Automatic bag manufacturing production line

A production line and automatic production technology, which is applied in bag making, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of insufficient glue amount of paper tape, increase of production cost, overflow, etc., so as to improve the degree of automation and save production Effects of cost and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

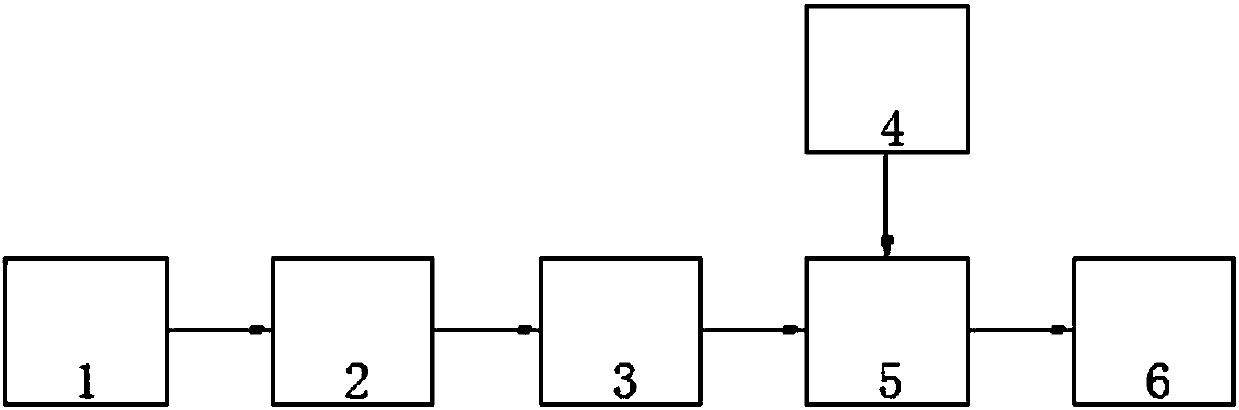

[0055] Embodiment: a kind of automatic bag making production line, as Figure 1-Figure 12 As shown, it includes a flexible printing device 1, a cutting device 2, a bag body forming device 3, a handle machine 4, a gluing forming device 5 and a press machine 6. According to the manufacturing process of the handbag, the flexible printing device 1 is located at the The upstream of the cutting device 2, the cutting device 2 is located at the upstream of the bag forming device 3, and the bag forming device 3 and the handle machine 4 are located at the side of the gluing forming device 5. Upstream, the gluing forming device 5 is located upstream of the press 6;

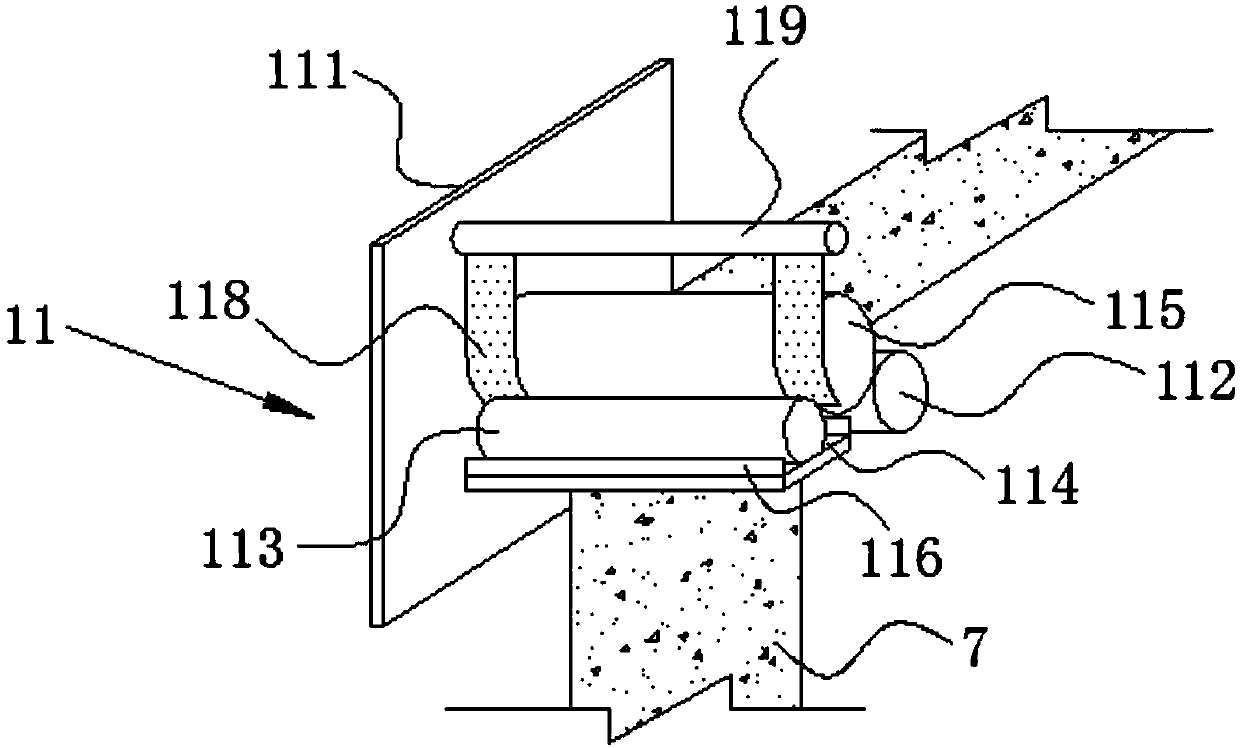

[0056] The flexible printing device 1 includes a feeding mechanism, several printing mechanisms 11 and a retracting mechanism, the discharging mechanism is located upstream of the printing mechanism 11, and the printing mechanism 11 is located upstream of the retracting mechanism;

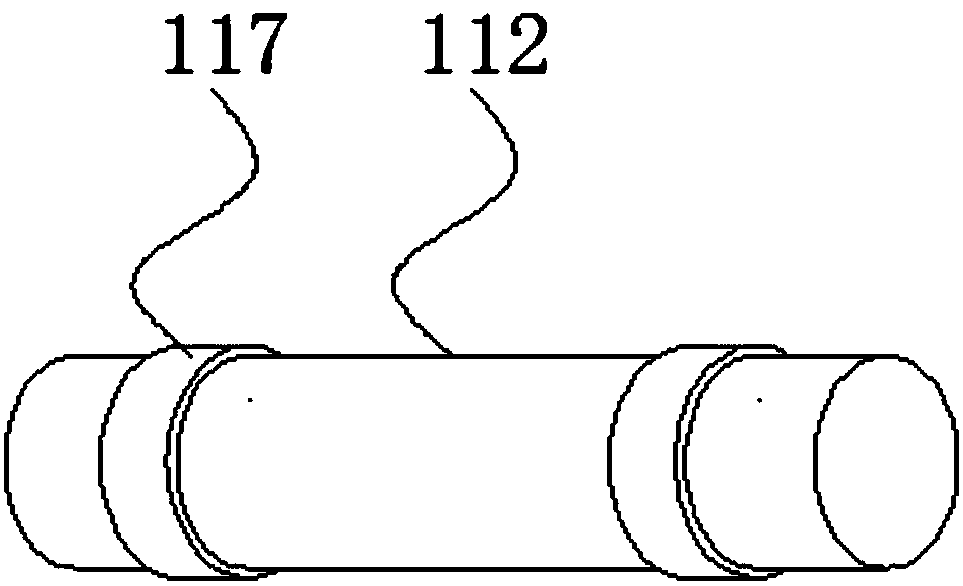

[0057] Described printing mechanism 11 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Arc length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com