Chip polishing device for data cable manufacturing factory

A polishing device and a technology of a manufacturing plant, which are applied in the direction of manufacturing tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of poor polishing effect and low polishing efficiency, and achieve the effect of reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

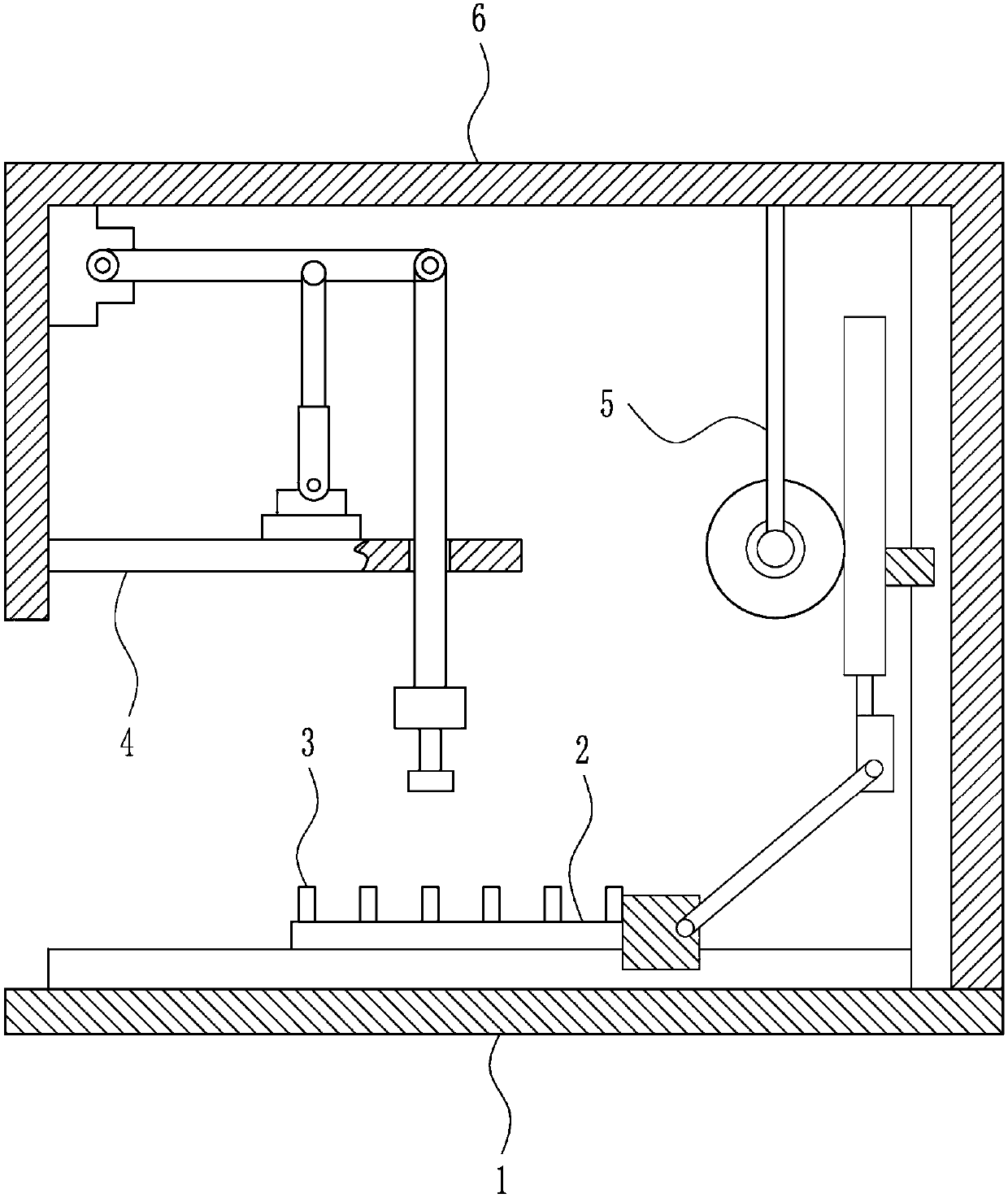

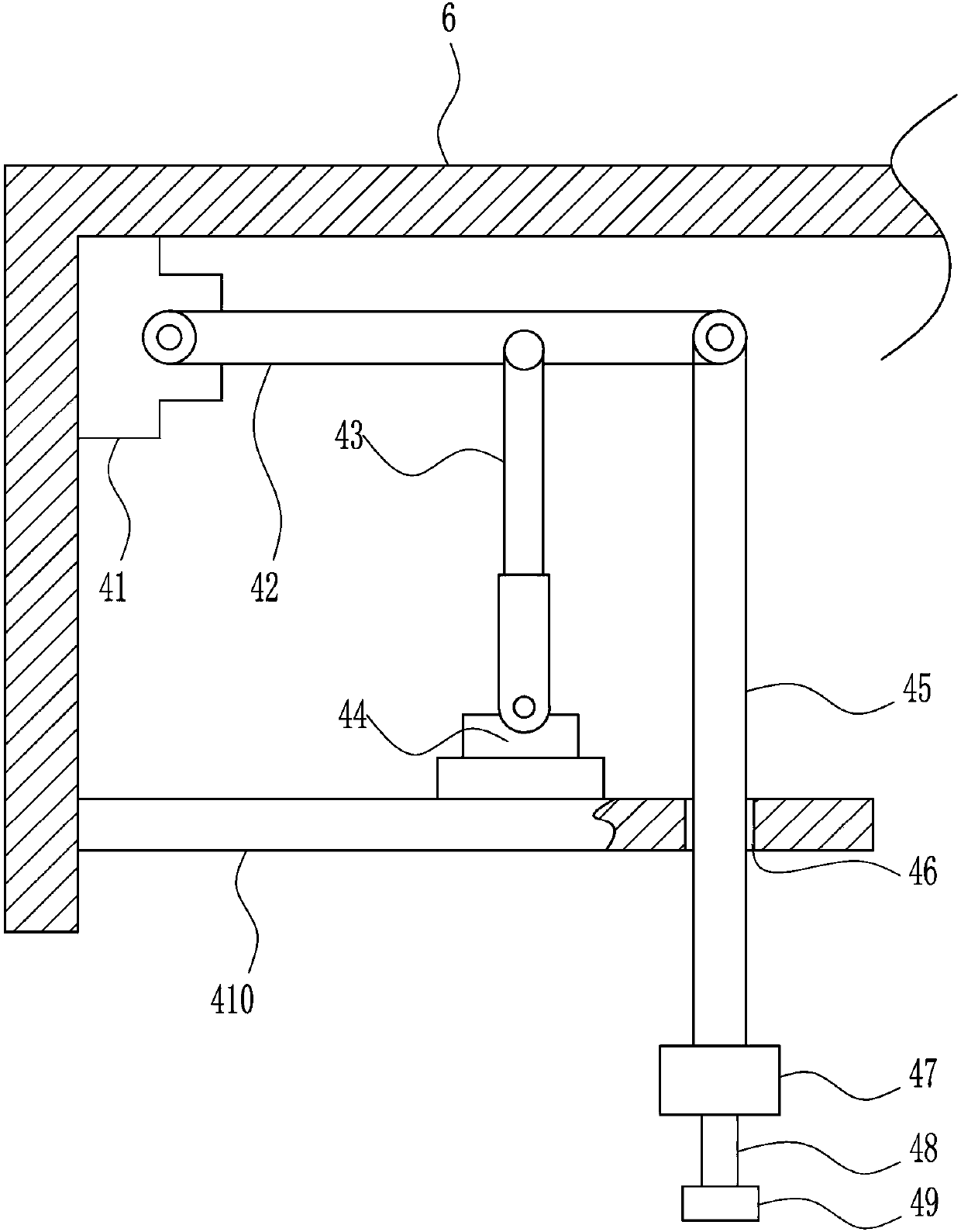

[0028] A chip polishing device for a data line manufacturing plant, such as Figure 1-5 As shown, it includes a bottom plate 1, a storage box 2, a baffle plate 3, a polishing mechanism 4, a left and right moving mechanism 5 and a mounting frame 6; the mounting frame 6 is fixed on the top of the bottom plate 1; Between the bottom plate 1, it is used to adjust the horizontal position of the chip; the storage box 2 is fixedly connected to the output end of the left and right moving mechanism 5, and the baffle plate 3 is fixedly connected to the top of the storage box 2 at equal intervals; the polishing mechanism 4 is fixedly connected to the inner wall of the installation frame 6 , and the output end of the polishing mechanism 4 is located above the placement box 2 for polishing the chip.

Embodiment 2

[0030] A chip polishing device for a data line manufacturing plant, such as Figure 1-5 As shown, it includes a bottom plate 1, a storage box 2, a baffle plate 3, a polishing mechanism 4, a left and right moving mechanism 5 and a mounting frame 6; the mounting frame 6 is fixed on the top of the bottom plate 1; Between the bottom plate 1, it is used to adjust the horizontal position of the chip; the storage box 2 is fixedly connected to the output end of the left and right moving mechanism 5, and the baffle plate 3 is fixedly connected to the top of the storage box 2 at equal intervals; the polishing mechanism 4 is fixedly connected to the inner wall of the installation frame 6 , and the output end of the polishing mechanism 4 is located above the placement box 2 for polishing the chip.

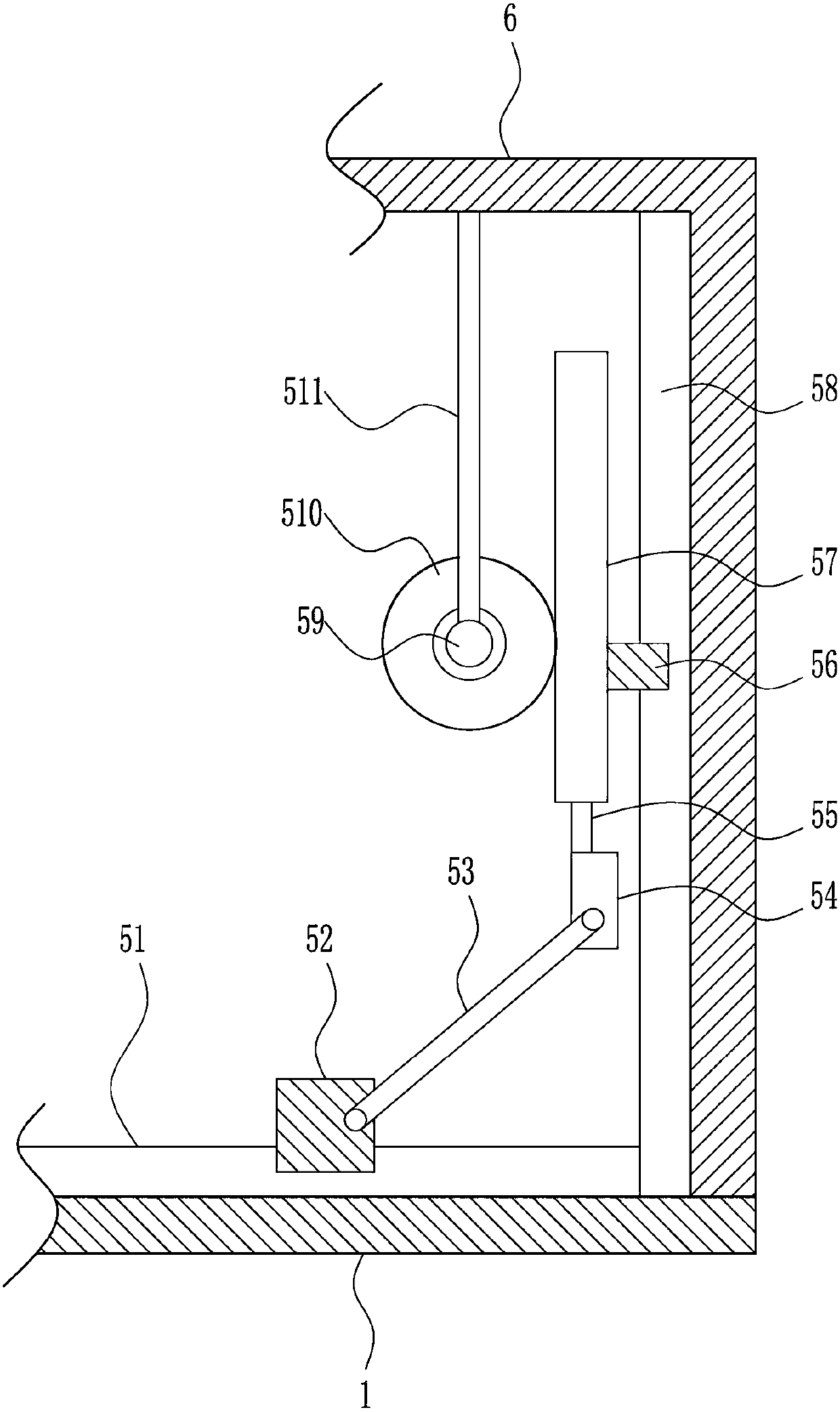

[0031]The left and right moving mechanism 5 includes a first slide rail 51, a first slide block 52, a connecting rod 53, a fixed block 54, a first pole 55, a second slide block 56, a rack 57, ...

Embodiment 3

[0033] A chip polishing device for a data line manufacturing plant, such as Figure 1-5 As shown, it includes a bottom plate 1, a storage box 2, a baffle plate 3, a polishing mechanism 4, a left and right moving mechanism 5 and a mounting frame 6; the mounting frame 6 is fixed on the top of the bottom plate 1; Between the bottom plate 1, it is used to adjust the horizontal position of the chip; the storage box 2 is fixedly connected to the output end of the left and right moving mechanism 5, and the baffle plate 3 is fixedly connected to the top of the storage box 2 at equal intervals; the polishing mechanism 4 is fixedly connected to the inner wall of the installation frame 6 , and the output end of the polishing mechanism 4 is located above the placement box 2 for polishing the chip.

[0034] The left and right moving mechanism 5 includes a first slide rail 51, a first slide block 52, a connecting rod 53, a fixed block 54, a first pole 55, a second slide block 56, a rack 57,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com