A size measuring device and method

A measurement device and measurement method technology, applied in measurement devices, instruments, etc., can solve the problems of low maximum speed, low measurement speed, and large influence of object color, so as to reduce the amount of data and improve the measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

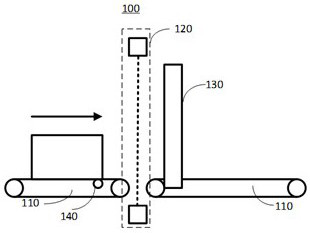

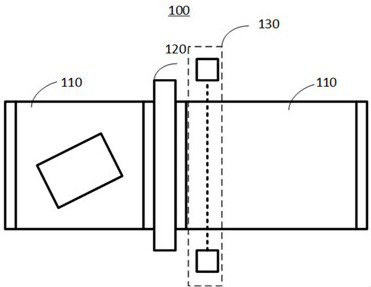

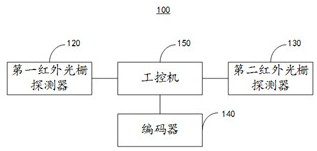

[0032] An embodiment of the present invention provides a size measuring device 100 for measuring the volume of an object. see figure 1 and figure 2 , is a schematic structural diagram of the dimension measuring device 100 provided by the embodiment of the present invention. The dimension measuring device 100 includes two conveyor belts 110 , a first infrared grating detector 120 , a second infrared grating detector 130 , an industrial computer 150 and an encoder 140 . Wherein, the first infrared grating detector 120 is arranged horizontally between two conveyor belts 110 , and the second infrared grating detector 130 is vertically arranged on the conveyor belt 110 . see image 3 , is a block diagram of the circuit structure of the dimension measuring device 100 provided by the embodiment of the present invention. The first infrared grating detector 120 , the second infrared grating detector 130 and the encoder 140 are all electrically connected to the industrial computer ...

no. 2 example

[0061] see Figure 6 , Figure 6 It is a flow chart of a size measuring method provided by a preferred embodiment of the present invention. It should be noted that the basic principles and technical effects of the dimension measurement method provided by this embodiment are the same as those of the above-mentioned embodiment. For a brief description, the part not mentioned in this embodiment can refer to the Corresponding content. The method for measuring the size of the motor speed regulating device includes:

[0062] Step S501 : Use a first infrared grating detector 120 to collect position information of items to be conveyed on a conveyor belt 110 according to a preset first frequency and transmit the position information to an industrial computer 150 .

[0063] Step S502: Using the industrial computer 150 to determine a plurality of position coordinates of the item to be conveyed based on the position information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com