SPC (statistical process control)-based linkage control method and system

A technology of linkage control system and control diagram, applied in general control system, control/regulation system, program control and other directions, can solve the problems of inability to achieve real-time and linkage, reduce operation efficiency, long time difference, etc., and achieve a friendly interface , to achieve the effect of linkage and reduce the requirements of professionalism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

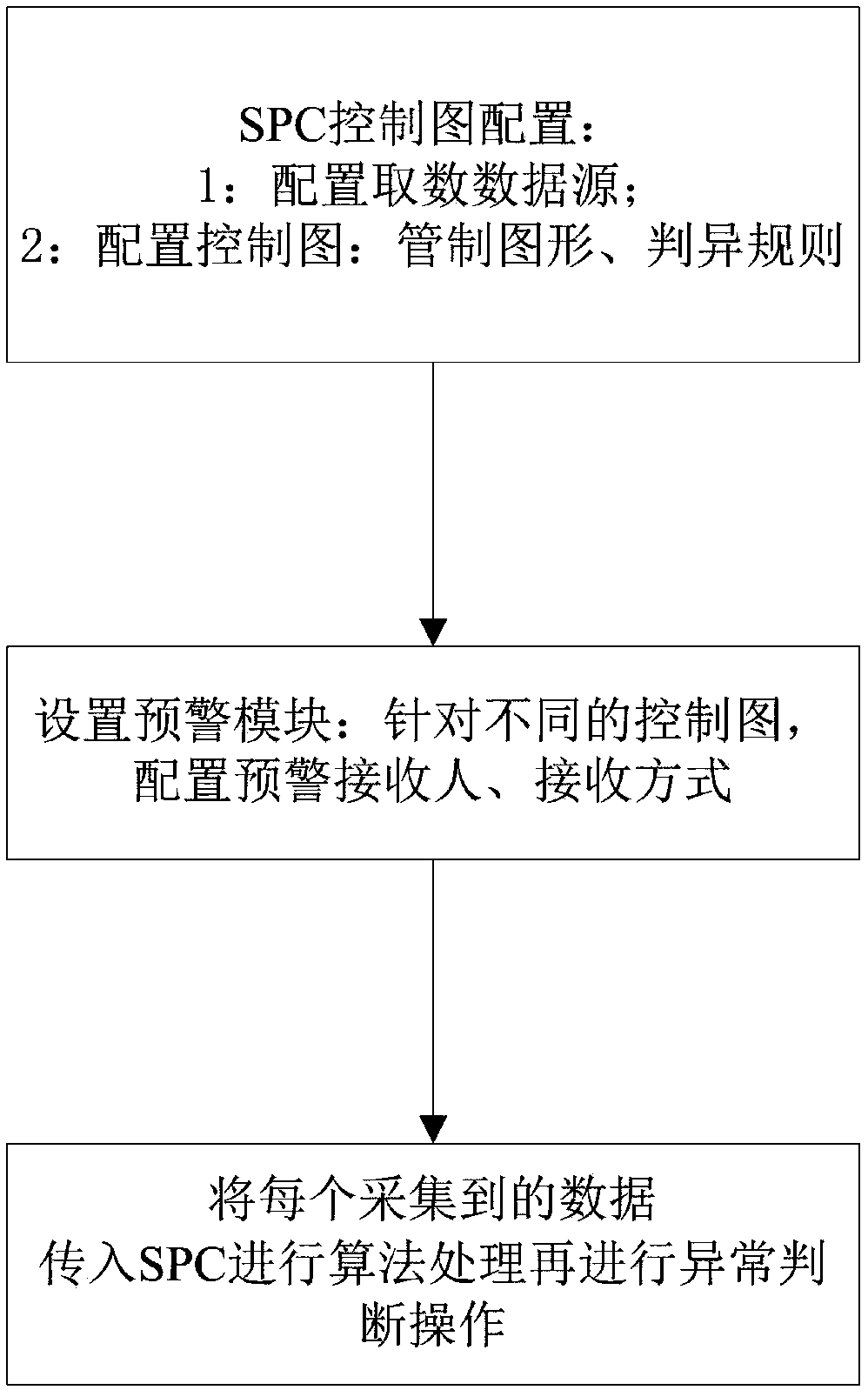

[0031] see figure 1 Shown, the linkage control method based on SPC of the present invention comprises:

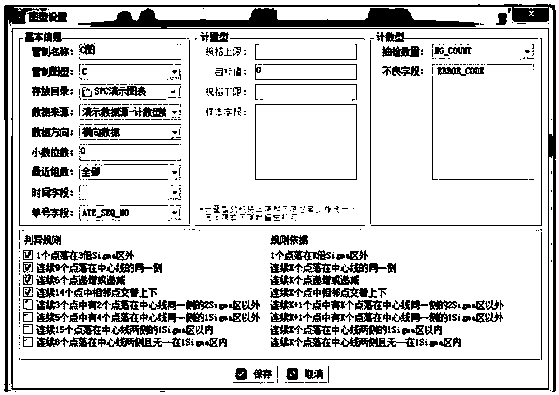

[0032] Step S1, configure the discrimination data source, data algorithm graph and discrimination rules through the configuration module in the SPC system, and configure the actual business needs to be controlled based on the configured discrimination data source, data algorithm graphics and discrimination rules Control Charts;

[0033] Configure the early warning notification object and early warning method through the early warning module in the SPC system;

[0034] Step S2. During the production process, the data acquisition equipment transmits the data collected during the process of the product to the SPC system in real time. When the SPC system receives the data, it immediately makes a statistical judgment according to the configuration result of the configuration module. If the judgment result If it is unqualified, an early warning will be triggered, and the early ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com