Preparation method for joint production of 3,3,3-trifluoro-1,2-propanediol and 4-trifluoromethylethylene carbonate

A technology of trifluoromethyl ethylene carbonate and propylene glycol is applied in the field of preparation of fluorine-containing alcohol and fluorine-containing five-membered cyclic carbonate, and can solve the problems of harsh reaction conditions, complex reaction system, low reaction efficiency, etc. Mild conditions, good atom economy, and high reaction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of co-production TFPG and TFPC provided by the present invention comprises the following steps: taking 3,3,3-trifluoropropylene oxide as raw material, reacting with carbon dioxide in the presence of hydrogen halide solution and organic base, the reaction temperature 70°C-180°C, reaction pressure 0.1MPa-5MPa, after the reaction is completed, the obtained crude 3,3,3-trifluoro-1,2-propanediol and 4-trifluoromethylethylene carbonate are separated and purified Target products TFPG and TFPC.

[0021]The hydrogen halide solution in the present invention is one or more combinations of hydrogen iodide solution, hydrogen bromide solution, hydrogen chloride solution or hydrogen fluoride solution, preferably commercially available hydroiodic acid with a mass percentage of 55%-58%, and a mass percentage of 48% One or more combinations of hydrobromic acid, hydrochloric acid of 36-38% by mass percent, hydrofluoric acid of 40% by mass percent; among the present ...

Embodiment 1

[0030] Add 3,3,3-trifluoropropylene oxide (0.3mol), 48% HBr solution (15mmol), triethylamine (15mmol) successively into a 50mL stainless steel autoclave equipped with stirring, and use CO 2 Replace the reactor twice, start stirring and heat to 100°C, and continuously feed CO 2 Keep the reaction pressure at 0.5MPa, react for 4h, then cool to room temperature, slowly release excess CO 2 gas, 3,3,3-trifluoro-1,2-propanediol and 4-trifluoromethylethylene carbonate crude products were obtained, and the product distribution was analyzed by gas chromatography, wherein the contents of TFPG and TFPC were 21.2% and 78.4%, respectively. 44.3 g of the target product 3,3,3-trifluoro-1,2-propanediol and 4-trifluoromethylethylene carbonate were obtained, and the calculated yield was 98.7%. The reaction results are shown in Table 1.

[0031] Gas chromatography analysis conditions: Agilent 7820 gas chromatography, hydrogen flame ionization detector, DB-5 capillary column (30m×0.320mm×0.25μm),...

Embodiment 2-11

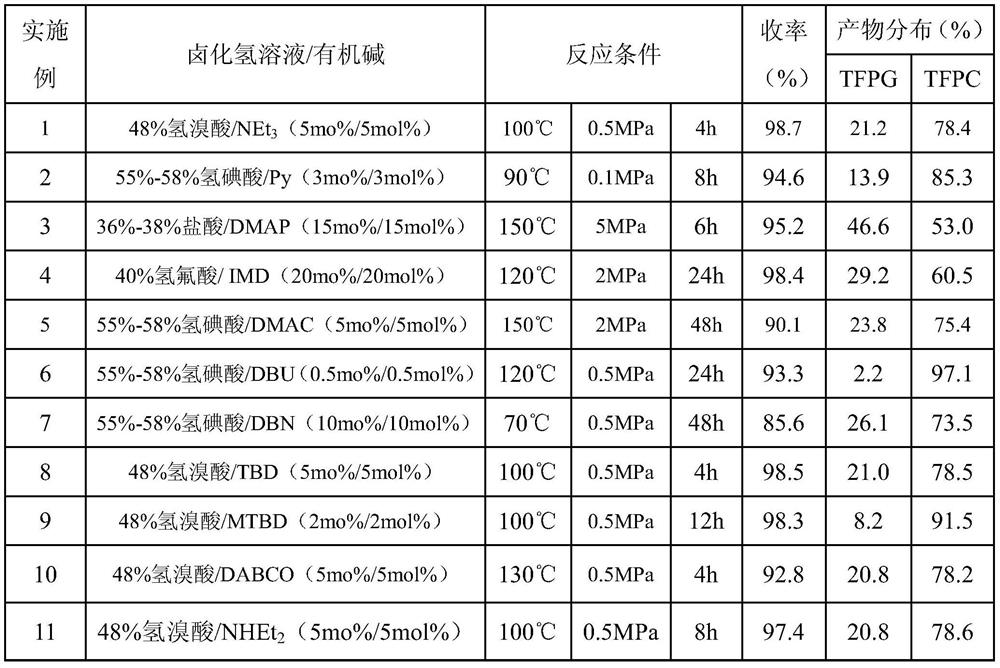

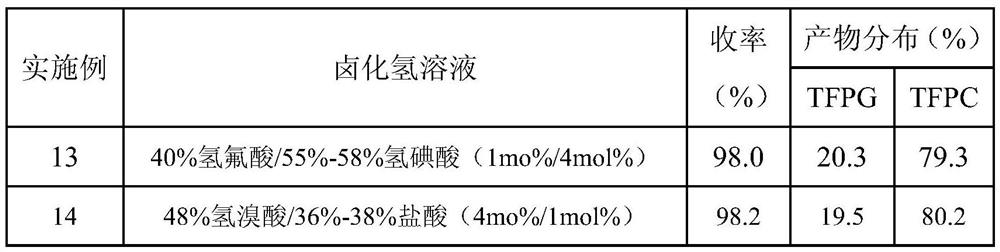

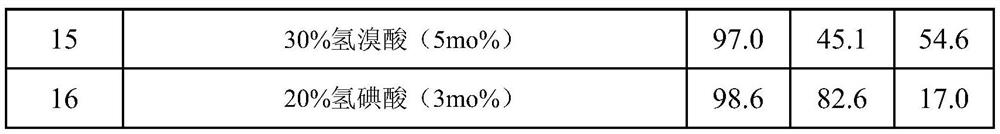

[0033] Embodiment 2~11 is reacted according to the same method in embodiment 1, and conditions such as the hydrogen halide solution that it adopts, organic base, reaction temperature, reaction pressure, reaction time and corresponding reaction result, product distribution are as shown in table 1 .

[0034] Table 1

[0035]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap