Clamping head structure used for industrial robot

A technology of industrial robots and base plates, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of inconvenient disassembly and maintenance of the structure of the chucking head, inconvenient use of various workpieces, and easy side sliding of the workpieces, so as to achieve convenient installation and push. Rod and fixed block, simple structure, easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

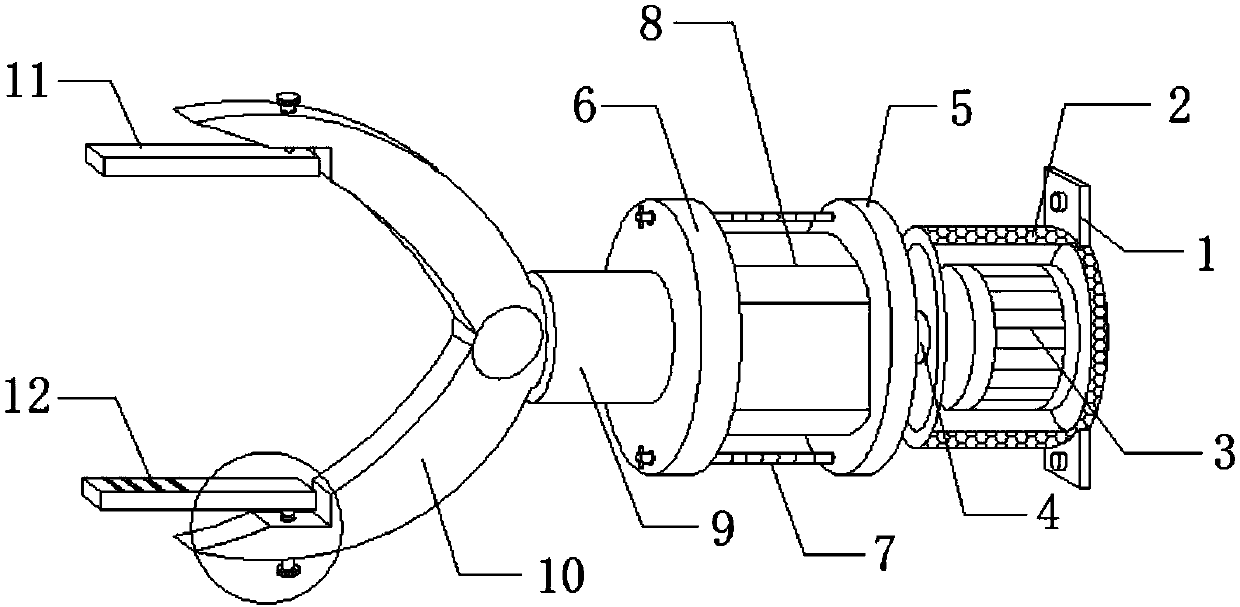

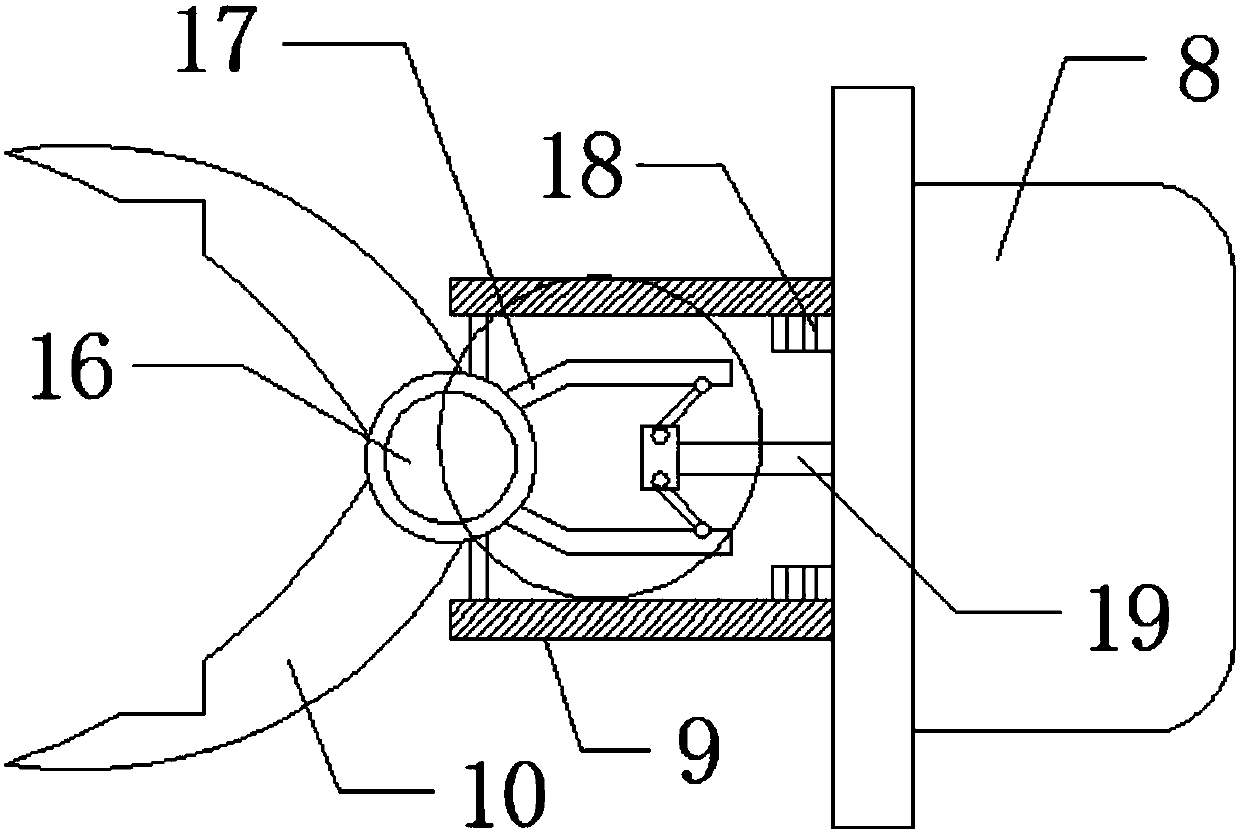

[0023] see Figure 1-4 As shown, a clamping head structure for an industrial robot includes a mounting plate 1 and a clamping claw 10. The mounting plate 1 is the connecting part of the device installed on the body of the industrial robot. A heat dissipation cover 2 is provided on one side of the mounting plate 1. , the motor 3 is installed inside the cooling cover 2, the heat generated by the motor 3 is dissipated from the cooling cover 2, the top of the motor 3 is provided with a rotating rod 4, and one end of the rotating rod 4 is provided with a base plate 5, and the top of the base plate 5 is installed with a hydraulic pressure The pump 8, the top of the hydraulic pump 8 is provided with a top plate 6, two screw rods 7 are installed between the bottom plate 5 and the top plate 6, a sleeve 9 is installed on one side of the top plate 6, a threaded joint 18 is provided at one end of the sleeve 9, and the other end of the sleeve 9 One end is provided with a turntable 16, and ...

Embodiment 2

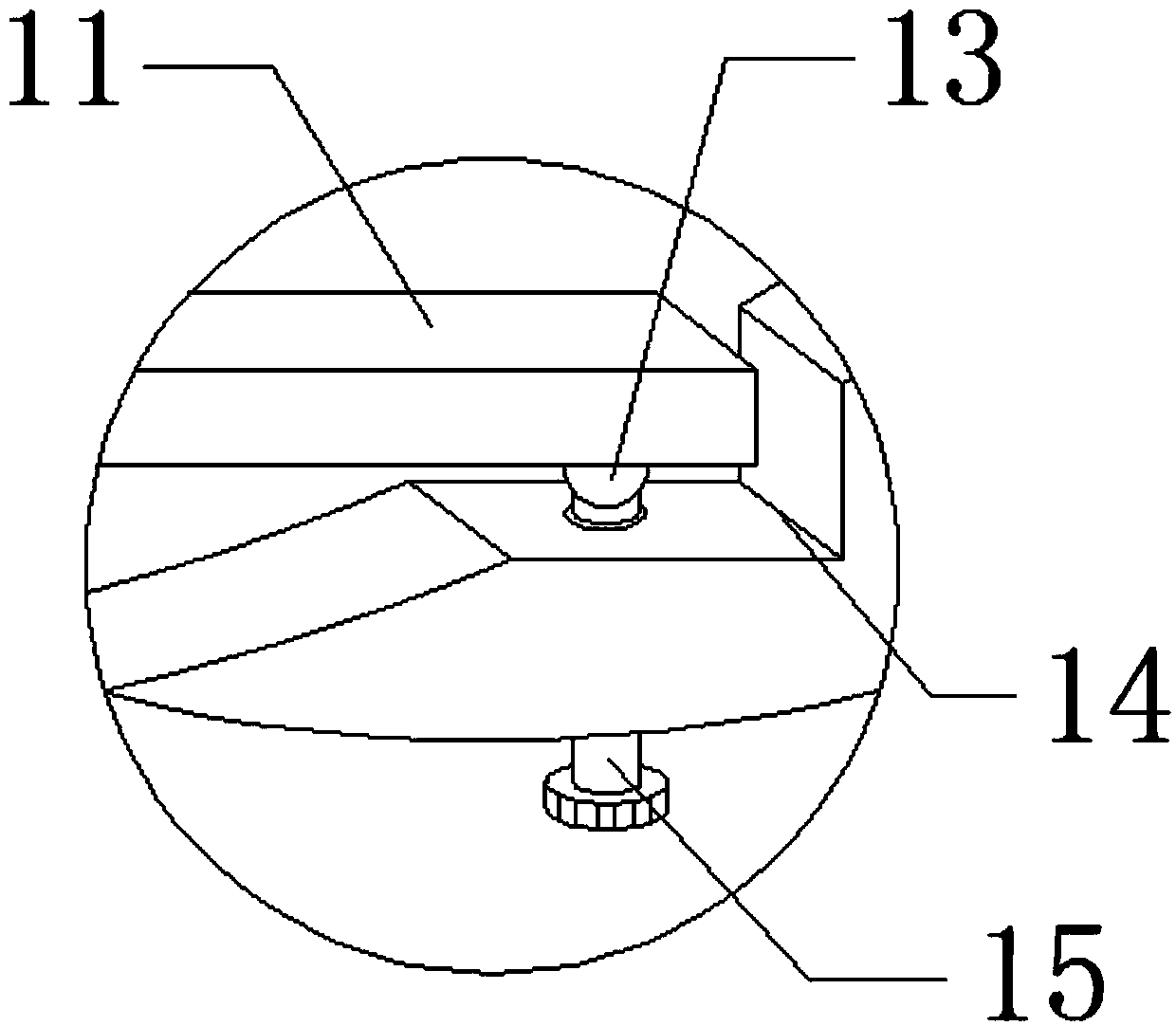

[0025] In addition, refer to Figure 1-4 , different from the above-mentioned embodiment 1, the movable rod 11 is provided with several rubber strips 12 at the end far away from the clamping jaw 10, and the two groups of rubber strips 12 are arranged symmetrically, so that the movable rod 11 can be used to clamp large volume the workpiece, and the rubber strip 12 increases the friction between the movable rod 11 and the workpiece to prevent the workpiece from falling. Rotate the connection, so that the adjusting bolt 15 can be rotated from the outside of the clamping claw 10 to rotate the movable rod 11 to a position perpendicular to the clamping claw 10, and the tip of the clamping claw 10 is used for workpiece clamping, and the two ends of the connecting rod 21 Rotating shafts 22 are arranged at both ends, and the connecting rod 21 is rotationally connected with the fixed block 20 and the control handle 17 through the rotating shaft 22, so that the connecting rod 21 can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com