Cable marker printing and conveying device

A technology for conveying devices and number tubes, which is applied to printing devices, printing, typewriters, etc., can solve the problems of printer damage, number tube twisting, etc., and achieve the effects of simple operation, elimination of winding, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

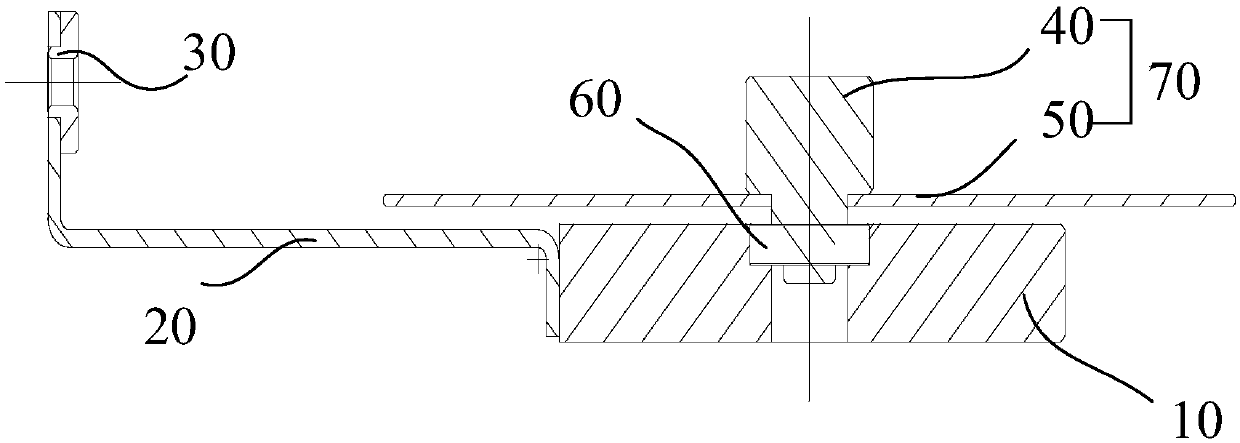

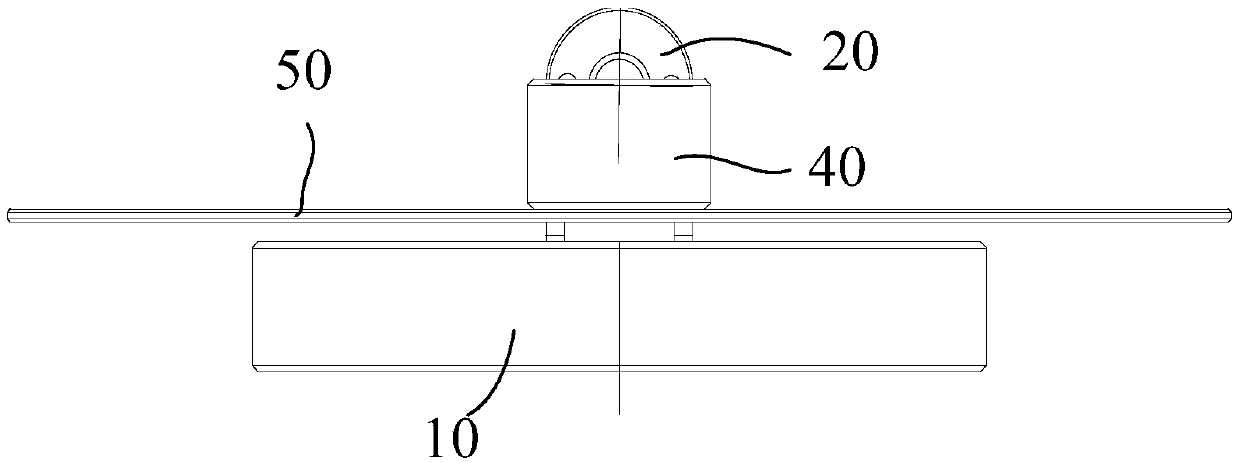

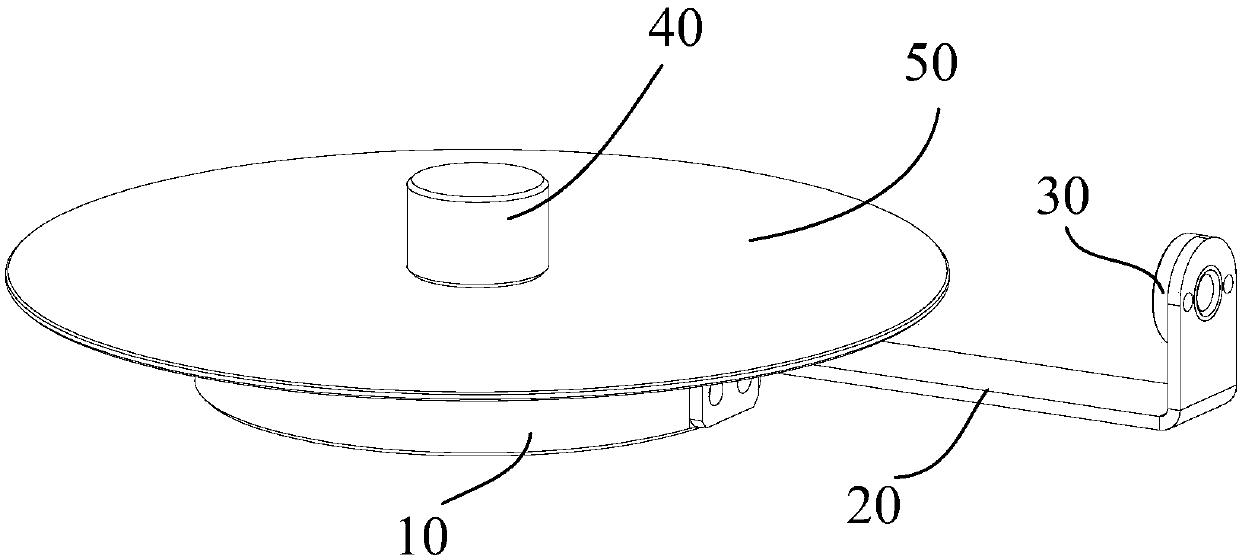

[0039] Such as Figures 1 to 10 As shown, a number tube printing and conveying device in this embodiment includes a base 10, a rotating assembly 70, a guide plate 20 and a guide sleeve 30. Preferably, the base 10, the rotating assembly 70 and the guide plate 20 are all made of stainless steel, and the base 10 is placed horizontally, the middle part of the base 10 is provided with a through hole in the vertical direction, one end of the rotating assembly 70 is located in the through hole, and is connected to the base 10 in rotation, one end of the guide plate 20 and the side of the base 10 are connected by bolts, and the other One end is fixed with a guide sleeve 30 through bolt connection, and a guide hole 31 for conveying number tubes is processed on the guide sleeve 30 , and the guide sleeve 30 and the rotating assembly 70 are located on the same side of the base 10 .

[0040] The rotating assembly 70 in this embodiment includes a rotating shaft 40 and a supporting plate 50....

Embodiment 2

[0054] This embodiment has all the technical features in Embodiment 1, and the difference from Embodiment 1 is that the second connecting plate 21 of the guide plate 20 of a kind of number tube printing conveying device in this embodiment is designed to be scalable in the horizontal direction The structure, and the telescopic structure has a locking device.

[0055] The adjustment process of the guide plate 20 of the present embodiment is as follows: when the number tubes wound around the number tube roller in the radial direction are less sharply, turn off the number tube printer, adjust the flexible second connecting plate 21, and move the third connecting plate 27 After adjusting and fixing the number tube wound on the guide sleeve 30 and the number tube roller in the direction of the axis of the rotating shaft 40 at a suitable distance, open the number tube printer and continue the printing work of the number tube.

[0056] The beneficial effect of this embodiment is that ...

Embodiment 3

[0058] This implementation has all the features of Embodiment 1, the difference is that a number tube printing and conveying device in this embodiment also includes a servo motor, a shaft coupling and a control host, and the third shaft section 43 of the rotating shaft 40 is passed through the connecting shaft. The servo motor is installed on the output shaft of the servo motor, and the servo motor is fixed on the lower end of the base 10 through bolt connection, and a shock-absorbing bracket is installed at the contact end between the servo motor and the ground, and the servo motor and the number tube printer are connected to the control host , the control host controls the rotation of the servo motor in real time according to the printing speed of the number tube printer.

[0059] The beneficial effect of this embodiment is: by installing the servo motor to drive the number tube roller to rotate, the conveying speed of the number tube via the guide sleeve 30 can be adjusted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com