Sewage pipeline cleaning device

A technology for cleaning devices and sewage pipes, applied to water supply devices, cleaning sewer pipes, waterway systems, etc., can solve problems such as difficult work, secondary pollution, difficult long-term operation, etc., to avoid difficult cleaning and efficient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

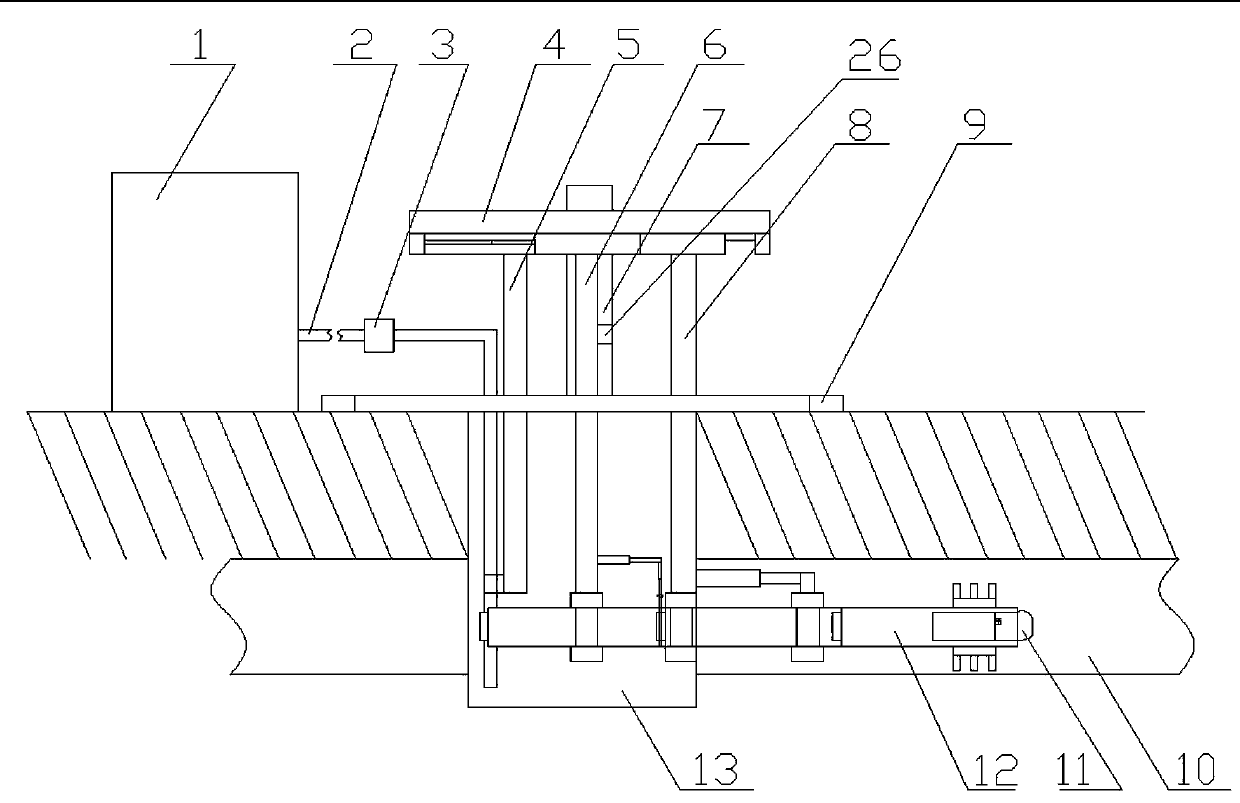

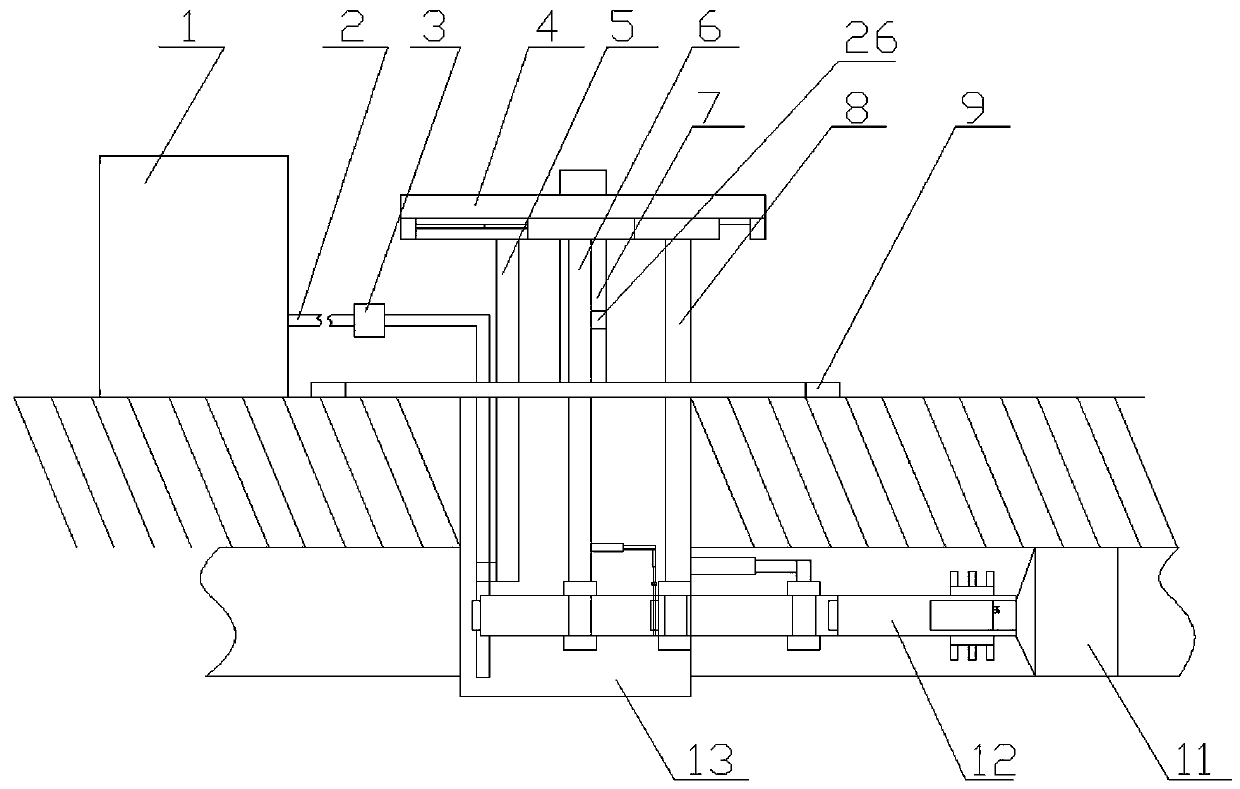

[0050] A device for cleaning sewage pipes, comprising a support mechanism arranged on the ground of a shaft 13, a dredging mechanism arranged on the support mechanism for cleaning sludge, a propulsion mechanism arranged on the support mechanism, and a propulsion mechanism arranged on the A collection mechanism for collecting mud on the propulsion mechanism, a disassembly mechanism arranged on the support mechanism for matching with the propulsion mechanism, and a disassembly mechanism arranged on the support mechanism for controlling the support mechanism, The control mechanism that cooperates with the dredging mechanism, the propulsion mechanism, the collection mechanism and the disassembly mechanism;

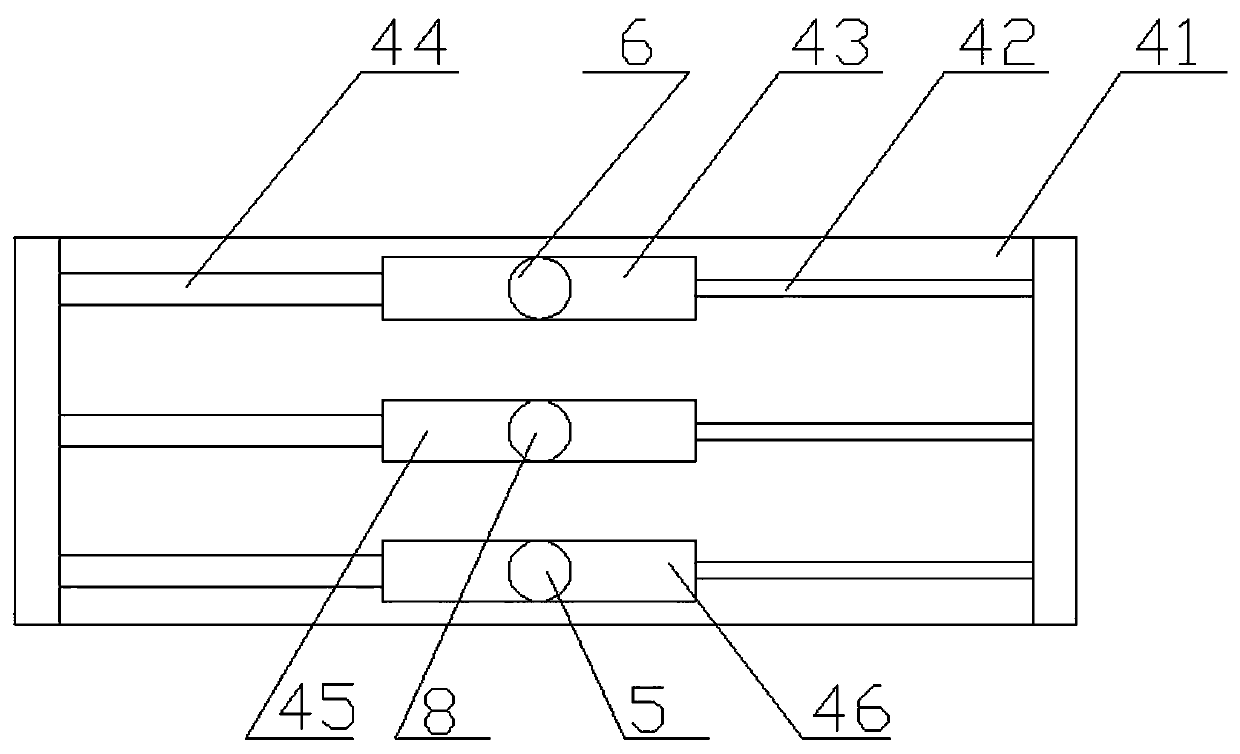

[0051] The support mechanism includes a support base 9 arranged on the ground of the shaft 13, a support column 7 arranged on the support base 9, a support beam 41 arranged on the support column 7, and a support beam 41 arranged on the support column 7. A plurality of walking ...

Embodiment 2

[0065] It differs from Embodiment 1 in that: the gas generator includes a compression tank 16 arranged in the collection tank 25, nitrogen gas arranged in the compression tank 16, and a first electromagnetic pump arranged at the outlet of the compression tank 16 valve 17.

Embodiment 3

[0067] It differs from the second embodiment in that: the supporting base 9 is a ring-shaped supporting base.

[0068] A second electromagnetic valve 20 for exhausting is arranged on the collecting air bag.

[0069] The upper end of the dismountable supporting telescopic arm 6 is arranged on the inverted L-shaped bridge arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com