Device and method for generating turbulent flow by fluids in plastic pipe and adjusting pipe outside flow

A flow adjustment device and flow adjustment technology, applied in the direction of fluid flow, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problems of unsatisfactory fluid uniformity, unfavorable compact equipment structure, accelerated pump wear and aging, etc. , to achieve the effect of improving fluid purity and equipment processing quality, saving space and increasing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

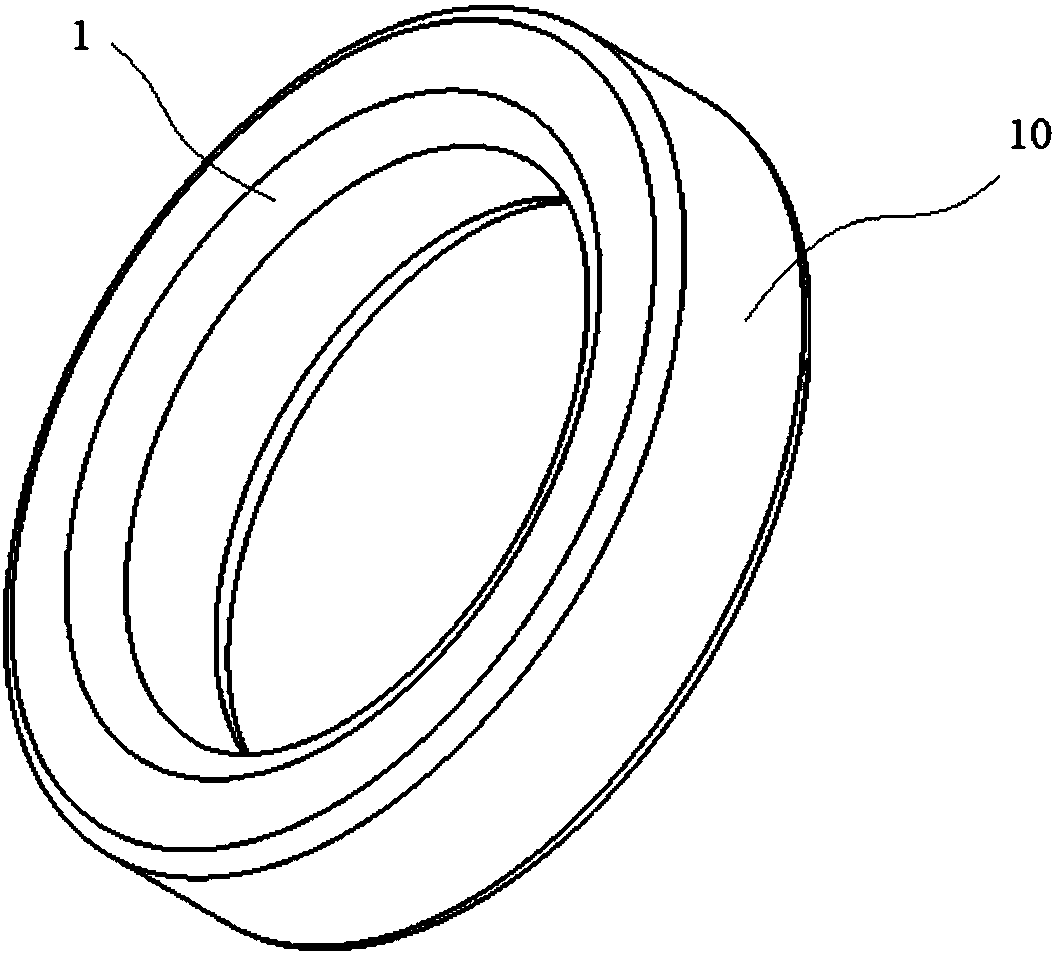

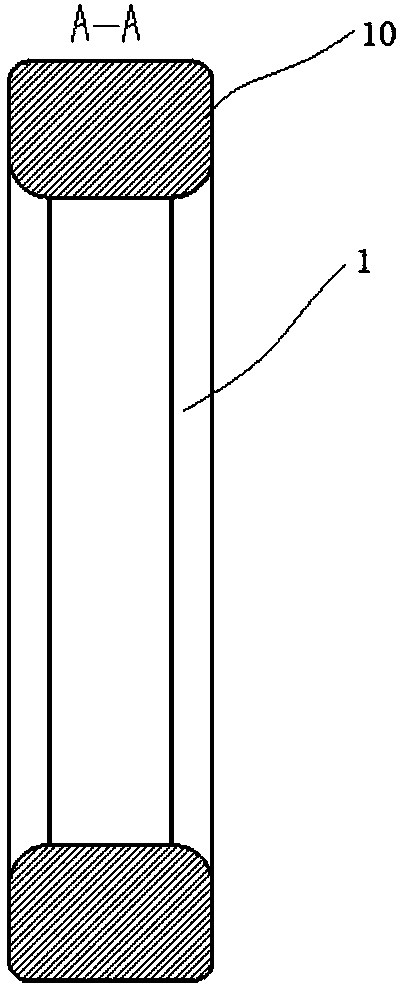

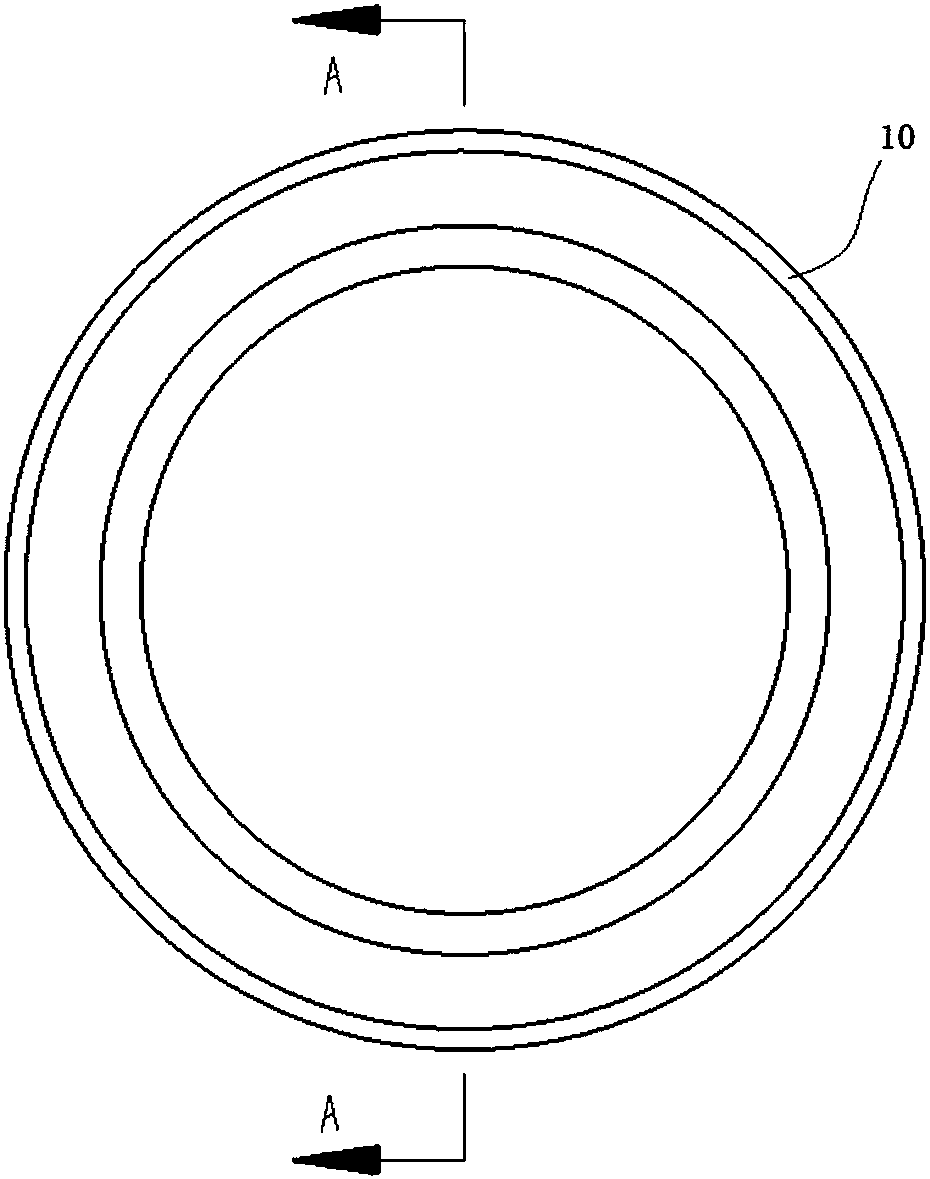

[0047] Embodiment 1: Fluid generates turbulent flow in the plastic pipe and the device and method for regulating the flow outside the pipe, including the extruding device and the plastic pipe 2 . Such as figure 1 , Figure 1a , Figure 1b and Figure 1c As shown, the extrusion device is a sleeve-shaped O-shaped turbulence generation and flow regulating ring 10 made of metal, a circular or oval closed-loop ring, and the two ends of the inner wall are made of smooth arc-shaped chamfers 1, It can be a round chamfer or other smooth arc-shaped chamfers. If the use environment is corrosive, it should be made of anti-corrosion metals such as stainless steel, or coated with anti-corrosion materials on its surface; Figure 4 As shown, put the sleeve-shaped O-shaped turbulent flow generator and flow adjustment ring 10 on the plastic tube 2, squeeze the sleeve-shaped O-shaped turbulent flow generator and flow adjustment ring 10 with pliers or other suitable tools, so that If plastic ...

Embodiment 2

[0048] Embodiment 2: The fluid generates turbulent flow in the plastic tube and the device and method for regulating the flow outside the tube, which includes the extruding device and the plastic tube 2 . Such as Figure 3b As shown, the extrusion device is a bracelet-shaped C-shaped turbulence generation and flow regulating ring 200 made of metal, which is in the above-mentioned image 3 and Figure 3a The O-shaped turbulent flow shown in the bracelet shape has a gap on the basis of the flow adjustment ring 20, such as Figure 3b As shown, the end face of the notch 201 is made with a smooth arc-shaped chamfer 1, which can be a round chamfer or other smooth arc-shaped chamfers; Figure 4 As shown, put the bracelet-shaped C-shaped turbulence generating and flow regulating ring 200 on the plastic tube 2, and squeeze the bracelet-shaped C-shaped turbulent generating and flow regulating ring 200 with pliers or other suitable tools to make it happen. Plastic deformation, after t...

Embodiment 3

[0049] Embodiment 3: The fluid generates turbulent flow in the plastic tube and the device and method for regulating the flow outside the tube, which includes the extruding device and the plastic tube 2 . The extruding device comprises two similar elongated splints 30 with arc-shaped grooves, one side of which is made with arc-shaped grooves 5, and the only difference between the two is that a Figure 5 Both ends of the shown hole 3 are drilled, and the other is shown as Figure 6 Screw holes 4 are drilled at both ends as shown; Figure 9 and Figure 9a As shown, use two screws 31 to connect the two facing elongated splints 30 with arc-shaped grooves, clamp the plastic tube 2 in between, tighten the screws 31, and drive the elongated splints with arc-shaped grooves 30 deform the plastic tube 2 clips; Figure 5 and Figure 6 The corrugation of the elongated splint 30 with an arc-shaped groove in contact with the plastic tube 2 is made into a smooth arc-shaped chamfer 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com