Embedded-column formwork device and method for constructing fabricated building embedded column by same

A prefabricated, concealed column technology, applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, on-site preparation of building components, etc. The board is prone to problems such as mold explosion, so as to reduce the construction cost, avoid the mold explosion phenomenon, and improve the quality of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

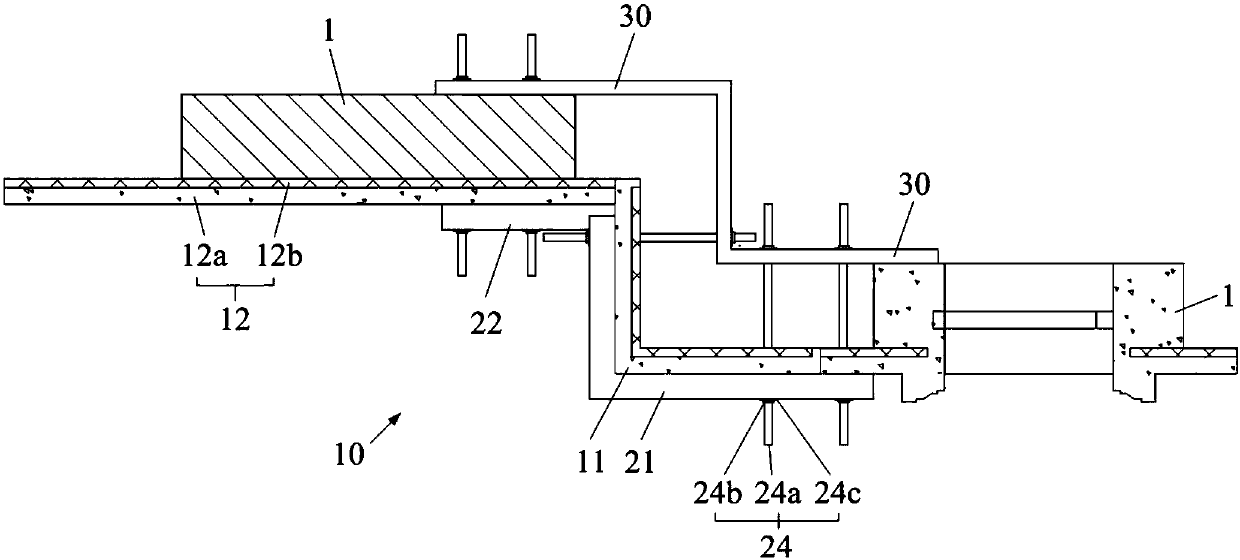

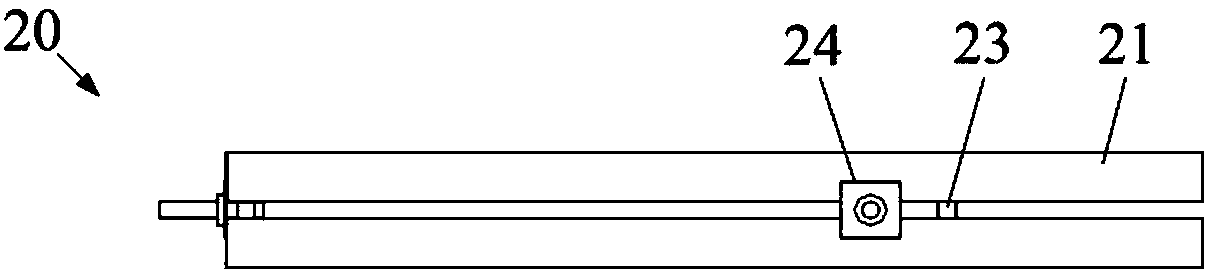

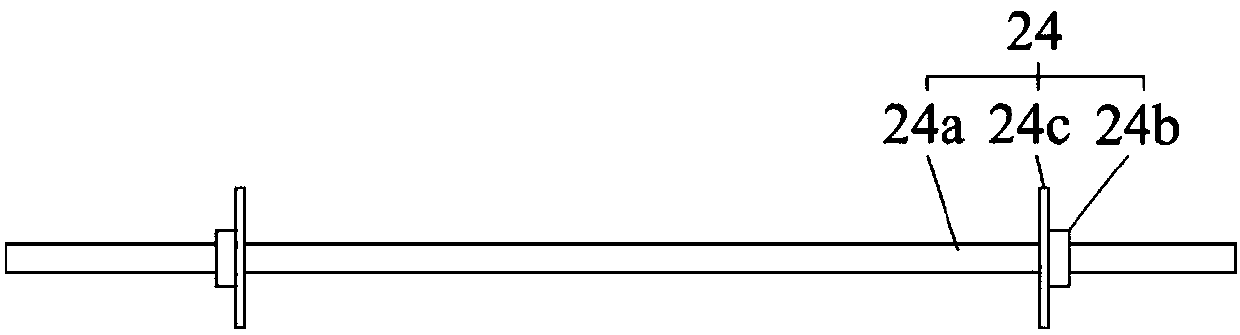

[0031] Example 1: Combining Figure 1 to Figure 4 Illustrate the concealed column formwork device 10 of the present invention, the concealed column 40 of the present embodiment is located at the corners of two adjacent and spaced prefabricated exterior walls 1, and an exterior wall formwork 30 is erected on the outside of the two prefabricated exterior walls 1, and Supported by diagonal braces (not shown in the figure) on the floor surface, the above-mentioned concealed column formwork device 10 includes an L-shaped concealed column panel 11, an I-shaped concealed column panel 12, and a plurality of explosion-proof module assemblies 20, explosion-proof modules Part 20 includes L-shaped reinforcing bar 21, I-shaped reinforcing bar 22 and several connecting pieces 24; figure 1 As shown, the docked L-shaped concealed column panel 11 and I-shaped concealed column panel 12, two adjacent prefabricated exterior walls 1 and exterior wall formwork 30 enclose the area to be poured into ...

Embodiment 2

[0040] Embodiment 2: Different from Embodiment 1, the L-shaped reinforcing rod 21 or I-shaped reinforcing rod 22 of this embodiment is made of a rod with a rectangular cross section, and the L-shaped reinforcing rod 21 or I-shaped reinforcing rod 22 is provided with some bolt holes matched with the pull screw rod 24a of the connector 24, the bolt holes are processed on the reinforcing bar in advance, and the spot is connected with the concealed column panel bolts, which is easy to operate and can realize the technical scheme of the present invention.

Embodiment 3

[0041] Embodiment three: different from embodiment one and embodiment two, such as Figure 5 As shown, the concealed column 40 of this embodiment is located between two prefabricated exterior walls 1 arranged at intervals, rather than at a corner, two I-shaped concealed column panels 12 that are connected, two adjacent prefabricated exterior walls 1, and the exterior Wall formwork 30 surrounds the area to be poured into the concealed column 40, and a plurality of explosion-proof mold assemblies 20 are arranged at intervals along the height direction of the I-shaped concealed column panel 12, such as Figure 6 As shown, after the concrete is cast-in-place and reaches the strength required by the design, the explosion-proof mold assembly 20 is removed to complete the construction of the concealed columns 40 between the prefabricated exterior walls 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com