High-strength fireproof and anti-interference cable

A high-strength, high-strength cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unstable cable core position and structure, increase compressive strength and environmental high and low temperature resistance, enhance overall heat resistance, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

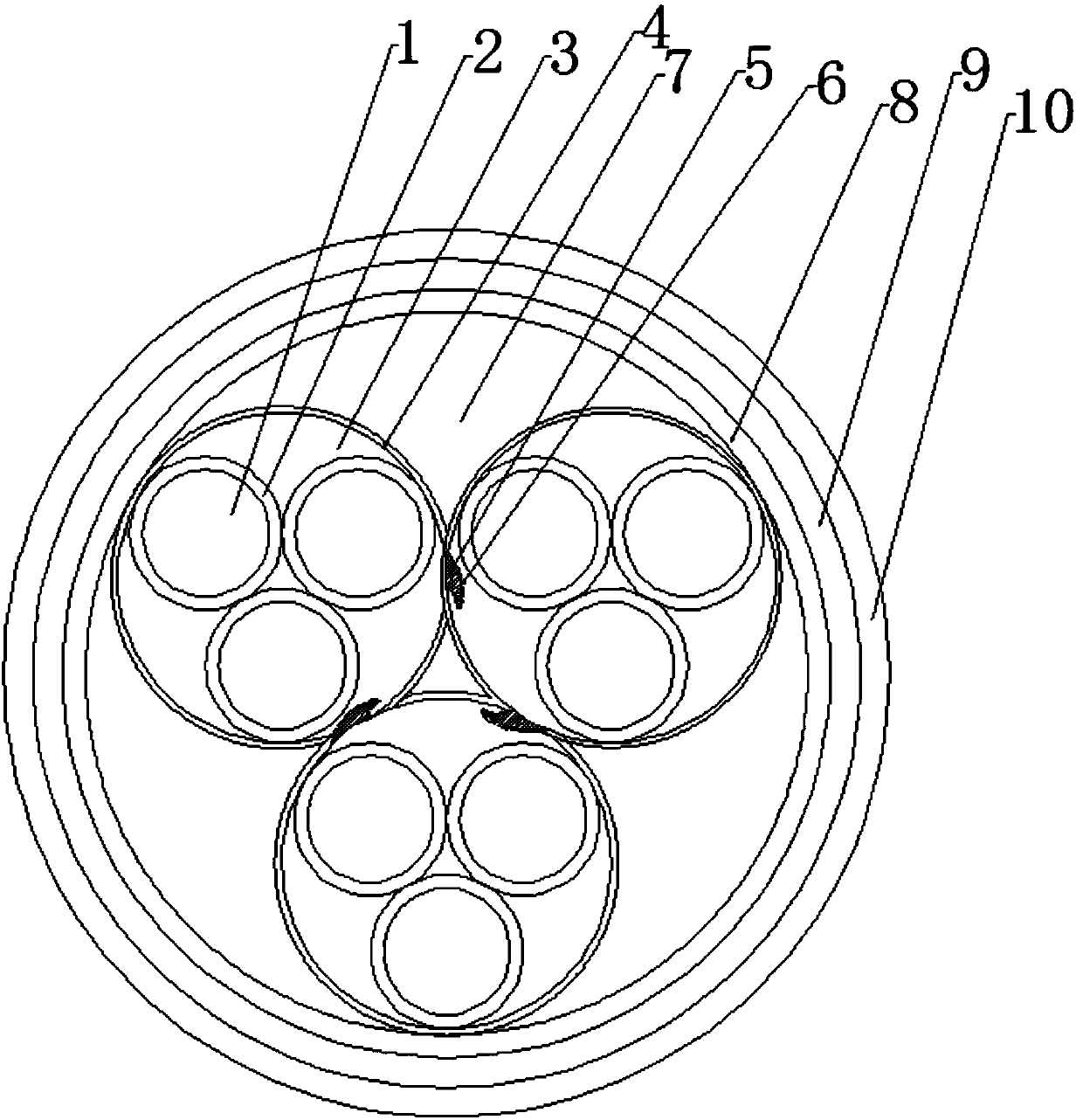

[0021] A high-strength fireproof and anti-interference cable includes a plurality of cable cores and outer protective sheaths, the cable cores are wrapped in the outer protective sheath by the outer protective sheath, the cable cores include an inner shielding layer and are arranged inside the inner shielding layer to form a ring Conductors distributed in a shape array, the outer surface of the conductor is also provided with an insulating layer, and the moisture-proof filler is filled between the insulating layer and the inner shielding layer; the surface of the cable core is also provided with protrusions and matching protrusions Groove, two adjacent cable cores are connected by engaging protrusions and grooves. The protrusion is set in the shape of an eagle's beak, so that after the protrusion is inserted into the groove, it can be locked to avoid slipping. In addition, the raised portion is made of elastic rubber material to facilitate the protrusion to be inserted into th...

Embodiment 2

[0023] On the basis of Embodiment 1, the outer protective sheath is also provided with a refractory mica tape, a copper wire braided shielding layer, and an outer sheath layer concentrically from the inside to the outside, and the outer protective sheath and the cable core are filled with Composite filling. Wherein, the composite filler adopts a mixture of glass fiber and polypropylene, so that the whole has a certain waterproof performance, and also enhances the overall heat resistance and corrosion resistance; the fire-resistant mica tape has good high-temperature fire resistance, It can effectively improve the fire-resistant stability of the cable and the integrity in high temperature and pyrotechnics; the copper wire braided shielding layer can effectively shield external interference signals and ensure the transmission speed and transmission quality of the cable; the outer sheath layer is made of polyvinyl chloride, which can Increase the compressive strength of the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com