Intelligent stirring machine for powder

A mixer and powder technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve problems such as poor uniformity, failure to improve material mixing uniformity, and failure to solve upper and lower material mixing, etc., to achieve Improve the uniformity, improve the stability, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

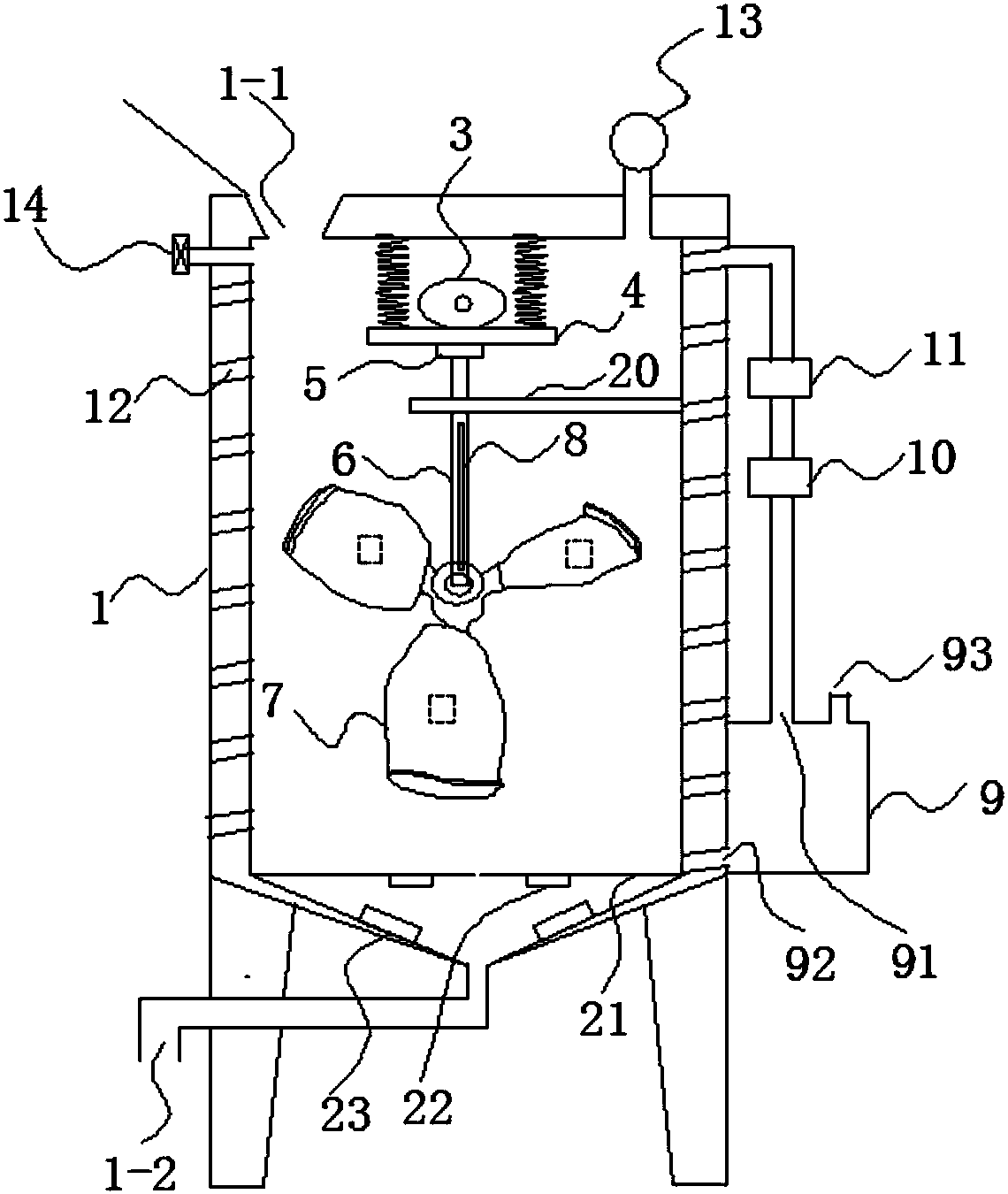

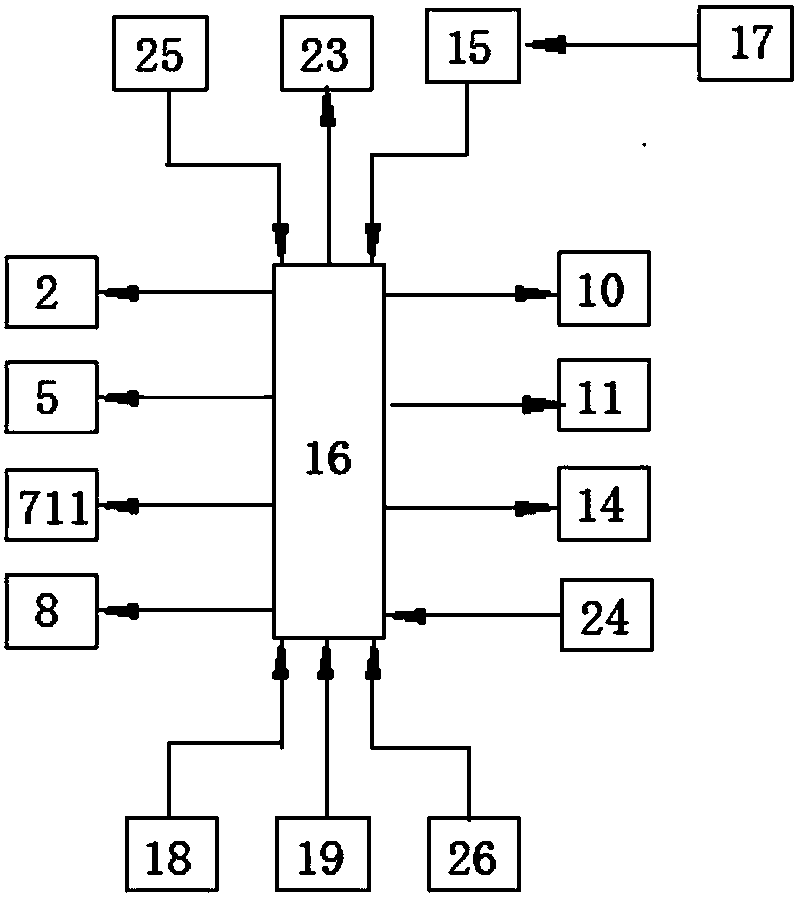

[0037] Embodiment: a kind of intelligent powder mixer, as Figure 1-Figure 3 As shown, it includes a barrel body 1, a stirring device, a temperature control device, a pressure control device and a control panel;

[0038] The upper end of the barrel has a feed port 1-1 and the lower end has a discharge port 1-2;

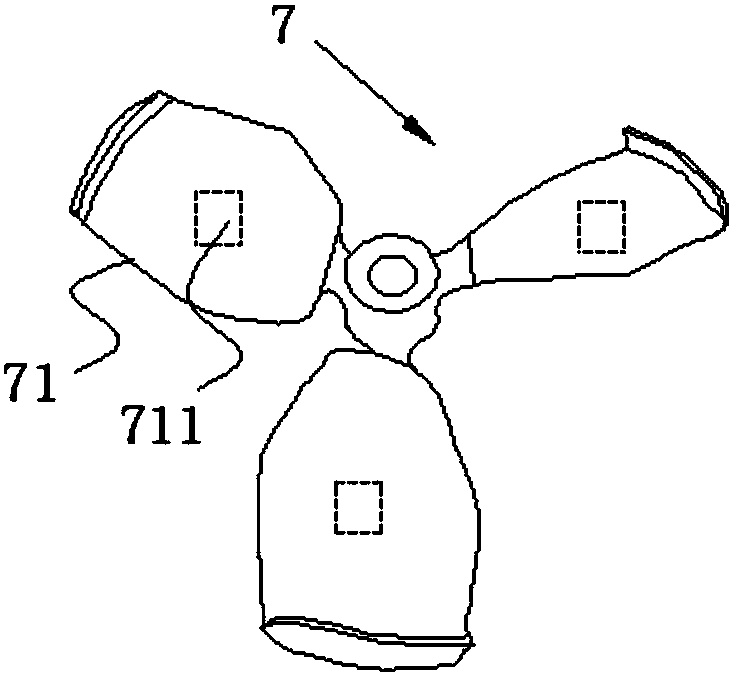

[0039] The stirring device comprises a first driving motor 2, a moving wheel 3 sleeved on the output shaft of the first driving motor, a briquetting block 4, a second driving motor 5 and a stirring shaft 6, and the first driving motor 2 is fixed On the rear side wall of the barrel body 1, both ends of the briquetting block 4 are fixedly connected to the inner wall of the upper end of the barrel body through elastic connectors, the moving wheel 3 is attached to the upper surface of the briquetting block 4, and the The second driving motor 5 is fixed on the lower surface of the briquetting block 4, the upper end of the stirring shaft 6 is fixedly connected with the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com