Hard box cigarette packer lining paper surface oiling device

A technology of oiling device and inner lining paper, which is applied to the device for coating liquid on the surface, packaging cigarettes, coating, etc., which can solve the problem of unstable spraying affecting the quality of inner lining paper packaging, high maintenance cost of precision nozzle structure, and equipment Problems such as normal operation are greatly affected, so as to ensure the quality of folding packaging, avoid contact with felt for a long time, and avoid excessive oil immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

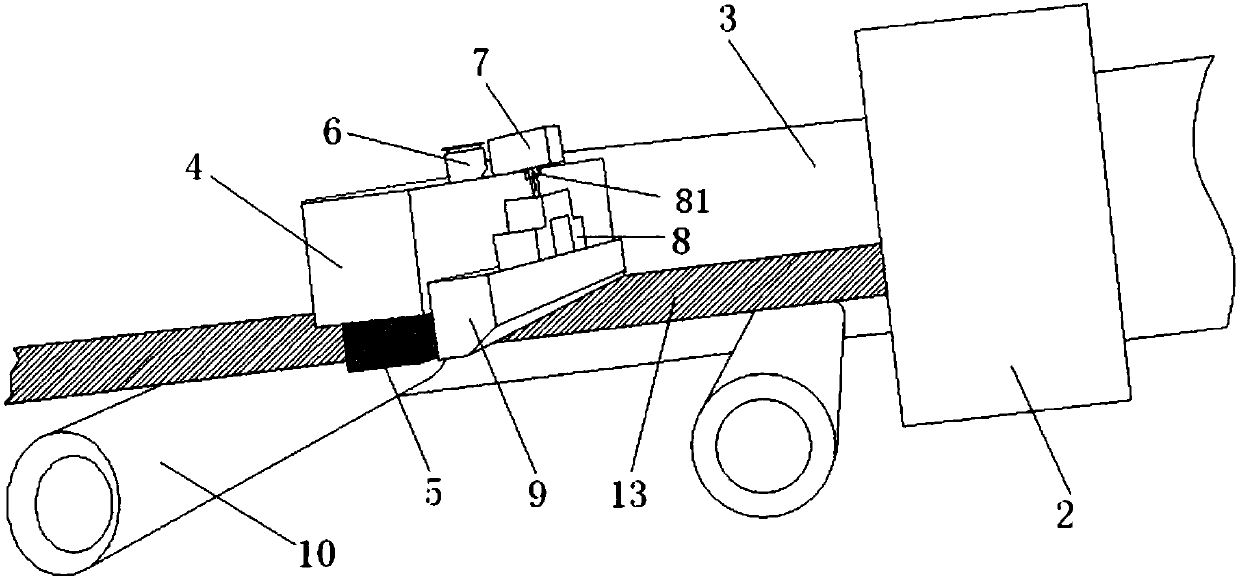

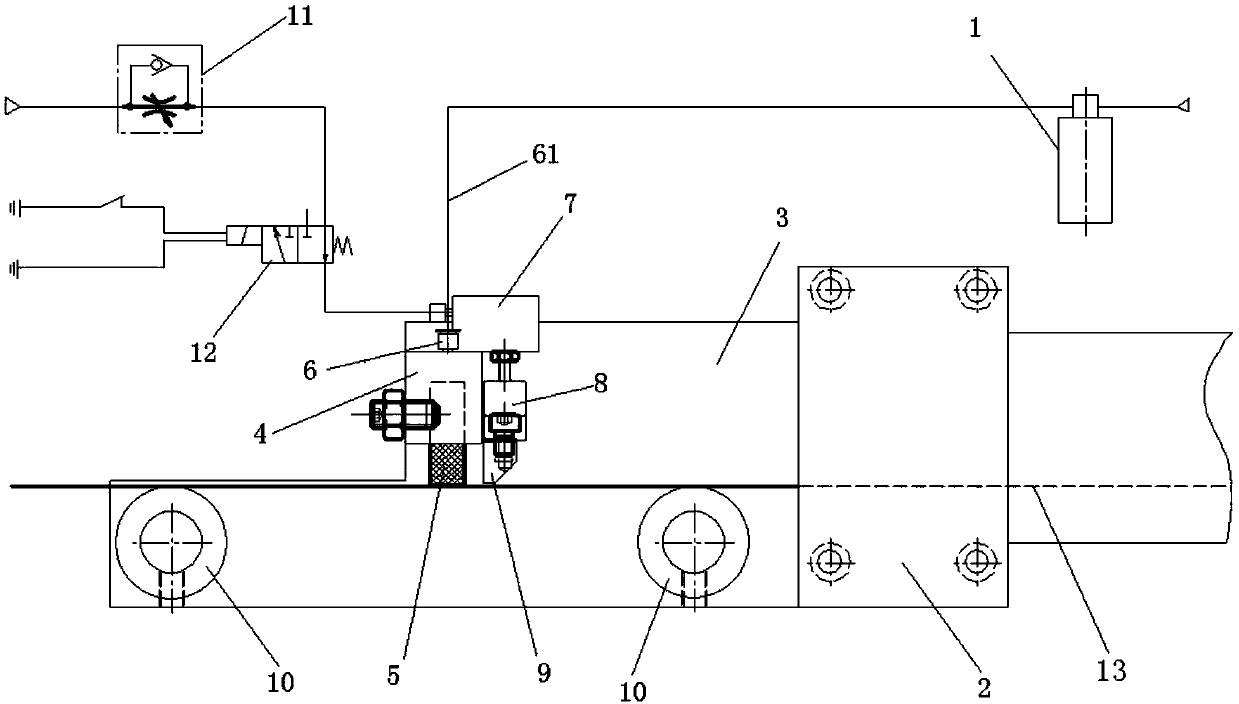

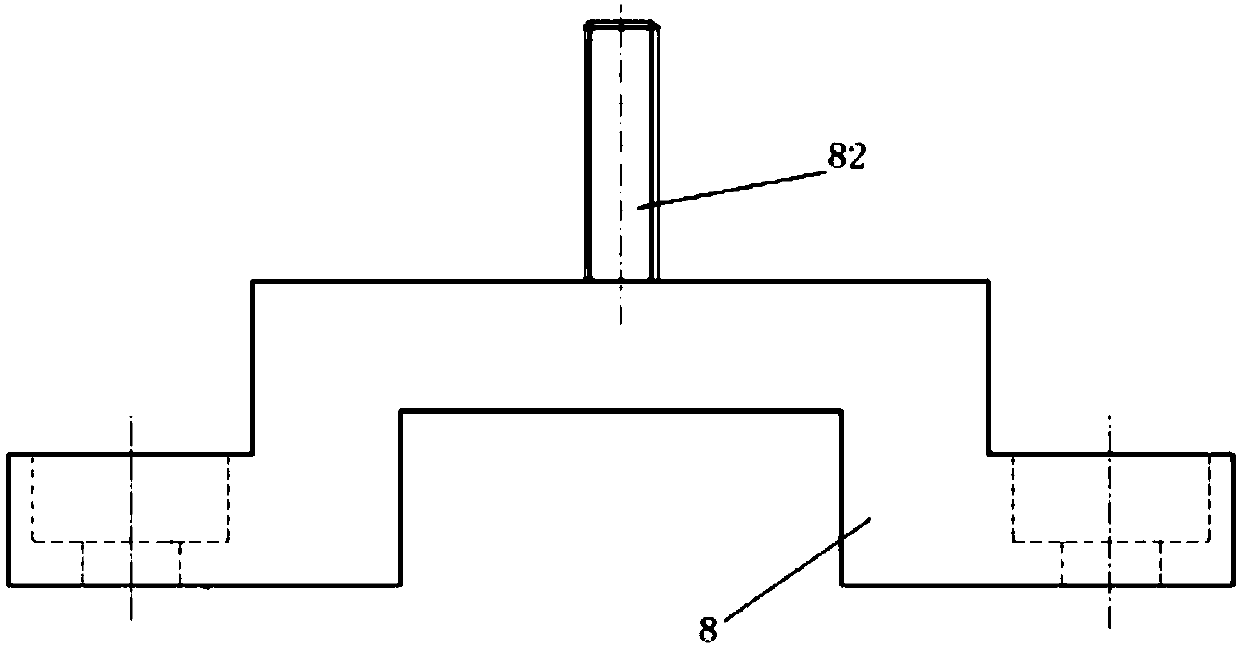

[0025] See Figure 1 to Figure 4 This embodiment discloses an oiling device for the inner liner paper surface of a hard box cigarette packaging machine. The hard box cigarette packaging machine includes a small box packaging machine. The small box packaging machine includes a paraffin storage tank 1, an inner lined paper conveying guide 2. An oiling device is provided on the inner liner paper conveying guide. The oiling device includes a mounting plate 3, two supporting rollers 10, an oiling bracket 4, a felt 5, a cylinder 7, a separating pressure plate 9, and the mounting plate 3 is installed on the inner liner. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com