Control method and control device suitable for full-frequency-conversion compressor parallel unit

A frequency conversion compressor and control method technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that the refrigeration system cannot resume work in time, the feedback link of the compressor is not detected, and the service life of parallel units is reduced. Facilitate design improvement, solve life mismatch, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with specific embodiments.

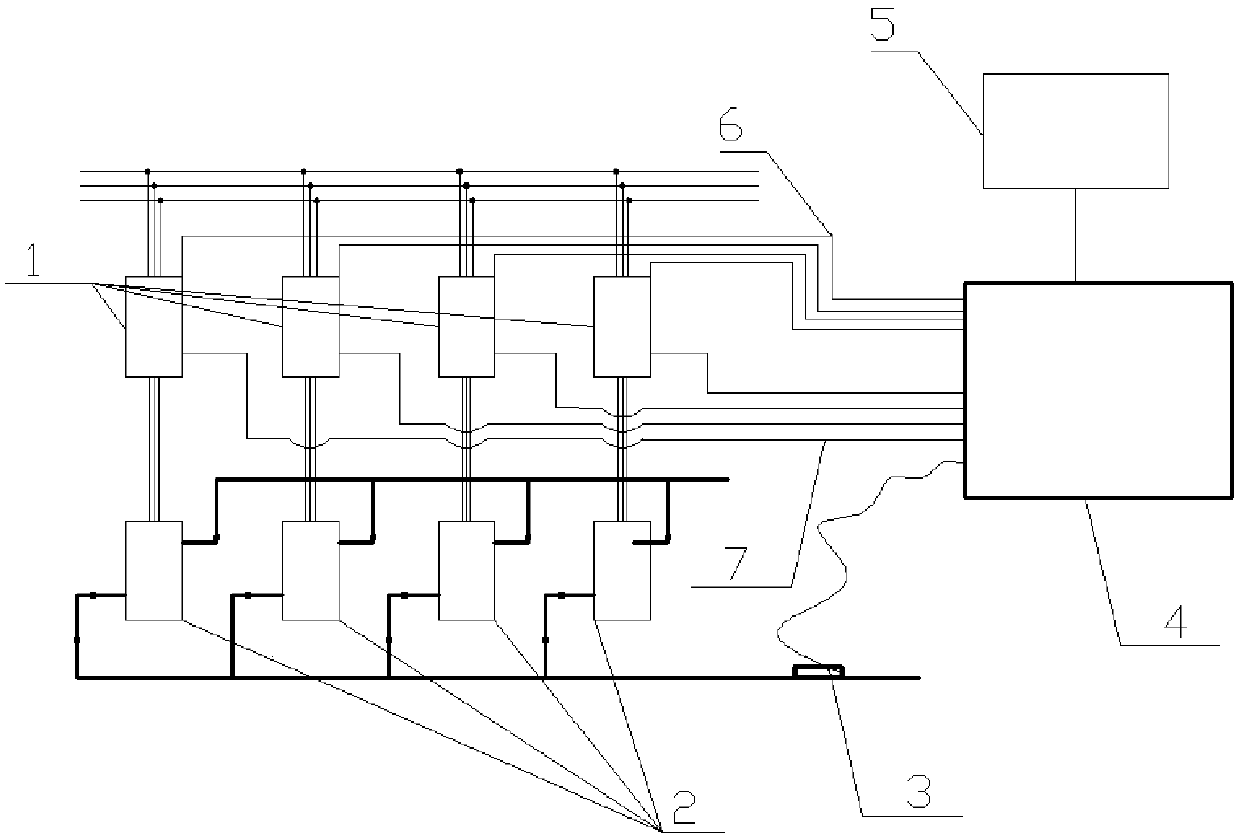

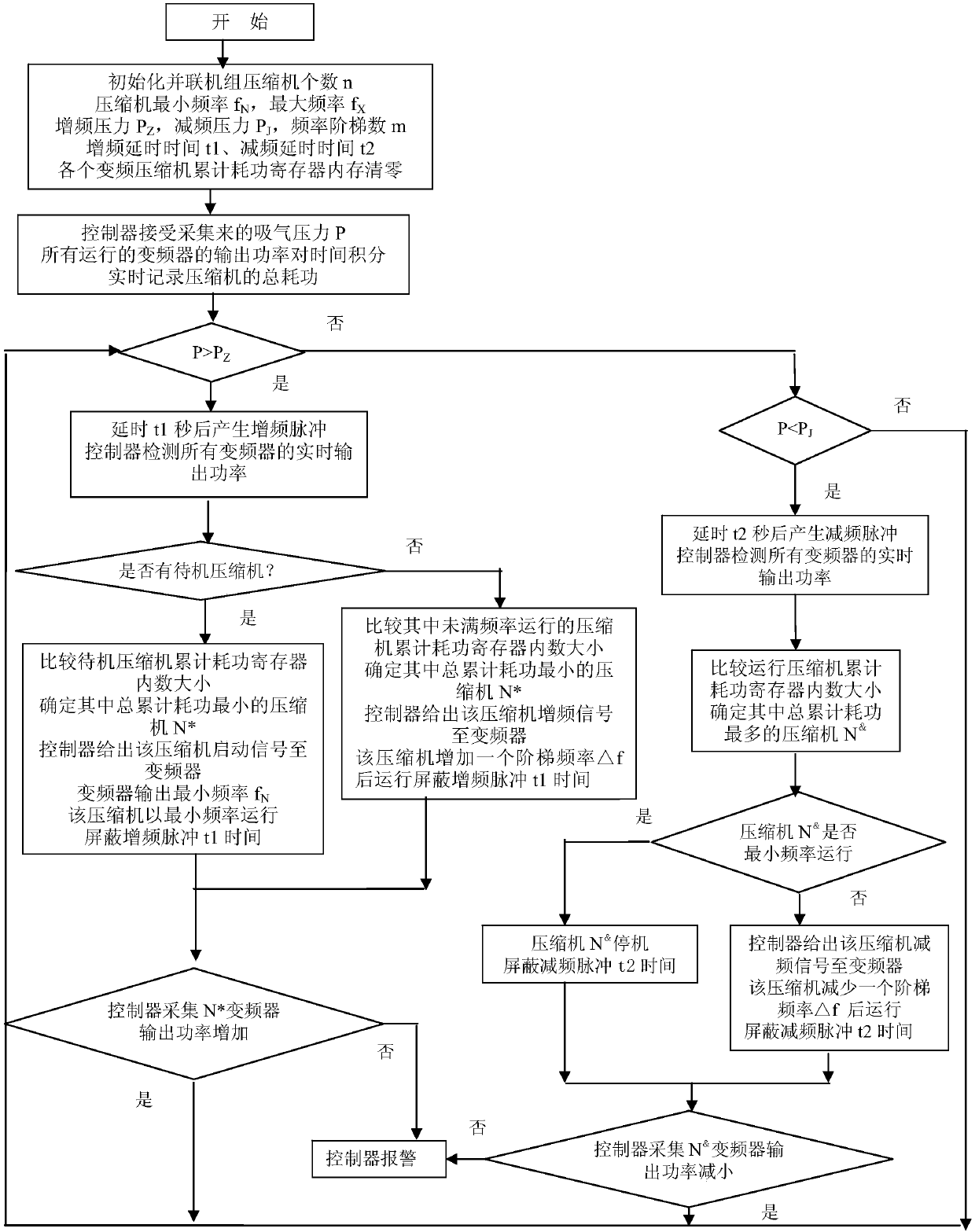

[0055] figure 1 Shown is the structural principle diagram of the control device applicable to the parallel unit of full variable frequency compressors of the present invention, including control line 6, feedback line 7, input device 5, suction pressure sensor 3, controller 4, and power consumption memory. The main circuit of each compressor 2 is respectively installed with a corresponding frequency converter 1, the operating frequency of each compressor 2 is driven by the frequency converter 1, and the output power of each frequency converter 1 is respectively fed back to the input terminal of the controller 4 . The signal output terminal of the input device 5 is connected to the data input terminal of the controller 4 . The output end of the suction pressure sensor 3 is connected to the pressure data input end of the controller 4; the output power output end of the fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com