Sliding shock isolation device with ring beam masonry structure and construction method of sliding shock isolation device

A masonry structure, masonry technology, applied in earthquake resistance, building components, building structure and other directions, can solve problems such as poor earthquake resistance, and achieve the effects of low cost, simple construction and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

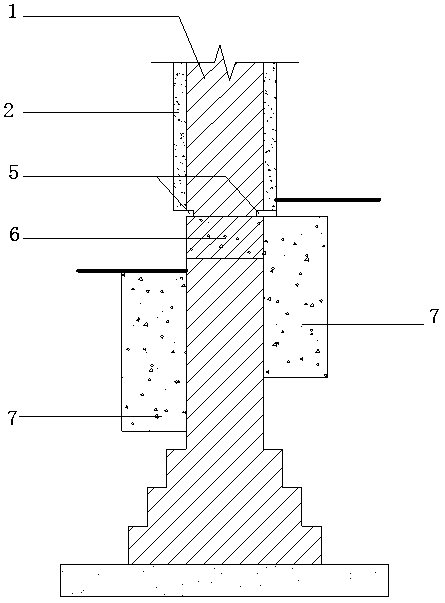

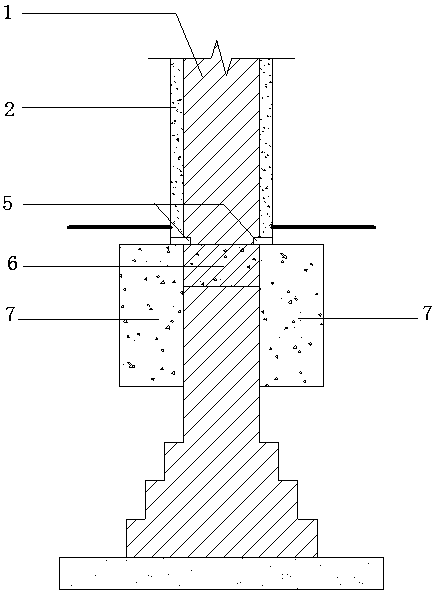

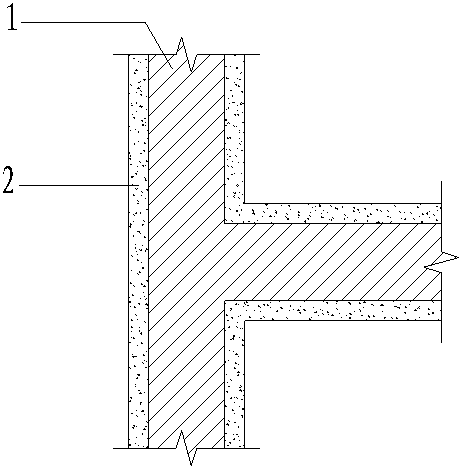

[0041] Such as figure 1 and figure 2 , image 3 , Figure 4 As shown, this embodiment provides a kind of slip isolation device for a masonry structure with ring beam reinforced by high ductility concrete, including the original masonry structure 1, the original masonry structure 1 is provided with a geosphere beam 6, and the geosphere The beam 6 is provided with a weak layer 5, the wall of the original masonry structure 1 above the weak layer 5 is double-sidedly pressed and plastered with a high ductility concrete surface layer 2, and the wall of the original masonry structure 1 below the weak layer 5 is reinforced by pouring on both sides Concrete7. The weak layer 5 is to caulk the 6 mortar joints of the geosphere beam of the original masonry structure 1, and the caulking depth is ≥ 10mm. The original masonry structure 1 is a brick masonry structure with ring beams or a block masonry structure. The thickness of the high ductility concrete surface layer 2 plastered on th...

Embodiment 2

[0048] This embodiment provides a kind of slip isolation device for steel mesh reinforced masonry structure with ring beams, such as Figure 5 and Figure 6 As shown, it includes the original masonry structure 1 and the steel mesh bound on the surface of the original masonry structure 1. The original masonry structure 1 is provided with a geosphere beam 6 below positive and negative zero, and a weak layer 5 is arranged at the geosphere beam 6. The walls of the original masonry structure 1 above the weak layer 5 are plastered with surface layer 2 on both sides, and the walls of the original masonry structure 1 below the weak layer 5 are poured with reinforced concrete 7 on both sides. The weak layer 5 is to caulk the 6 mortar joints of the geosphere beam of the original masonry structure 1, and the caulking depth is ≥ 10mm. Such as Figure 7 , Figure 8 and Figure 9As shown, the steel mesh is composed of vertical steel bars 3, horizontal steel bars 8 and wall-penetrating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com