Drying box wind nozzle for colored coating

A tuyere and oven technology, which can be applied to devices for applying liquid to surfaces, coatings, pre-treatment surfaces, etc., and can solve problems such as shadows on the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

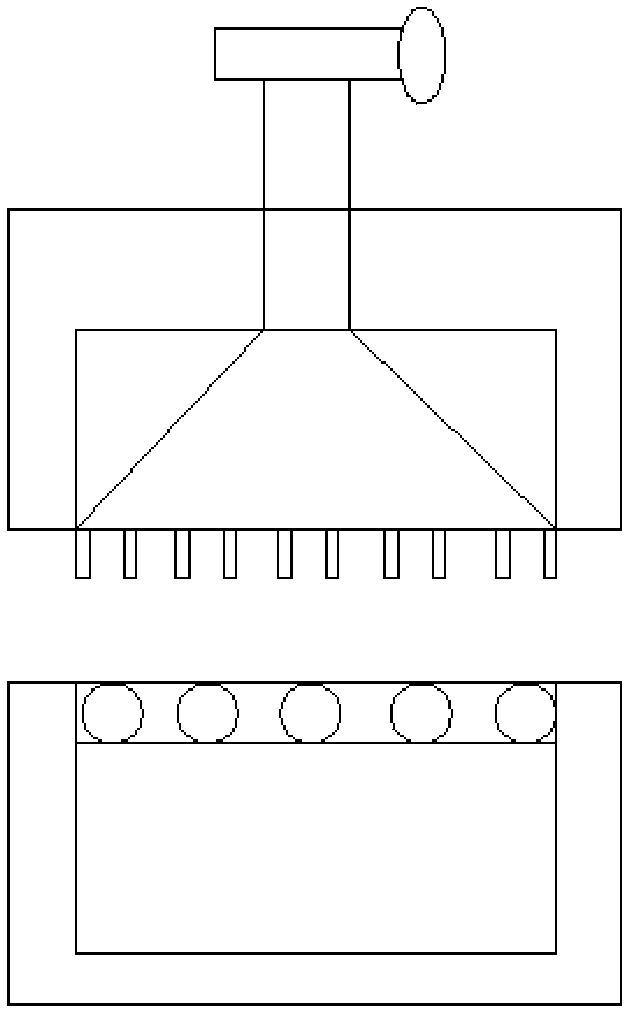

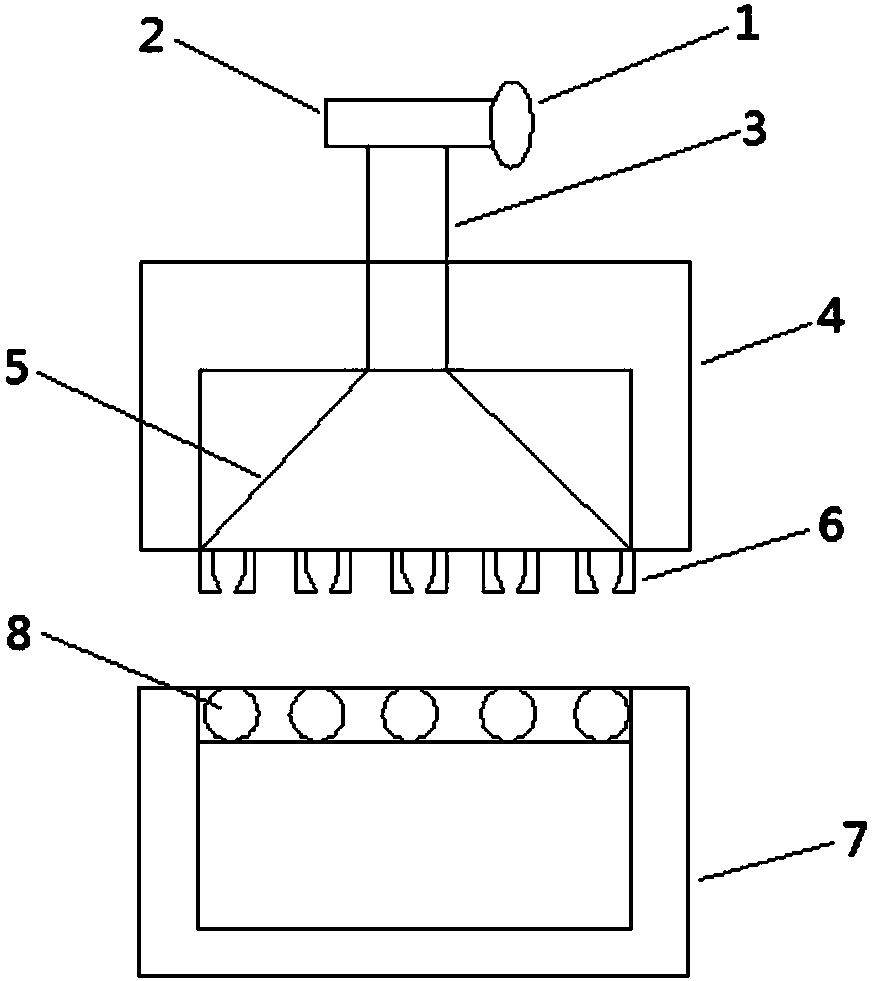

[0033] See image 3 with Figure 4 , A schematic diagram of the structure of an oven and a schematic diagram of the structure of an oven nozzle.

[0034] This embodiment provides an oven air nozzle for colored coating, including: upper shell 4, fan 1, heating pack 2, ventilation duct 3, positive pressure cavity 5, air nozzle 6, lower shell 7 and guide Round 8

[0035] The heating pack 2 is provided between the fan 1 and the ventilation duct 3;

[0036] The ventilation duct 3 has a hollow structure and is arranged above the upper casing 4 and communicates with the upper casing 4;

[0037] The inside of the upper housing 4 is provided with the positive pressure cavity 5 communicating with the ventilation duct 3;

[0038] A number of the air nozzles 6 are provided at the lower end of the positive pressure cavity 5;

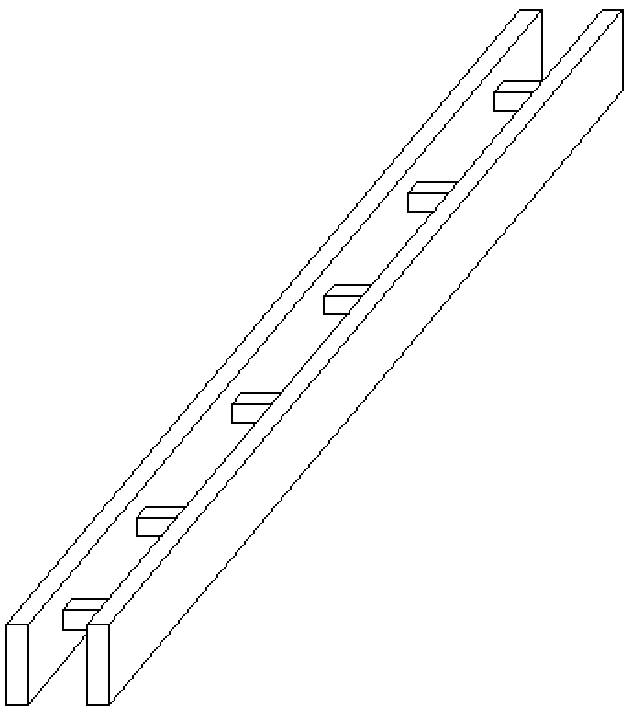

[0039] The air nozzle 6 is provided with openings on the side in contact with the positive pressure cavity 5 and the opposite side, and each of the air nozzles 6 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com