Integral laser induction acoustic surface wave defect detection device

A technology of laser induction and surface acoustic wave, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low detection efficiency and inconvenient operation, and achieve convenient and flexible operation, convenient on-site operation, and defect The effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

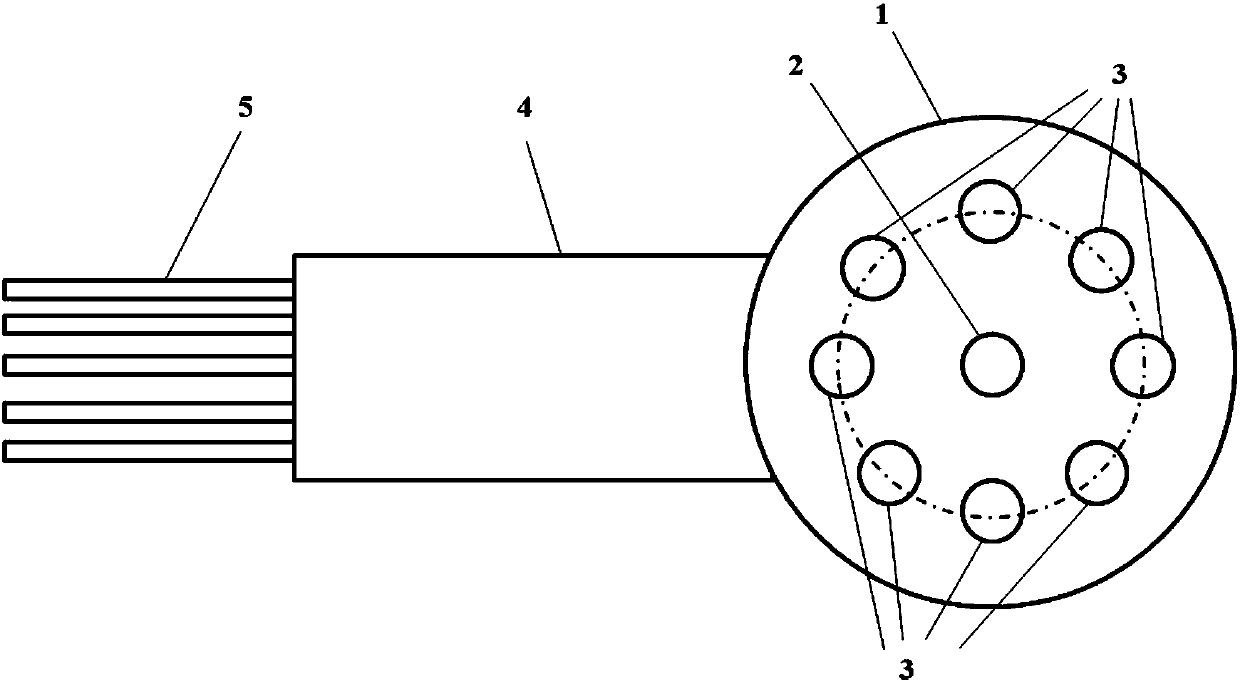

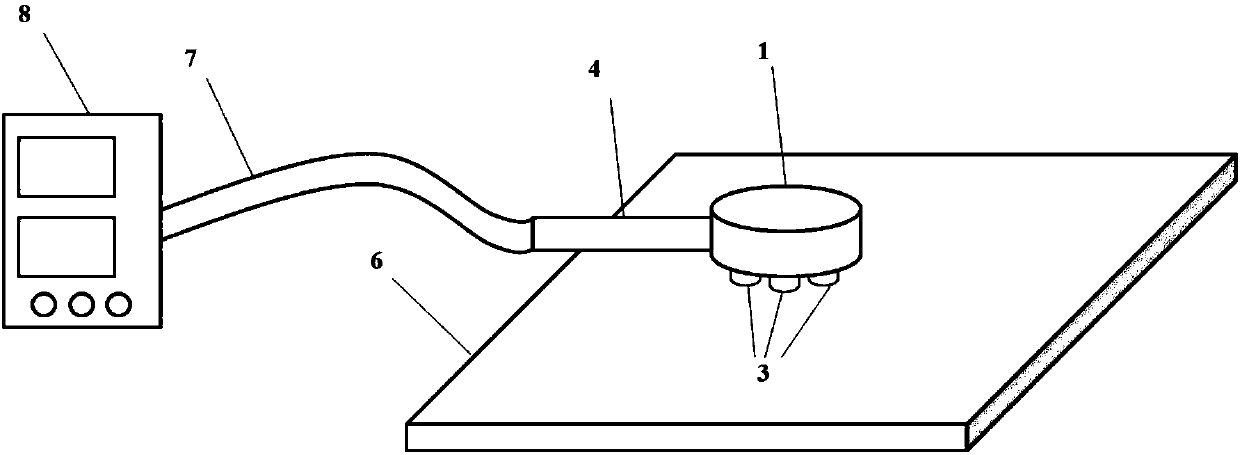

[0025] This embodiment provides an integrated laser-induced surface acoustic wave defect detection device, see attached figure 1 and 2 , including: detection head 1, support arm 4, optical fiber bundle 5, protective cover 7 and detector 8;

[0026] The center of one end face of the detection head 1 is provided with a pumping laser emission port 2, and eight detection laser ports 3 are evenly distributed along the circumference of the pumping laser emission port 2; the shape of the detection head 1 is circular;

[0027] The support arm 4 is a cylindrical shell or a rectangular shell;

[0028] The number of detectors 8 is the same as the number of detection laser emission ports 3;

[0029] The protective cover 7 adopts a hose;

[0030] The optical fibers in the optical fiber bundle 5 are in one-to-one correspondence with the pumping laser emission port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com