Cultivating equipment to which nutritive solution can be continuously supplied

The technology of cultivation equipment and nutrient solution is applied in the field of cultivation equipment that can continuously replenish nutrient solution, and can solve the problems of restricting the popularization and application of soilless cultivation technology, increasing cultivation cost, and high cultivation cost, and achieving reduction in automation control, energy saving, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

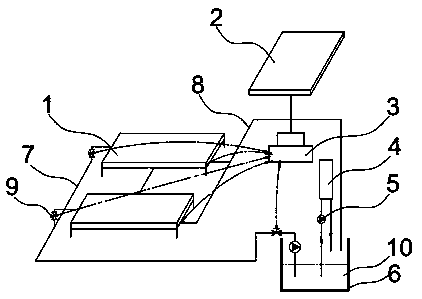

[0023] Such as figure 1 As shown, the cultivation equipment that can continuously replenish the nutrient solution includes: a cultivation tank 1 for placing a cultivation pot 102, and the upper and lower ends of the cultivation tank 1 respectively pass the liquid inlet pipe 7, the liquid outlet pipe 8 and the liquid tank 6 to circulate and transport nutrients The liquid inlet pipe 7 above the liquid tank 6 is provided with a water pump 5 and a solenoid valve 9, and the liquid inlet pipe 7 and the liquid outlet pipe 8 at the upper and lower ends of the cultivation tank 1 are provided with a solenoid valve 9, and the solenoid valve 9 is connected to The line is connected to the industrial computer 3, and the industrial computer 3 is externally connected to the solar panel 2. There are no less than two cultivation tanks 1 in the soilless cultivation equipment, and the cultivation tanks 1 are connected in parallel through connecting pipes, and the industrial computer 3 is used to r...

Embodiment 2

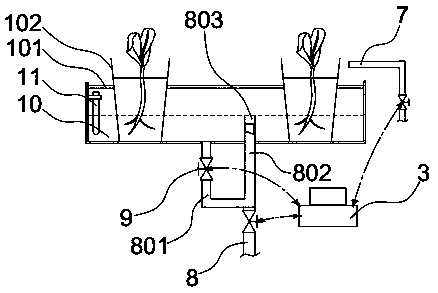

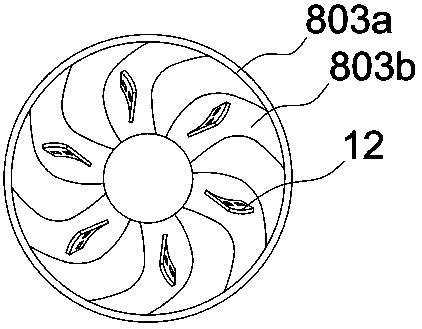

[0025] Such as figure 2 , 3, 4, this embodiment is further optimized on the basis of embodiment 1 as follows: the bottom surface of the cultivation tank 1 is connected with a low-level liquid return pipe 801, and the inside is connected with a high-level liquid return pipe 802, and the top surface of the low-level liquid return pipe 801 is connected to the The bottom surface of the cultivation tank 1 is flush, the top surface of the high-level liquid return pipe 802 is 4-8 cm higher than the bottom surface of the cultivation tank 1, preferably 7 cm, and the low-level liquid return pipe 801 and the high-level liquid return pipe 802 below the cultivation tank 1 are connected to form "Mouth" shape, the joint is connected with the liquid outlet pipe 8 and is provided with a solenoid valve 9, so that the nutrient solution 10 enters the cultivation tank 1. At this time, the solenoid valve 9 on the low return liquid pipe 801 below the cultivation tank 1 is closed. state, the liquid...

Embodiment 3

[0031] Such as Figure 5 , 6 , 7, the top of the liquid tank 6 is connected with a sterilizer 4, and the bottom of the sterilizer 4 is respectively provided with a sterilized liquid suction pipe 4a positioned in the liquid tank 6 and a sterilized liquid outlet pipe 4b positioned at the top of the liquid tank 6, and the sterilized liquid suction pipe 4a upper part is positioned at sterilizer 4 inside and top surface and sterilizer 4 bottom surface intervals are preferably 12cm, and the nozzle of sterilizing liquid outlet pipe 4b is flush with sterilizer 4 internal bottom surface, and sterilizer 4 bottom is provided with adsorption plate 4c, and top is provided with for The sterilized ultraviolet sterilizing lamp 4e is controlled by the industrial computer 3. There are some adsorption balls 13 floating on the liquid surface of the nutrient solution 10, and the side of the sterilizer 4 is connected with a sealed door 4d. The disinfection suction pipe 4a is connected with a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com