Low-frequency array eddy probe

An eddy current probe and array technology, applied in the direction of material magnetic variables, etc., can solve problems such as corrosion of the inner wall of the heating surface tube, batch detection of defects, etc., and achieve the effects of avoiding missed detection of defects, good effect, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

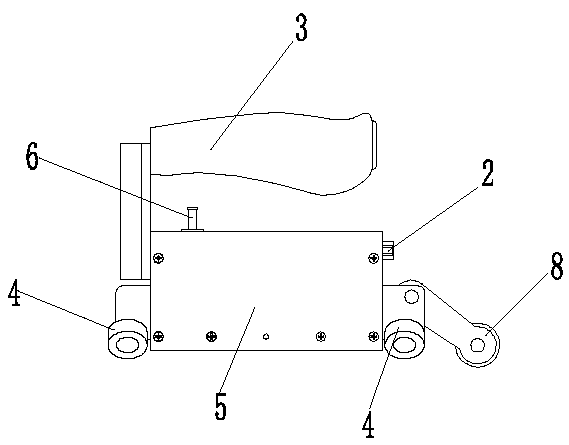

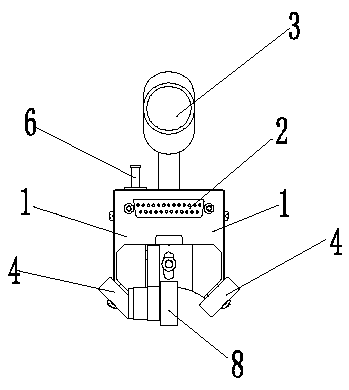

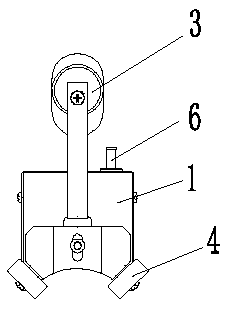

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Depend on Figure 1-7 Given, the present invention includes a housing 1, the housing 1 is a hollow structure, the bottom plate 1a section of the housing 1 is an upwardly concave arc shape, the two sides of the bottom plate 1a are provided with guide rubber wheels 4, in the housing 1, in A plurality of detection coils 11 are evenly distributed on the bottom plate 1a along the arc-shaped circumferential direction of the same radial section. The detection coils 11 are equipped with a magnetic tank 10 for eliminating space scattering leakage flux. There is an excitation coil 7, a shielding coil 9 for focusing the magnetic circuit is arranged between the excitation coil 7 and the detection coil 11, an amplifier 12 is arranged inside the casing 1, a probe socket 2 is arranged outside the casing 1, and each detection coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com