Novel method for modelling and monitoring batch process of chemical engineering

A chemical industry, a new type of technology, applied in the field of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Take the waste treatment gasifier as an example:

[0067] The gasifier for waste treatment is a common chemical batch reaction process, which contains many process variables, and the model proposed by the present invention can be effectively used.

[0068] Step 1. Establish a system model of the reaction process of the waste treatment gasifier. The specific steps are:

[0069] 1.1 Obtain the measurement data of the garbage disposal process, expressed as:

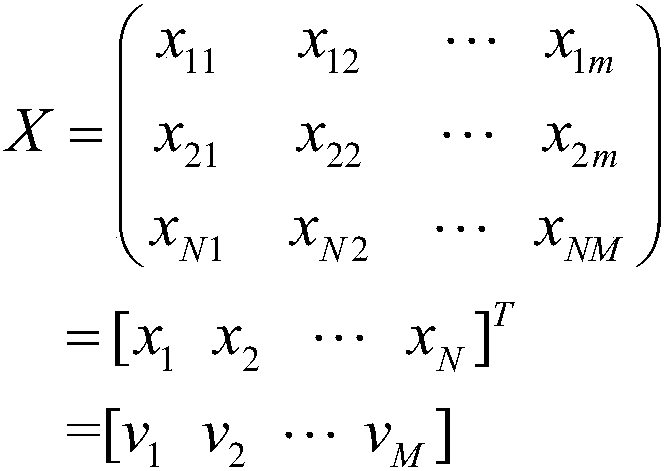

[0070]

[0071] v m =[x 1m x 2m …x Nm ] T (m=1,2,...,M)

[0072] In the formula, X represents the data array obtained in the process, N represents the number of data samples in the process, M represents the number of process variables, m represents the mth process variable in the process, and x 1 x 2 …x N Represent the 1st, 2nd,...,N sample data vectors, v 1 v 2 … v M represent the 1st, 2nd,...M process variables respectively. T stands for transpose notation.

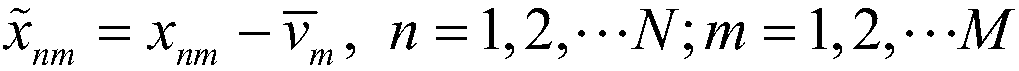

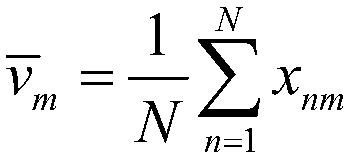

[0073] 1.2 Centralize the data in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com