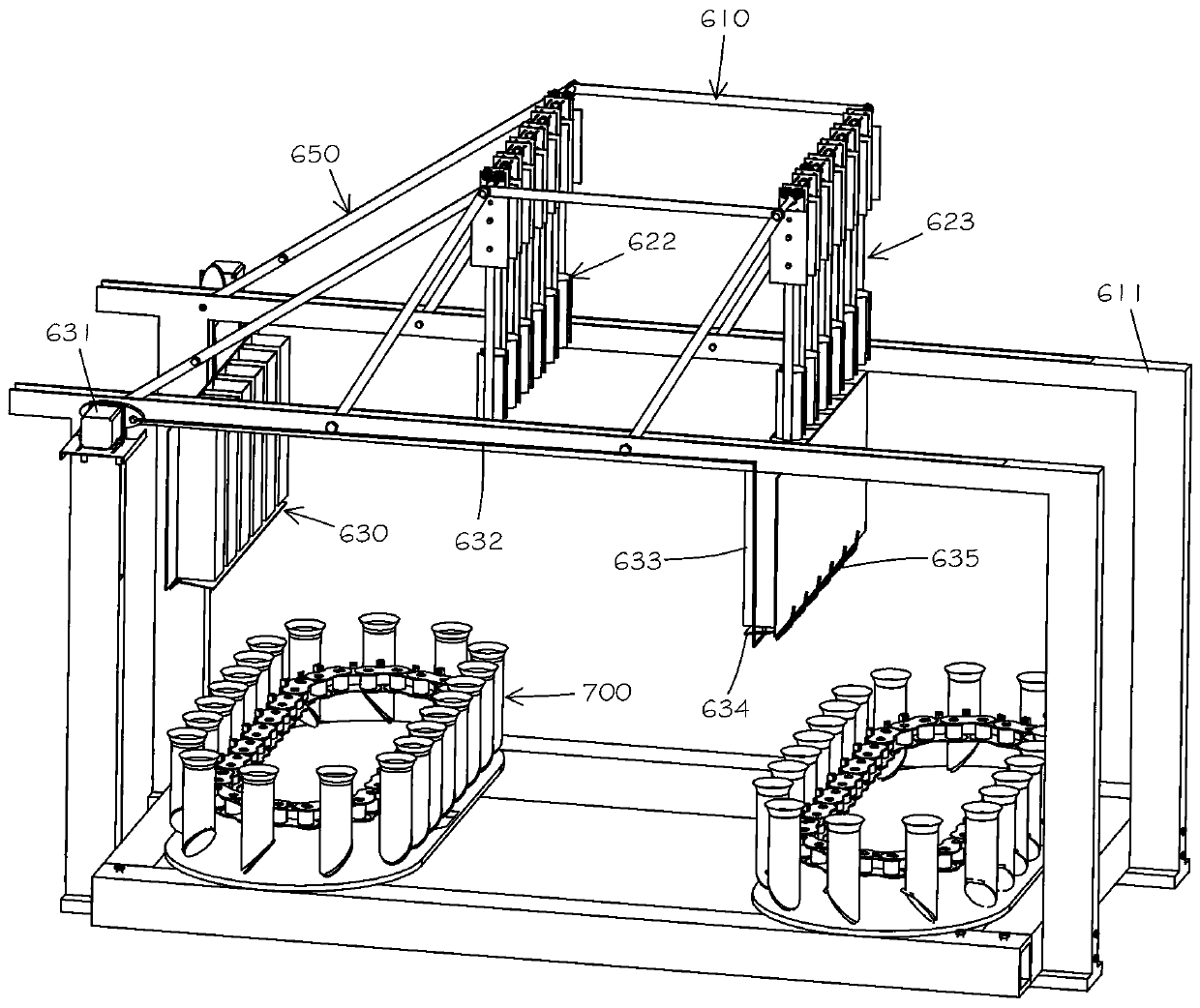

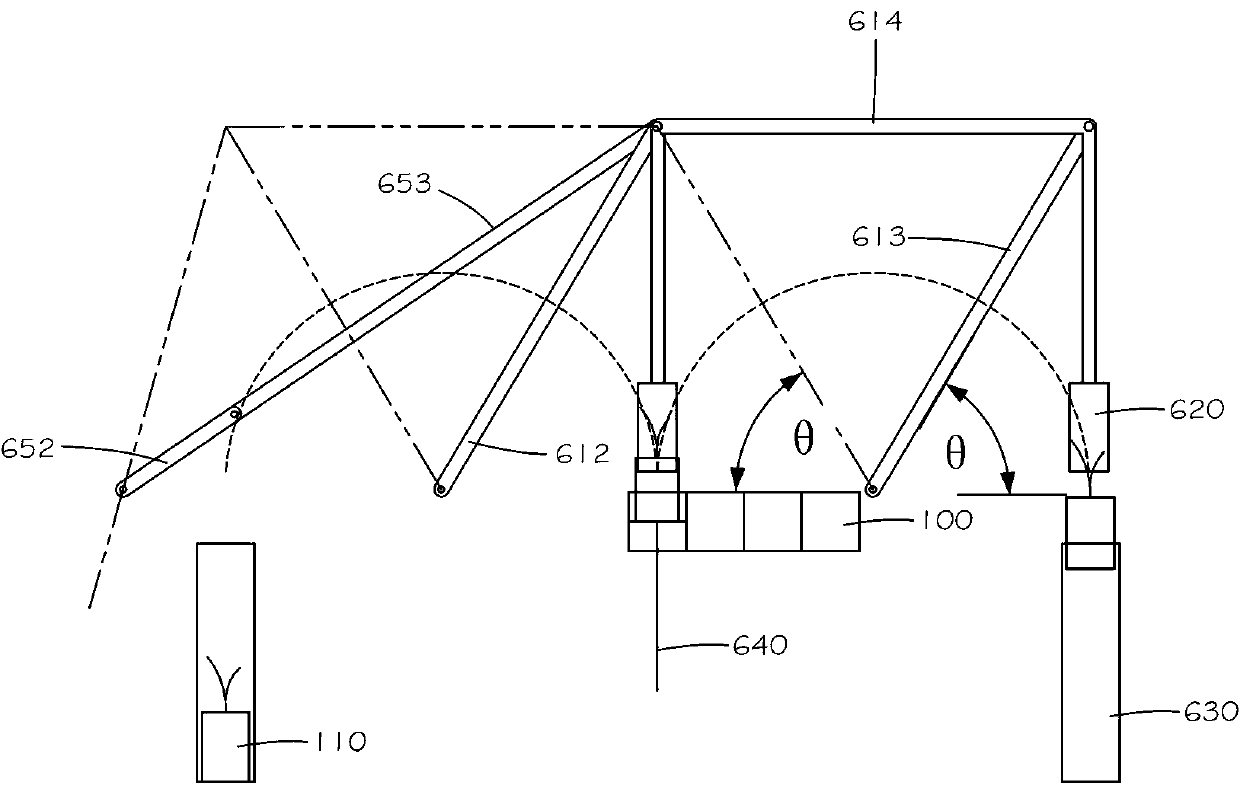

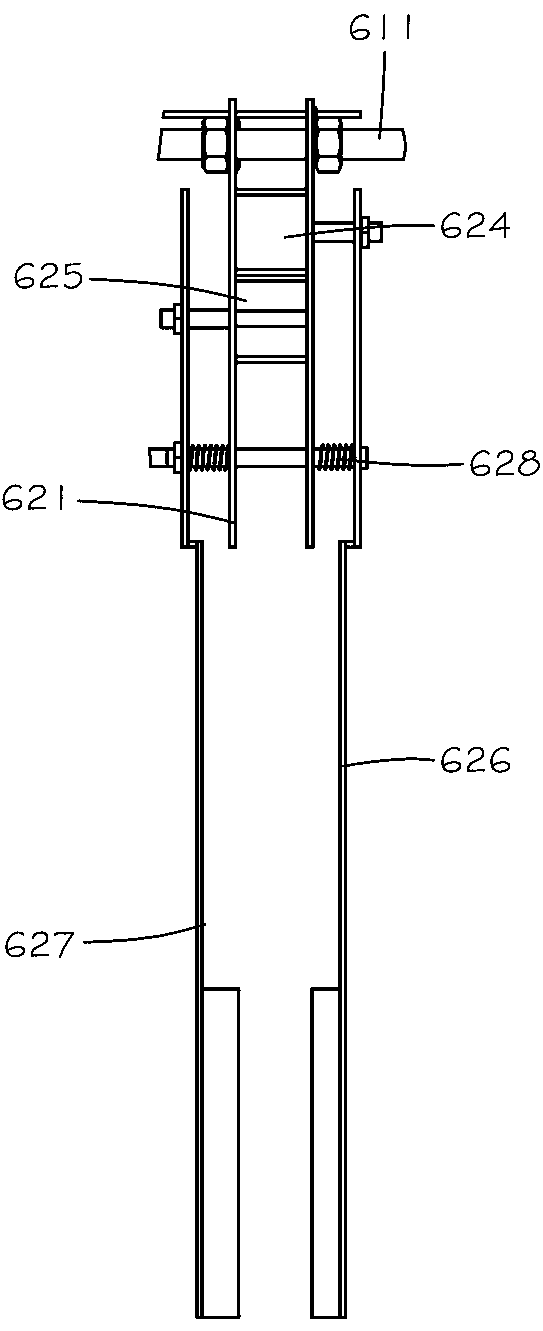

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0044] Review of prior art

[0045] Multi-row seedling feeders are often carried on the automatic transplanting machine. The fully automatic transplanting machine of 201120174476.9 includes a seedling supply device for supplying seedlings to a machine body provided with a traveling device, a seedling planting body for planting seedlings in a field by using a vertical movement mechanism, and a seedling loading platform. This seedling loading platform is provided with multiple layers of seedling loading parts, the lower seedling loading parts are fixed on the seedling platform support frame, and the seedling loading parts above the lower seedling loading parts are configured to be able to rotate upward. In the actual design, the seedling feeder should be kept moving smoothly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com